Flexible wireless charging material and manufacturing method

A wireless charging and flexible technology, applied in coil manufacturing, circuits, inductors, etc., can solve problems such as poor product integrity, poor product flexibility, and inability to organically combine electromagnetic induction coils with products, so as to overcome poor integration and realize intelligence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

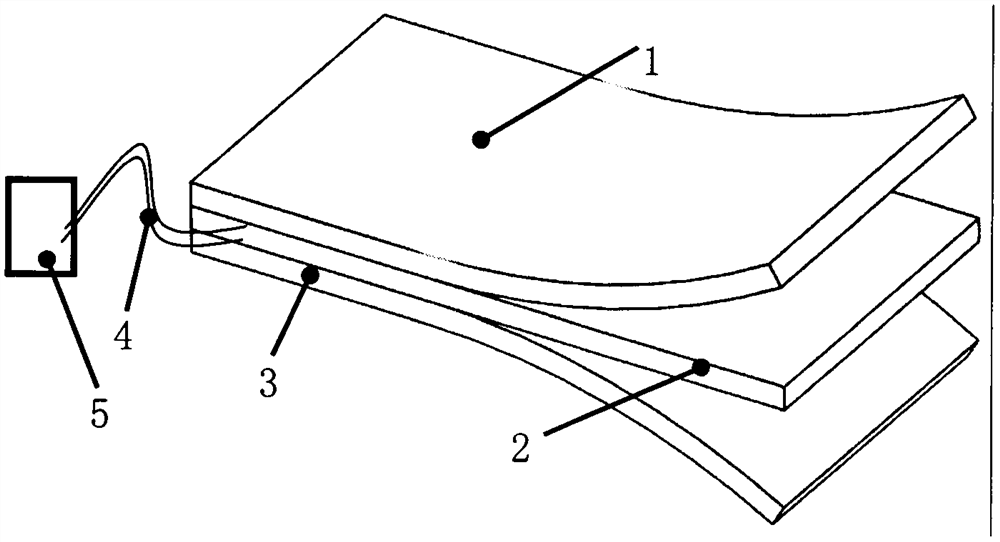

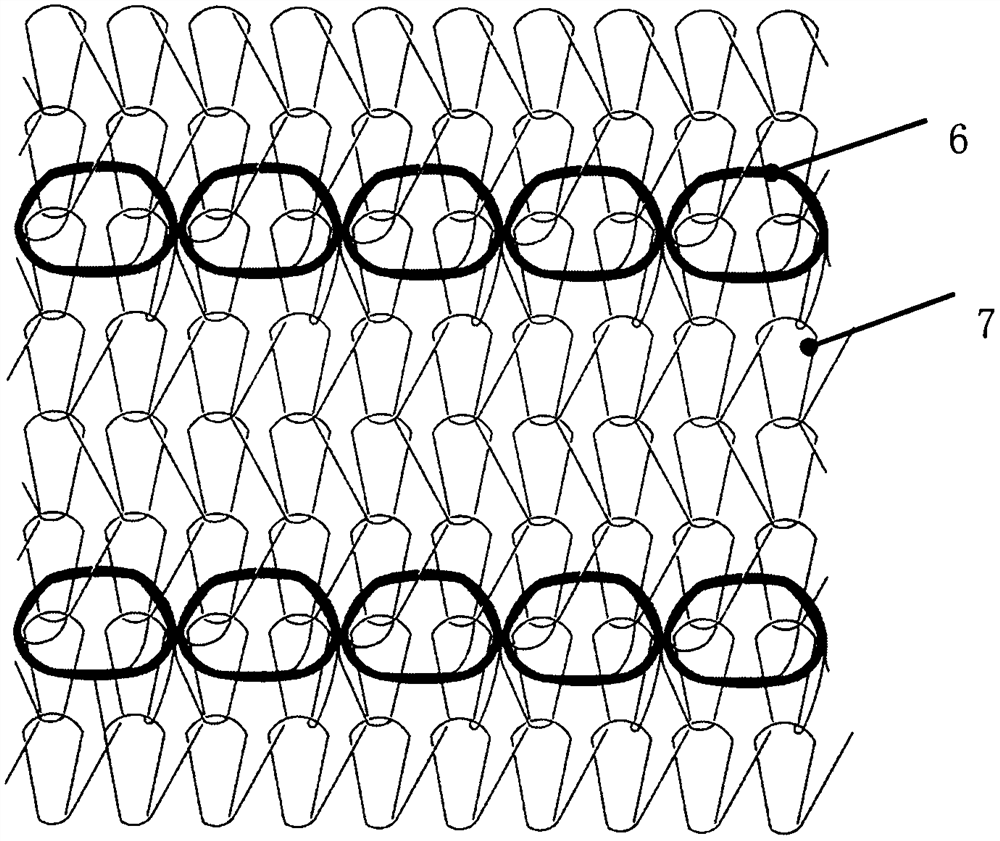

[0029] A flexible wireless charging material, the structure of which includes an upper cladding layer, a wireless charging layer, a lower cladding layer, a power cord and a wireless charging control module, and a wireless charging layer is arranged between the upper cladding layer and the lower cladding layer. The wireless charging layer is connected to the wireless charging control module through the power line, such as figure 1 shown. Among them, the wireless charging layer is a warp-knitted structure, the wireless charging transmitting coil is formed as a whole during the knitting process of the warp-knitted structure, and the number of winding turns of the wireless charging coil is 4 turns. In the coil wale direction, a row of charging coils is arranged every two knitting courses, such as figure 2 shown. The wireless charging module adopts the 200W / 48V power supply output high-power wireless charging module XKT901-19 product currently available in the market.

[0030] ...

Embodiment 2

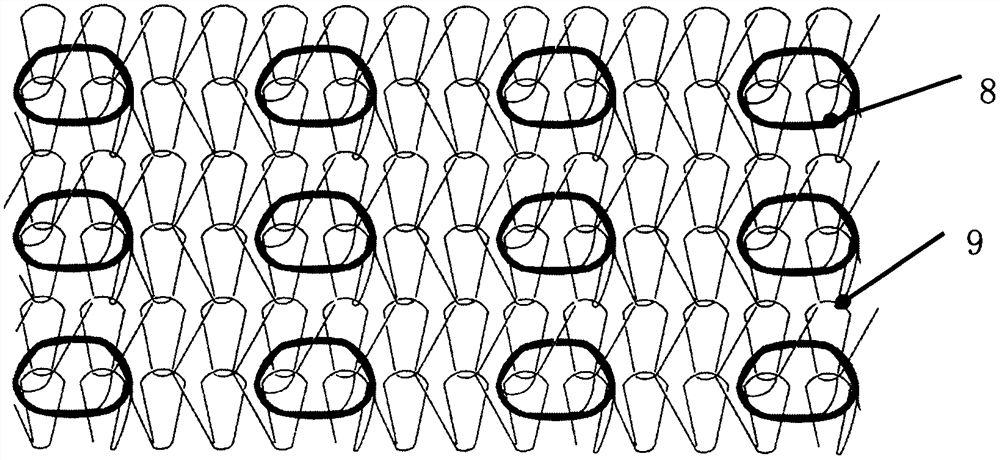

[0037] According to the process, the wireless charging layer uses the textile yarn as the braided yarn and the enamelled copper wire as the tuck wire, and adopts the continuous pressure-free warp knitting technology to form a winding number of 4 turns, and forms every 2 turns in the direction of the course. A whole fabric with 1 row of charging coils arranged in wales, its structure is as follows image 3 shown. Other processes are as described in Example 1.

Embodiment 3

[0039] According to the process, the wireless charging layer uses the textile yarn as the weaving yarn and the enamelled copper wire as the tuck wire, and adopts the continuous pressure-free warp knitting technology to form a winding number of 7 turns, and is formed in the course and wale direction of the coil. The overall fabric with a row of charging coils arranged every two wales, its structure is as follows Figure 4 shown. Other processes are as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com