Production process of high-wear-resistance cotton elastic fabric

A production process, wear-resistant cotton elastic technology, applied in the direction of wear-resistant fiber, biochemical fiber treatment, textile material treatment, etc., can solve the problems of poor tear resistance, reduced fiber strength, poor tear resistance, etc. , to achieve the effects of avoiding whitening inside the yarn, improving tear strength, super wear resistance and drape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1. The production process of high wear-resistant cotton elastic fabric comprises the following steps:

[0036] A, the cotton-elastic fabric is subjected to cold-stack rolling enzyme treatment to obtain product A;

[0037] B. To stack A product, the time is 12-14h, the temperature is 30-40 ℃, and B product is obtained;

[0038] C. Rinse product B to obtain product C;

[0039] D. Carry out singeing treatment to product C to obtain product D;

[0040] E, do mercerizing treatment to product D to obtain product E;

[0041] F, do cold stack dyeing process to E product, obtain F product;

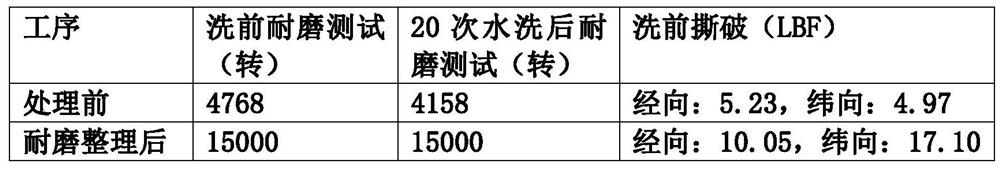

[0042] G. Carry out wear-resisting finishing on product F to obtain product G;

[0043] H, roasting product G to obtain product H;

[0044] I. Pre-shrink the H product to obtain the finished product of high wear-resistant cotton elastic fabric;

[0045] During the wear-resistant treatment, the product F is impregnated with a wear-resistant treatment solution, and the temperatu...

Embodiment 2

[0062] Example 2. The production process of high wear-resistant cotton elastic fabric comprises the following steps:

[0063] A, the cotton-elastic fabric is subjected to cold-stack rolling enzyme treatment to obtain product A;

[0064] B. The product A is stacked for 14 hours at a temperature of 40° C. to obtain product B;

[0065] C. Rinse product B to obtain product C;

[0066] D. Carry out singeing treatment to product C to obtain product D;

[0067] E, do mercerizing treatment to product D to obtain product E;

[0068] F, do cold stack dyeing process to E product, obtain F product;

[0069] G. Carry out wear-resisting finishing on product F to obtain product G;

[0070] H, roasting product G to obtain product H;

[0071] I. Pre-shrink the H product to obtain the finished product of high wear-resistant cotton elastic fabric;

[0072] During the wear-resistant treatment, the product F is impregnated with a wear-resistant treatment solution, and the temperature of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com