Textile cloth cutting device

A cutting device and textile cloth technology, applied in the field of textile cloth processing, can solve the problems of not being able to adapt to different materials and different specifications, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

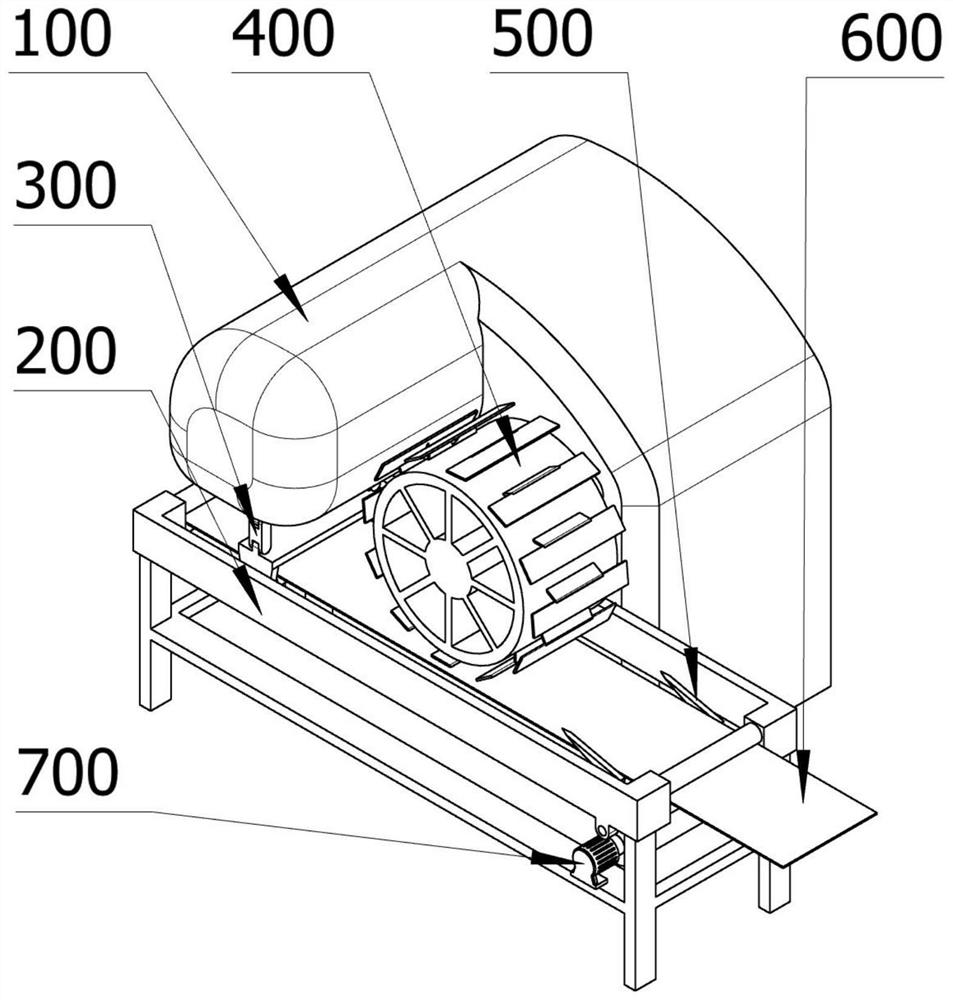

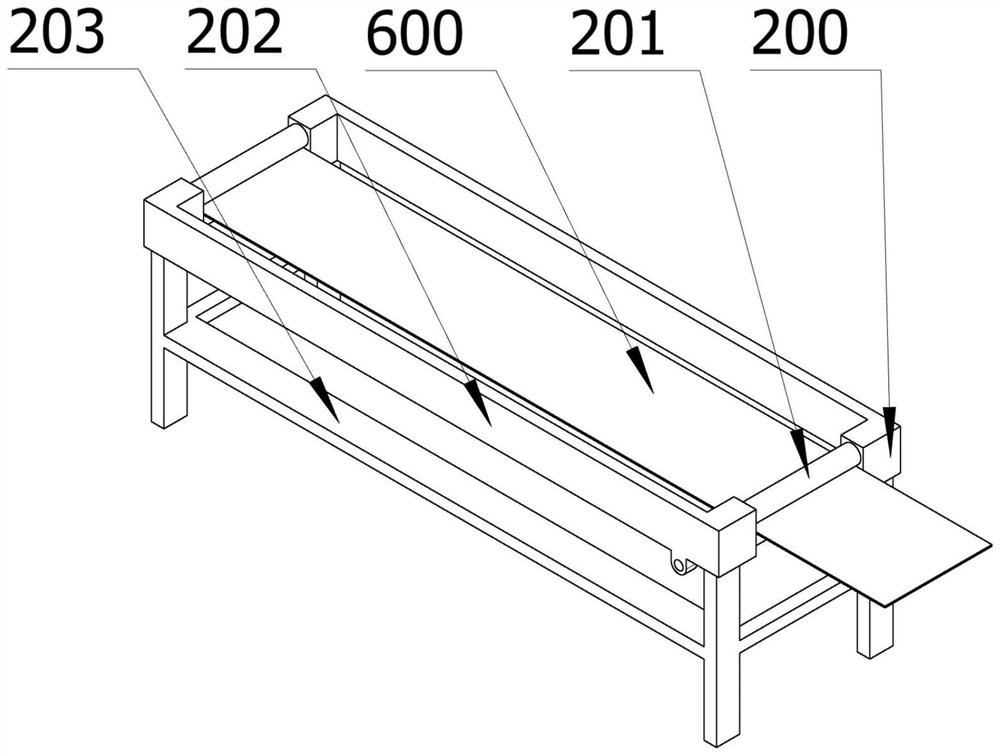

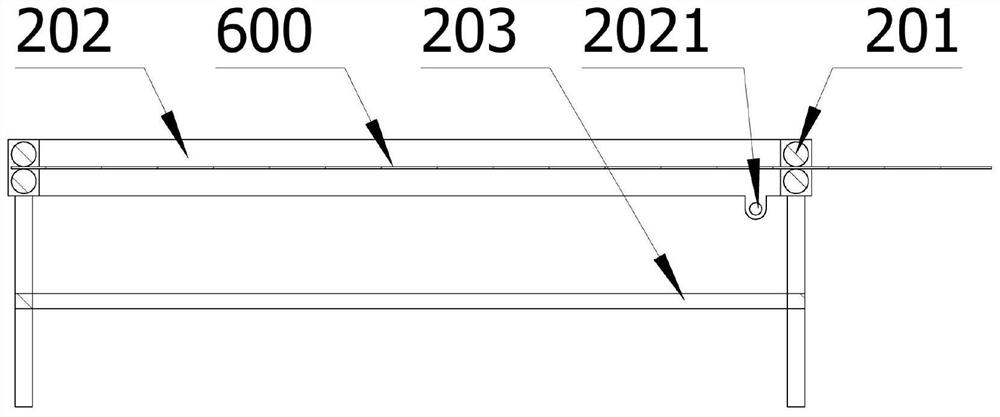

[0066] Such as figure 1 — image 3 As shown, a textile cloth cutting device includes: a textile cloth cutting device, including: a driving part 100 , a transport part 200 , a first adjustment part 300 , a second adjustment part 400 , and a cutting part 500 . There is accommodating space in the driving part 100, and the driving part 100 is used to drive the textile cloth cutting device; the transportation part 200 is arranged on one side of the driving part 100, and the transportation part 200 is used to transport the textile cloth 600 to be cut, and the transportation part 200 has: Roller 201, conveying roller 201 has multiple, conveying roller 201 is arranged on the two ends of conveying part 200, and conveying roller 201 is used for conveying the textile cloth 600 that needs cutting; The upper end of the adjustment part 300 protrudes into the accommodation space of the driving part 100, the first adjustment part 300 is used to adjust the position of the textile cloth 600 to...

Embodiment 2

[0083] A method for cutting textile cloth, comprising the steps of:

[0084] Transport, the textile cloth 600 is transported from the transport department 200, and transported between a plurality of transport rollers 201;

[0085] For the first adjustment, the driving part 100 is driven, and the driving part 100 is driven to drive the second bevel gear 307 to rotate, thereby driving the first bevel gear 306 to rotate, thereby driving the rotating disk 305 to rotate, thereby driving the first bevel gear 307 to rotate. The adjustment unit 300 performs the first adjustment;

[0086] For the second adjustment, the drive unit 100 continues to drive, and the drive unit 100 drives to drive the drive shaft 401 to rotate, thereby driving the second adjustment unit 400 to perform the second adjustment;

[0087] For cutting, the woven fabric 600 is transported to the cutting section 500 for cutting.

[0088] Further, for the first adjustment, the following steps are also included: when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com