A sewage treatment method and device with both deep nitrogen and phosphorus removal and mud-water gravity separation

A technology of advanced treatment and gravity separation, applied in biological water/sewage treatment, water/sludge/sewage treatment, biological treatment devices, etc. The effect of large hydraulic load, long backwash interval and reduced treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

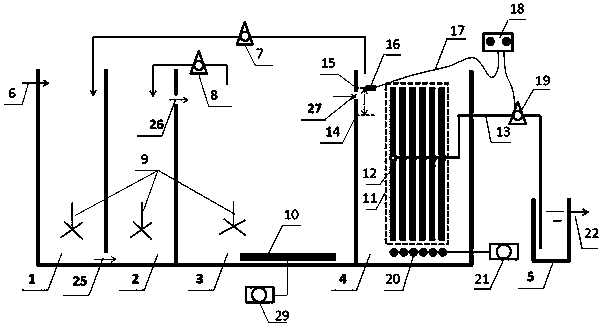

[0053] Such as figure 1 As shown, a kind of sewage treatment device of the present invention has both deep denitrification and dephosphorization and gravity separation of mud and water, including agitation pool 1, agitation second pool 2, aeration / stirring alternate pool 3, oxygenation pool 4, mud water gravity Separation device: The mud-water gravity separation device includes a membrane module 11, a clear water tank 5 and a backwashing device. The bottoms of the first stirring pool 1 and the second stirring pool 2 are connected, and both the first stirring pool 1 and the second stirring pool 2 are equipped with independent stirring devices 9 . The aeration / stirring alternate tank 3 is equipped with a stirring device 9, a first aeration device 10 and a mud water internal circulation device 8 (so that part of the mud water can flow back from the aeration / stirring alternate tank 3 to the second stirring tank 2), the first aeration The device is connected to the first blower 29...

Embodiment 2

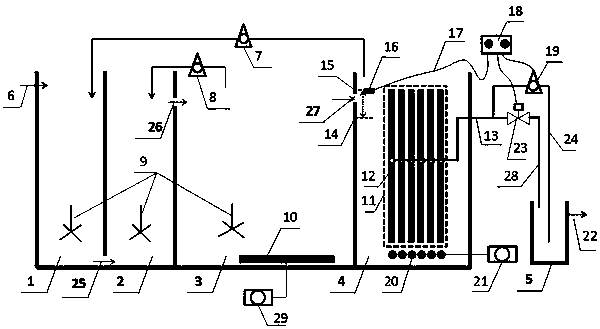

[0070] This embodiment is the second embodiment of the present invention, and the difference from Embodiment 1 is that the water collection channel includes a water collection pipe 13, an electric valve 23 and a filtrate outlet pipe 28 that communicate with each other, and the water collection pipe 13 and the low liquid level line 14 are in the At the same level, the backwash suction pipe 24 is provided with a backwash pump 19, and the electric valve 23 is connected with the backwash pump 19 and the controller 18; the membrane element 12 is connected with the water collection pipe 13, and the filtrate outlet pipe 28 is connected with the clear water tank 5 Through, the backwash suction pipe 24 communicates with the clear water tank 5. All the other parts are identical with embodiment 1 with connection mode, as figure 2 shown. When the liquid level reaches the high liquid level line 15, the backwash pump 19 is started through the liquid level monitor 16 and the controller 18,...

Embodiment 3

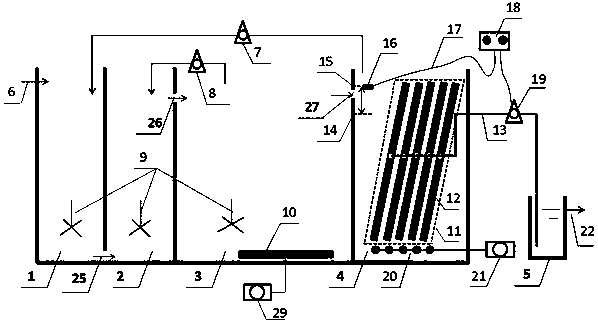

[0072] This embodiment is the third embodiment of the present invention. The difference from Embodiment 1 is that the second aeration device 20 includes an aeration tube, and the membrane element 12 is a flat membrane element ( Figure 6 ), the angle formed by the flat membrane element and the bottom of the oxygenation tank 4 is 50~70°, and the aeration pipe is parallel to the flat membrane element. All the other parts are identical with embodiment 1 with connection mode, as image 3 shown. When the second blower 21 is started, the air bubbles will rise rapidly against the surface of the membrane, which will alleviate membrane fouling and increase the unit membrane flux.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com