Full-automatic light-emitting diode die bonding equipment and process

A light-emitting diode, fully automatic technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems that electromagnets cannot be sucked, separated and transported, have no transport, and the feeding device cannot be separated, etc., to improve product quality and Work efficiency, reduce the drop height, avoid the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

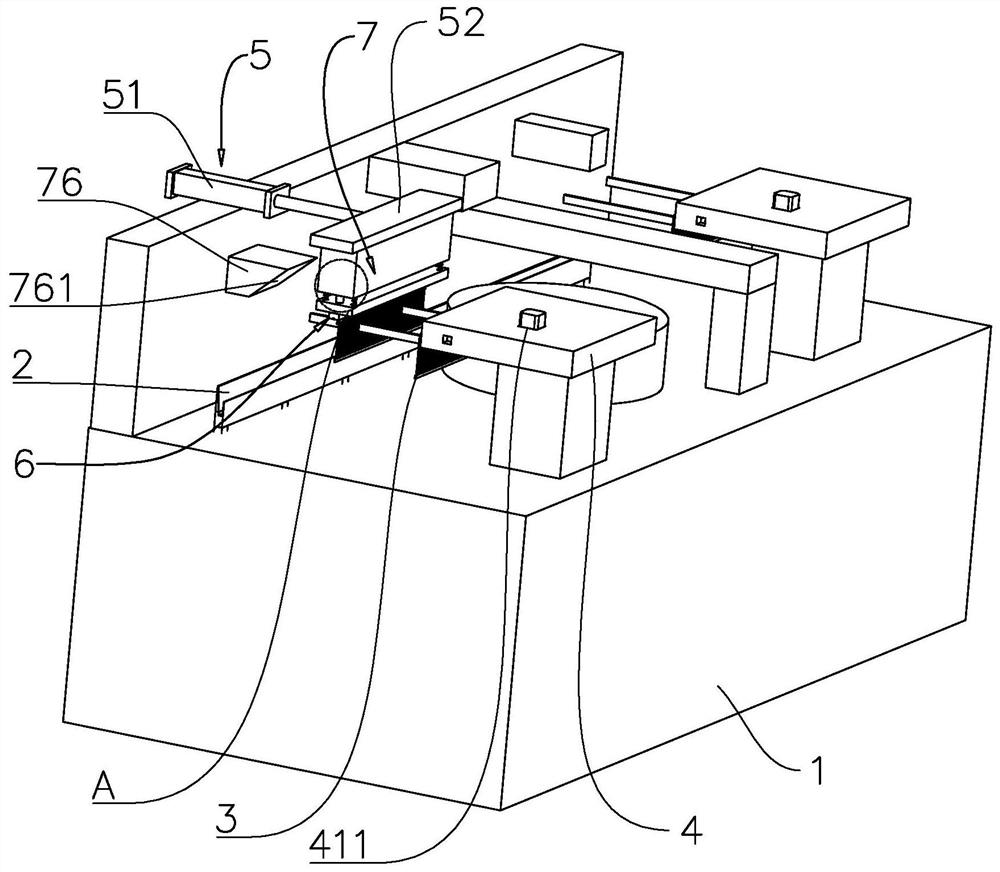

[0041] The following is attached Figure 1-5 The application is described in further detail.

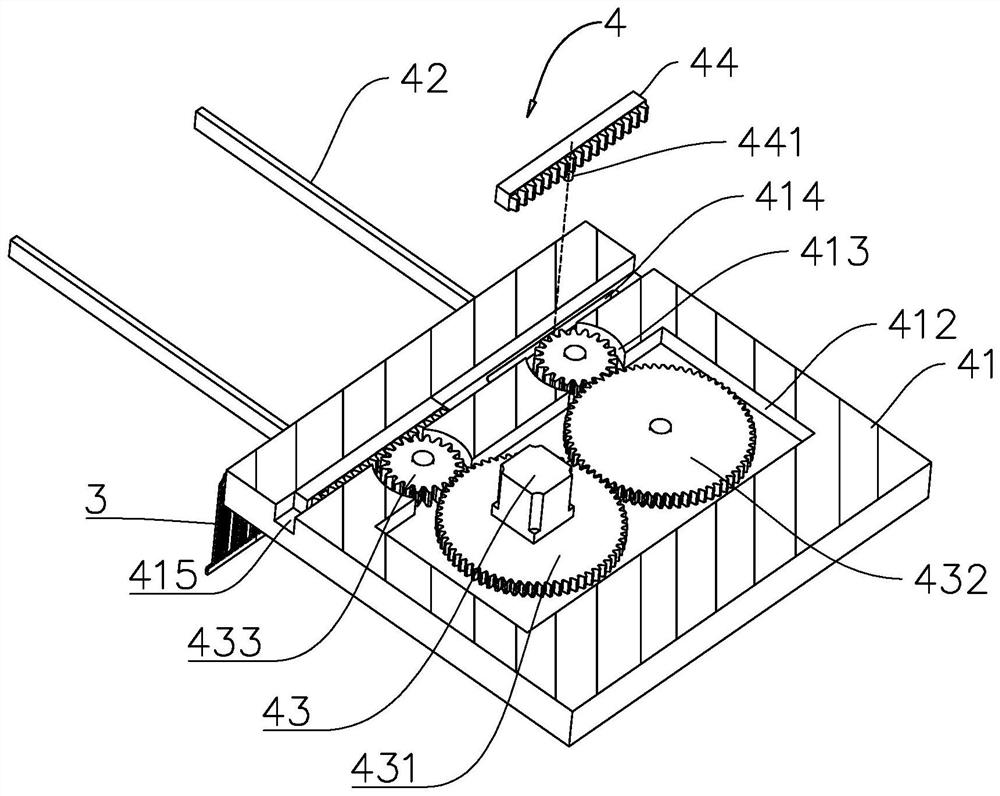

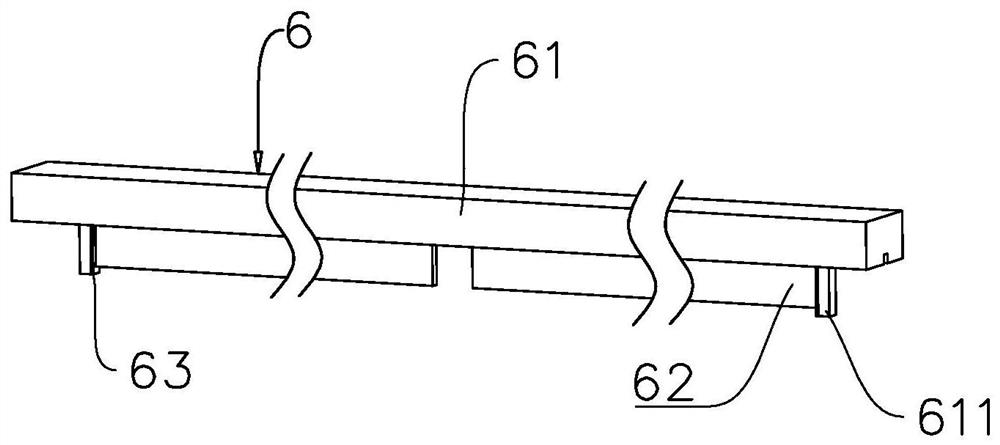

[0042] The embodiment of the present application discloses a fully automatic light-emitting diode crystal bonding equipment. refer to figure 1 and figure 2 , the fully automatic light-emitting diode crystal-bonding equipment includes a machine base 1, the machine base 1 is vertically arranged, the upper end of the machine base 1 is provided with a flow channel 2, and one side of the flow channel 2 is provided with a material fork 4 for placing several brackets 3, and the material The fork 4 includes a chassis 41 and two parallel supporting rods 42 arranged on the chassis 41, wherein the chassis 41 is horizontally arranged and installed on the upper end surface of the machine base 1, and the supporting rods 42 are located on the side of the chassis 41 close to the flow channel 2 , the two supporting rods 42 pass through the bracket 3 so that the bracket 3 overlaps the two supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com