Automatic operation method for mixing, sample melting and soot blowing of fire assays

A method of operation, the technology of fire test, applied in the field of melting samples, ash blowing automation, and fire test gold mixing field, can solve the problems of easy inhalation into the inspector's body, affecting the inspector's health, slow manual stirring speed, etc., to achieve improvement. Labor environment, improving detection efficiency and stability of detection data, and reducing the effect of physical expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

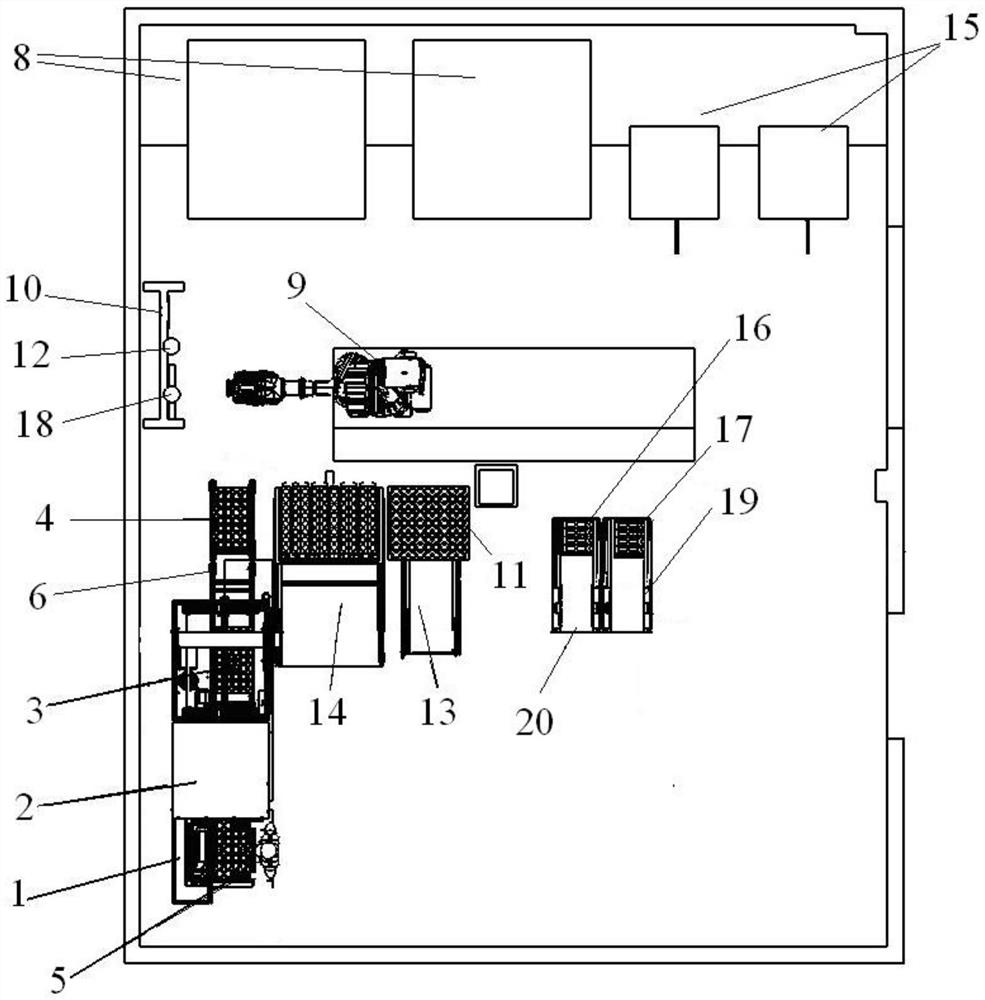

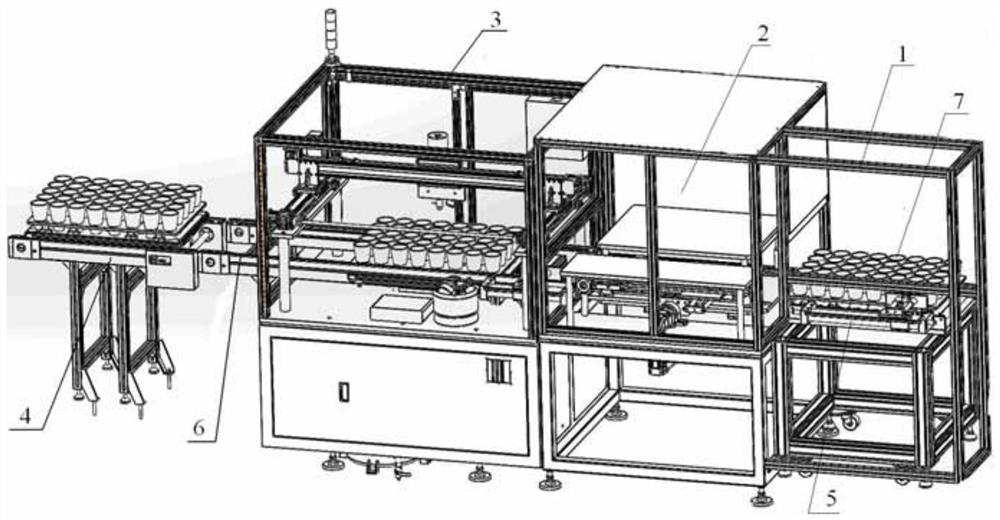

[0060] Include the following steps:

[0061] (1), automatic mixing

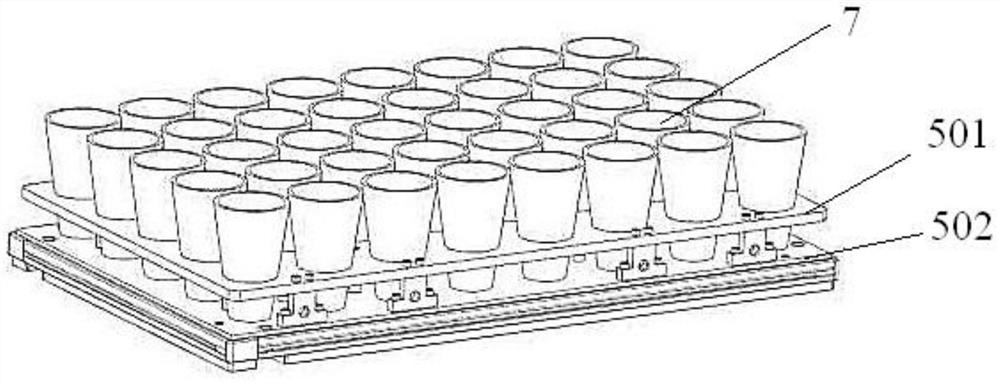

[0062] (1), 40 crucibles 7 completed by the fire test gold method are placed on the crucible tray 5 in the feeding unit 1 in sequence;

[0063] (2), drag the crucible tray 5 to the mixing station 2 for mixing;

[0064] (3), the crucible tray 5 enters the mixing station 2, the mixing station upper cover 205 automatically compresses, rotates, and ends after turning over for 5 minutes, the mixing station upper cover 205 automatically opens 2.5cm, and shakes for 2 minutes, then Automatically compress the upper cover 205 of the mixing station and continue mixing for 2 minutes;

[0065] (4), uniformly mixed material flows to silver nitrate dripping and covering agent covering station 3 by slide rail conveying line 6 and carries out silver nitrate dripping and covering agent covering process;

[0066] (5), after completing the titration and covering process, the tray flows to the mechanical arm picking position 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com