Chemical fiber static electricity removing device

A static electricity removal device and technology of chemical fiber yarns, applied in the direction of static electricity, electrical components, transportation and packaging, etc., can solve problems such as insufficient protection measures, untidy chemical fiber yarns, and imperfect automatic control instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

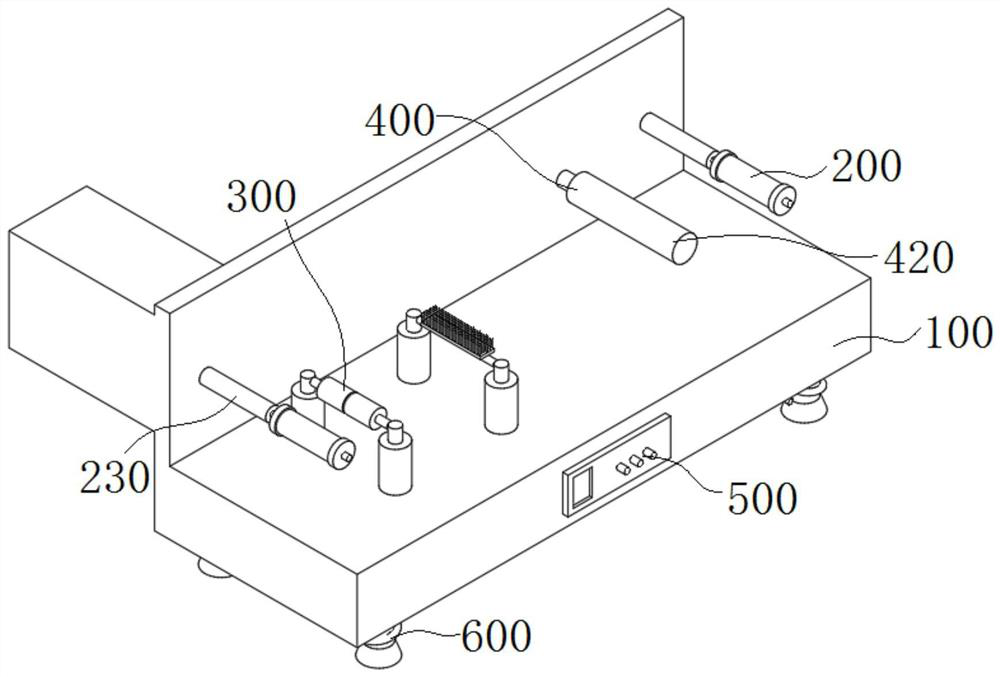

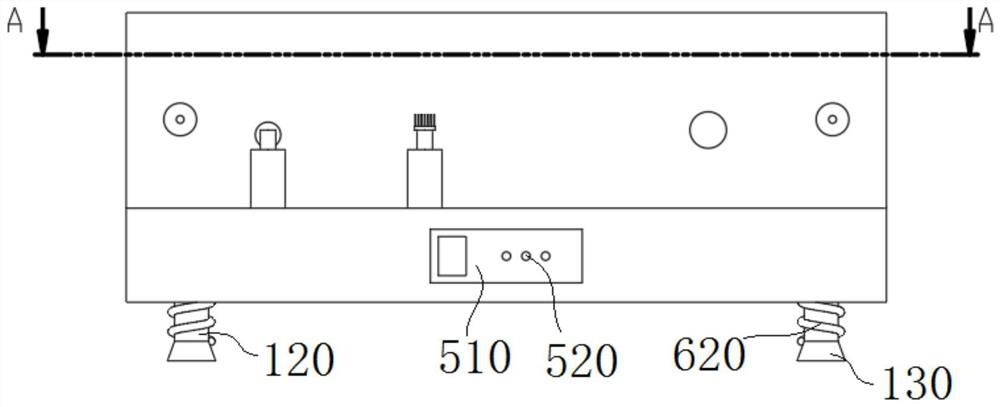

[0028] Please refer to figure 1 As shown in -4, the present invention is a chemical fiber thread static removal device, including a load-bearing structure 100, a transmission structure 200, a finishing structure 300, a processing structure 400, a control structure 500 and a protection structure 600, and the load-bearing structure 100 includes a workbench 110 and a support The column 120 and the lower surface of the workbench 110 are provided with several installation grooves, and the side surfaces of several support columns 120 are respectively connected with several installation grooves. One side surface is welded with the side surface of the workbench 110, the motor box 210 is a hollow structure, the motor 220 is installed inside the motor box 210, the side surface of the motor 220 is provided with a rotating groove, and the rotating shaft 230 is rotatably matched with the rotating groove, and the finishing structure 300 includes The connecting columns 310 and the connecting...

Embodiment 2

[0036] Please refer to figure 1 Shown in -4, the present invention is a kind of chemical fiber yarn removing static electricity device, and support column 120 and support foot 130 mainly play the purpose of supporting device, and wire transfer roller 250 rolls the chemical fiber yarn just produced, and wire take-up roller 240 passes through motor 220 Rotate to collect the processed chemical fiber yarn. When the chemical fiber yarn passes through the finishing roller 330, it will be tensioned therein. When the chemical fiber yarn passes through the static elimination roller 420, the leather set on it can eliminate static electricity. The control knob 520 mainly controls The speed of the motor 220 is used to control the speed of the take-up roller 240 and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com