Method for preparing perovskite thin film on surface textured heterojunction battery

A heterojunction cell, perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high cost and slow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following describes several preferred embodiments of the present invention with reference to the accompanying drawings, so as to make the technical content clearer and easier to understand. The present invention can be embodied in many different forms of embodiments, and the protection scope of the present invention is not limited to the embodiments mentioned herein.

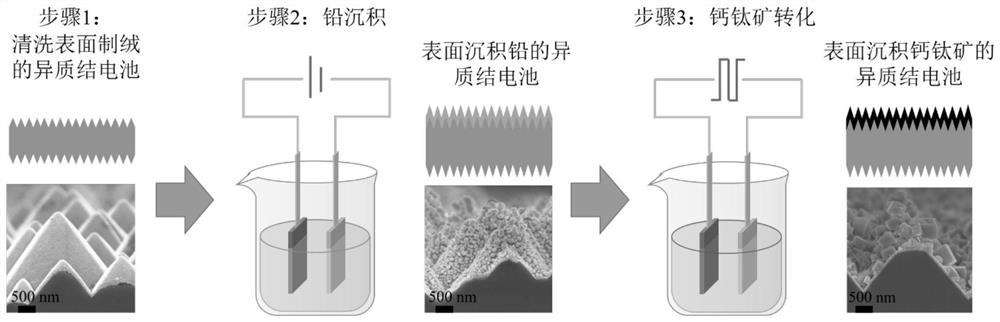

[0037] Such as figure 1 As shown, a preferred embodiment of the present invention realizes the uniform and continuous coverage of the perovskite thin film on the heterojunction battery with surface texture by electrochemical method:

[0038] Step 1. Cleaning of heterojunction cells with textured surface:

[0039] Step 1.1. Place the textured heterojunction cell in an ultrasonic cleaning machine, and clean it with deionized water, acetone, isopropanol, and ethanol for 15 minutes;

[0040] Step 1.2, finally placed under ultraviolet radiation to remove organic pollution and improve hydrophilicity;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com