Backwashing valve

A technology of backwashing and valves, which is applied in the direction of valve details, multi-way valves, valve devices, etc., can solve the problems of large amount of backwashing valves, high manufacturing costs, complex structures, etc., and achieve improved utilization and low manufacturing costs , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

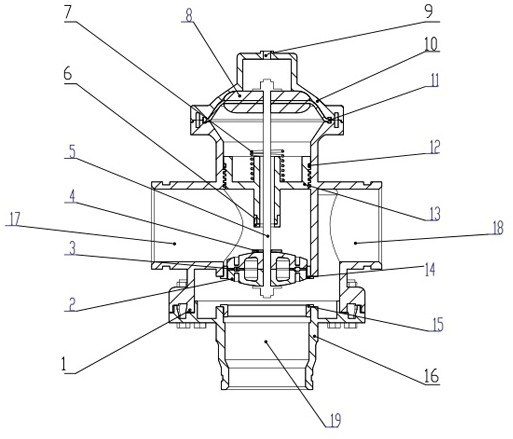

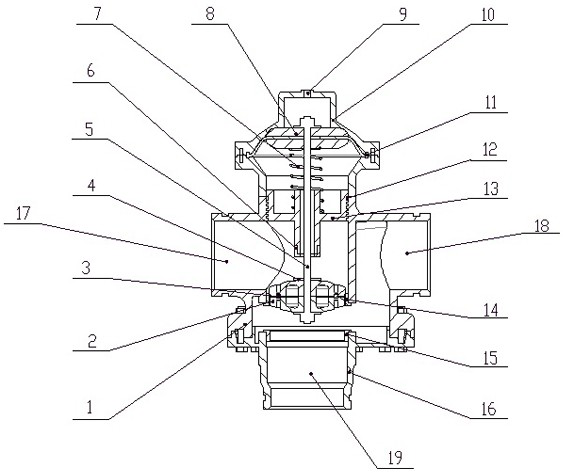

[0024] The water inlet 17 is connected to the water inlet pipe, one outlet 18 is connected to the water outlet pipe and the filter, the outlet pipe is provided with a ball valve as a control switch, and the lower flushing port 19 is connected to the inlet of the sewage well. High pressure is injected into the cavity, and the high pressure drives the diaphragm 11 and the sealing chuck 8 to move downward and compresses the spring 7, and the sealing chuck 8 drives the connecting rod 5 to squeeze the valve plug 2 so that the valve plug 2 moves downward and is tightly combined with the lower valve seat 16 , cut off the flushing port 19 of the lower valve body 16, and the drain port 18 of the upper valve body 1 is normally open at this time. The port 9 is emptied to reduce the pressure of the control chamber, the spring 7 returns to the initial state, the connecting rod 5 is driven upward by pulling the sealing chuck 8 and the diaphragm 11, and the valve plug 2 is driven by the conne...

Embodiment 2

[0026] The water inlet 17 is connected to the water inlet pipe, and the three outlets 18 are respectively connected to three outlet pipes and filters. Each outlet pipe is equipped with a ball valve as a switch, and the bottom flushing port 19 is connected to the sewage well inlet. Hydraulic control is performed in the filtering mode. The valve port 9 is pressurized, the control chamber injects high pressure, the high pressure pushes the diaphragm 11 and the sealing chuck 8 to move downward and compresses the spring 7, and the sealing chuck 8 squeezes the connecting rod 5 to drive the valve plug 2 so that the valve plug 2 and the lower The valve seat 16 is tightly combined to block the flushing port 19 of the lower valve body 16. At this time, the drain port 18 of the upper valve body 1 is normally open. When there are many impurities accumulated on the filter layer, the resistance of the incoming water passing through the filter layer is relatively large. The hydraulic control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com