Gypsum line laminating device with film breakage-proof mechanism

A technology of gypsum line and film coating device, which is applied in the directions of packaging, winding strips, thin material processing, etc., can solve the problems of many process steps, low efficiency, and inability to fit films, so as to save process steps and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

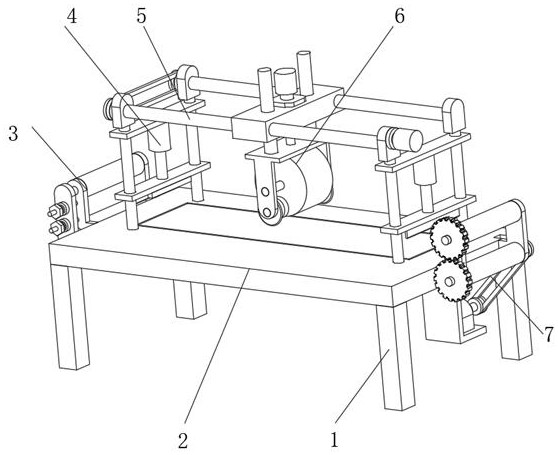

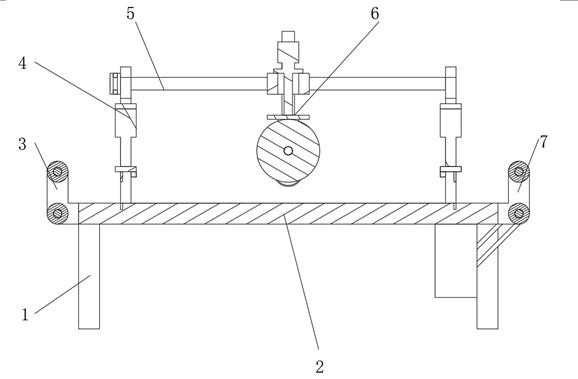

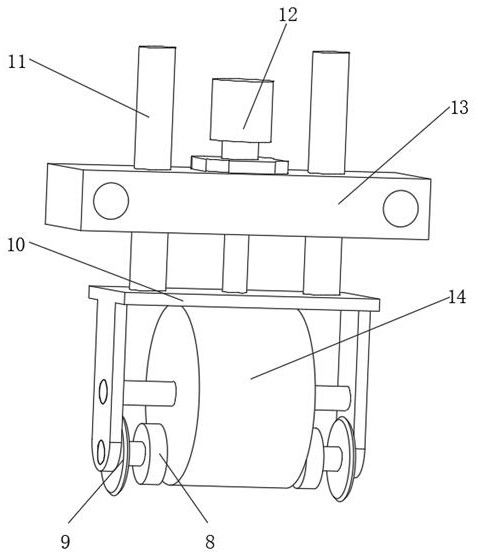

[0035] A gypsum line coating device with a film anti-breaking mechanism, such as figure 1 , 2, 3, and 4, including the workbench 2 fixed on the ground through the legs 1, the outer walls of the symmetrical sides of the workbench 2 are respectively provided with a passive film feeding mechanism 3 and an active scrap winding mechanism 7, and the top of the workbench 2 The outer wall is provided with a main moving mechanism 5, and the outer walls on both sides of the main moving mechanism 5 are provided with a coating mechanism 1 4, and the bottom outer wall of the main moving mechanism 5 is provided with a coating mechanism 2 6, and the coating mechanism 2 6 includes two A heat-sealing roller 8, two hobs 9, a slider one 13 and a compacting roller 14, the heat-sealing roller 8 is an electric heating roller, and the inner wall of the slider one 13 is slidably connected with two slide bars-11 , the bottom outer wall of the slide bar 11 is fixed with a lifting seat 10 by bolts, and...

Embodiment 2

[0039] A gypsum line coating device with a film anti-breaking mechanism, such as Figure 5 As shown, in order to solve the problem of reliable loading and unloading; the present embodiment makes the following improvements on the basis of embodiment 1: the outer walls of one side of the two film feeding shafts 25 are all connected with friction plates 26 by keys, and the support one 23 The outer wall is welded with two screw rods 31, and the outer wall of the screw rod two 31 is provided with a friction plate 27, and the outer wall of the screw rod two 31 is threadedly connected with an adjusting nut 28, and the outer wall of the screw rod two 31 is provided with a gasket 30, and the adjusting nut 28 and A spring 29 is arranged between the pads 30; since the gypsum lines are generally longer, the film span between the film roll 24 and the take-up roller 34 is also longer, and its own weight will cause the film roll 24 to rotate, so that the two layers of film stick to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com