Aircraft manufacturing material processing device

A material processing and aircraft technology, applied in the field of aircraft, can solve problems such as debris splashing on the ground, inconvenient ground cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

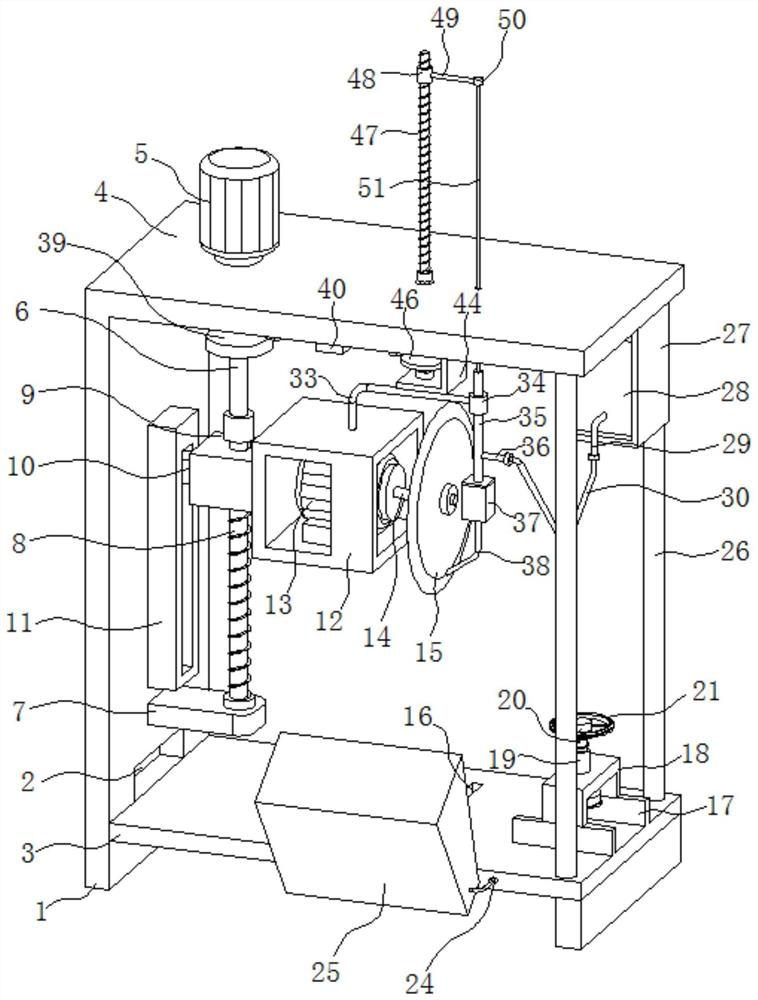

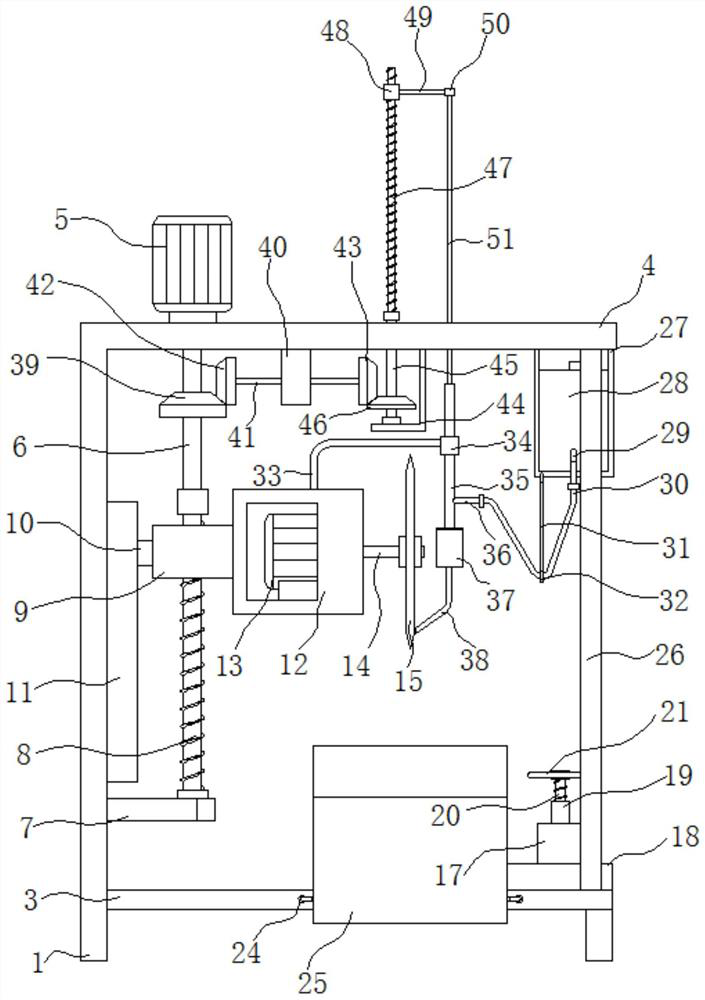

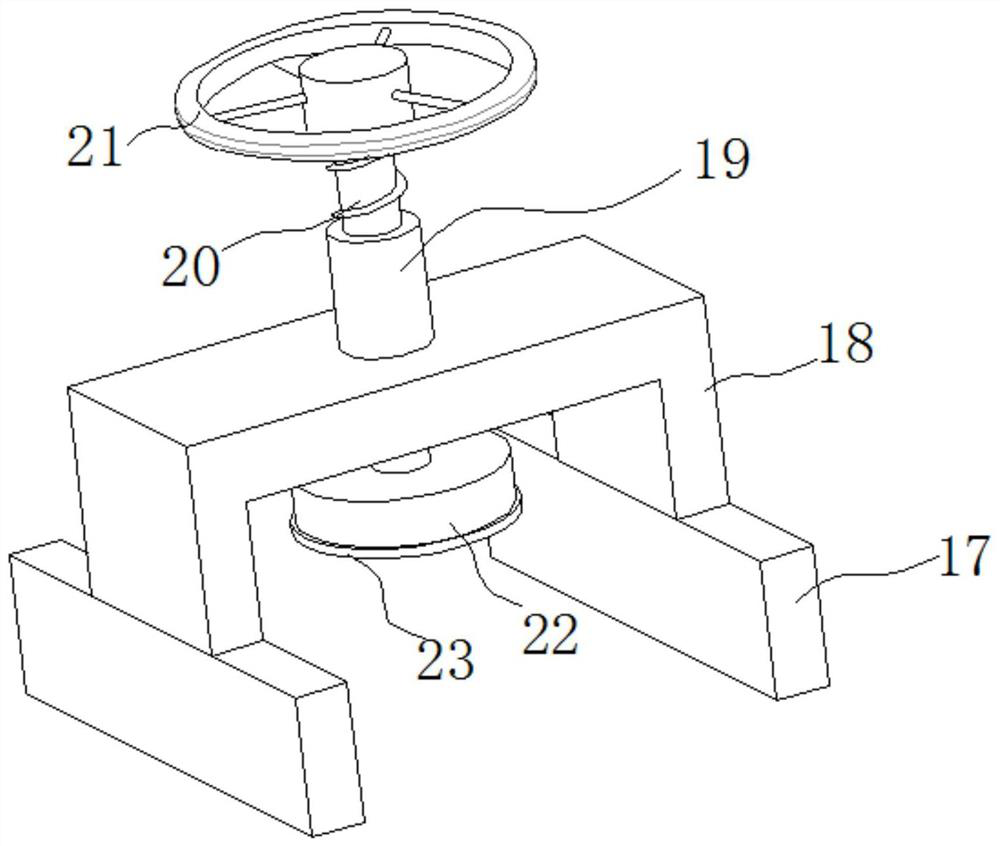

[0021] refer to Figure 1-4 , a material processing device for aircraft manufacturing, comprising a support plate 1, the bottom end of the support plate 1 is connected with anti-skid lines, the support plate 1 is connected with a bottom plate 3, and the side of the bottom surface of the bottom plate 3 away from the support plate 1 is connected with a support Feet, the base plate 3 is provided with a strip hole 2, the inner bottom of the strip hole 2 is flush with the upper surface of the base plate 3, the upper end of the support plate 1 is connected with a top plate 4, and the upper end of the top plate 4 is connected with a first motor 5, The first motor 5 is connected to an external power supply through a wire, and the output end of the first motor 5 is driven to be connected with a first rotating shaft 6, and one end of the first rotating shaft 6 runs through the top plate 4, and one end of the first rotating shaft 6 is connected with a first reciprocating screw 8 for suppo...

Embodiment 2

[0027] When the blade 15 cuts the metal plate, the temperature at the metal plate otch is higher, which easily causes the metal plate otch to be deformed due to the high temperature, and the debris produced in the cutting process has a higher temperature equally, and the collection box 25 collects the debris When the crumbs are removed, the temperature of itself will rise, which will easily damage the inner elastic cloth pad. Refer to Figure 1-4 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the side of the lower surface of the top plate 4 away from the support plate 1 is connected with a second fixing frame 27, and the second fixing frame 27 is connected with a liquid storage tank 28 The bottom end of one side of the liquid storage tank 28 is connected with a first metal pipe 29, and one end of the first metal pipe 29 is connected with a hose 30, and the second fixed frame 27 is connected with a first connecting rod 31, an...

Embodiment 3

[0029] Because the blade 15 only needs to cool down when the metal plate is cut, and the outlet of the metal elbow 38 has been releasing coolant, resulting in waste of coolant, refer to Figure 1-4 , as another preferred embodiment of the present invention, the difference from Embodiment 2 is that the first rotating shaft 6 is connected with a first helical gear 39, the lower surface of the top plate 4 is connected with a fixed block 40, and the rotatable connection on the fixed block 40 There is a third rotating shaft 41, and the third rotating shaft 41 runs through the fixed block 40. One end of the third rotating shaft 41 is connected with a second helical gear 42, and the second helical gear 42 meshes with the first helical gear 39. The number of teeth of the first helical gear 39 is greater than The number of teeth of the second helical gear 42, the other end of the third rotating shaft 41 is connected with the third helical gear 43, the lower surface of the top plate 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com