Buoyancy water lifting equipment for water conservancy and hydropower

A technology of water conservancy, hydropower and buoyancy, which is applied in the direction of mechanical equipment, hydroelectric power generation, cleaning methods using tools, etc., can solve problems affecting water lifting efficiency, sliding wall corrosion, scale formation, etc., and achieve the effect of avoiding internal water backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

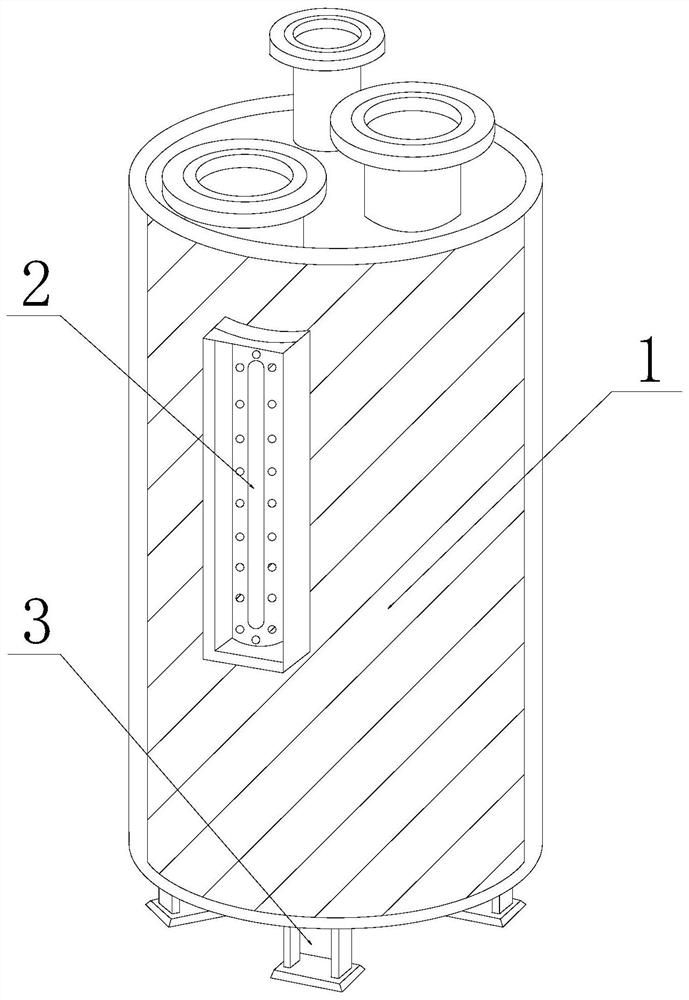

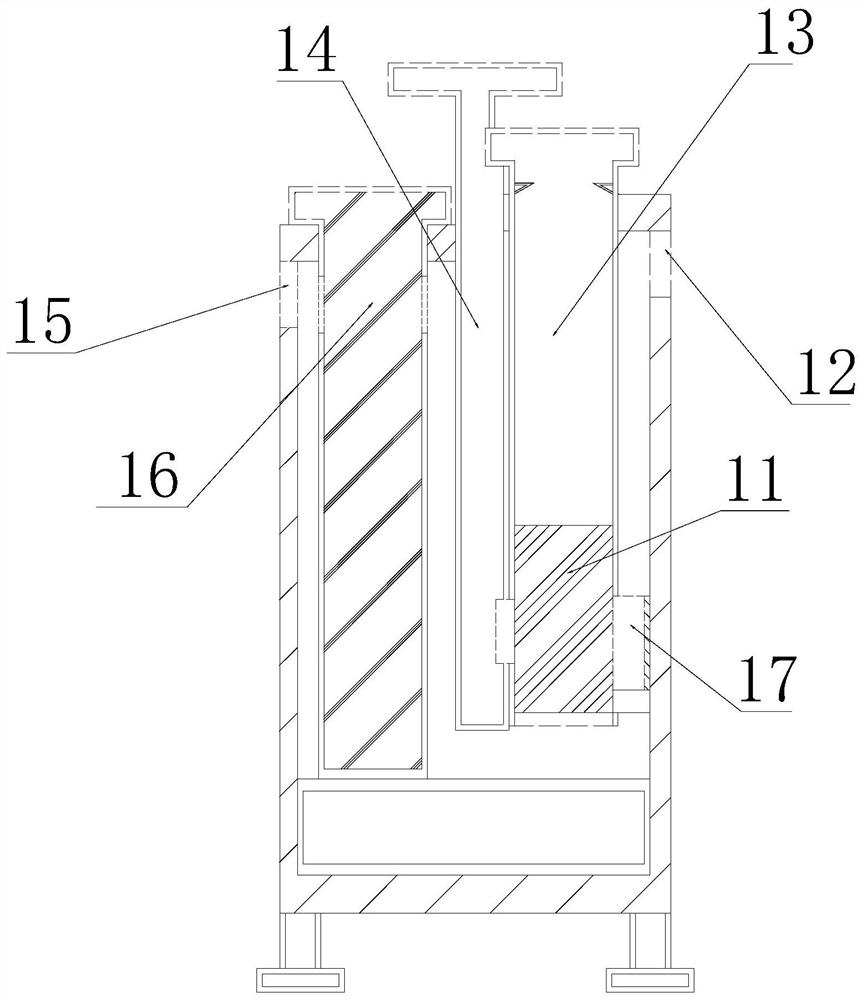

[0026] as attached figure 1 to attach Figure 5 Shown:

[0027] Its structure includes a container tank 1, an observation table 2, and a support base 3. The observation table 2 is nested and connected with the inside of the container tank 1, and the support base 3 is welded with the bottom end of the container tank 1. The inside of the container tank 1 includes Control valve 11, drainage hole 12, water outlet pipe 13, air pressure pipe 14, water inlet hole 15, water inlet pipe 16, air tank 17, the control valve 11 is nested and connected with the water outlet pipe 13, and the bottom of the water outlet pipe 13 is connected with the air The two walls of the groove 17 are engaged and connected, and the air pressure pipe 14 is fixed on the right side of the water inlet pipe 16 to coordinate with its activities. The wall is movably matched, and the control valve 11 is movably matched with the right wall of the air pressure pipe 14 .

[0028] Wherein, the control valve 11 includ...

Embodiment 2

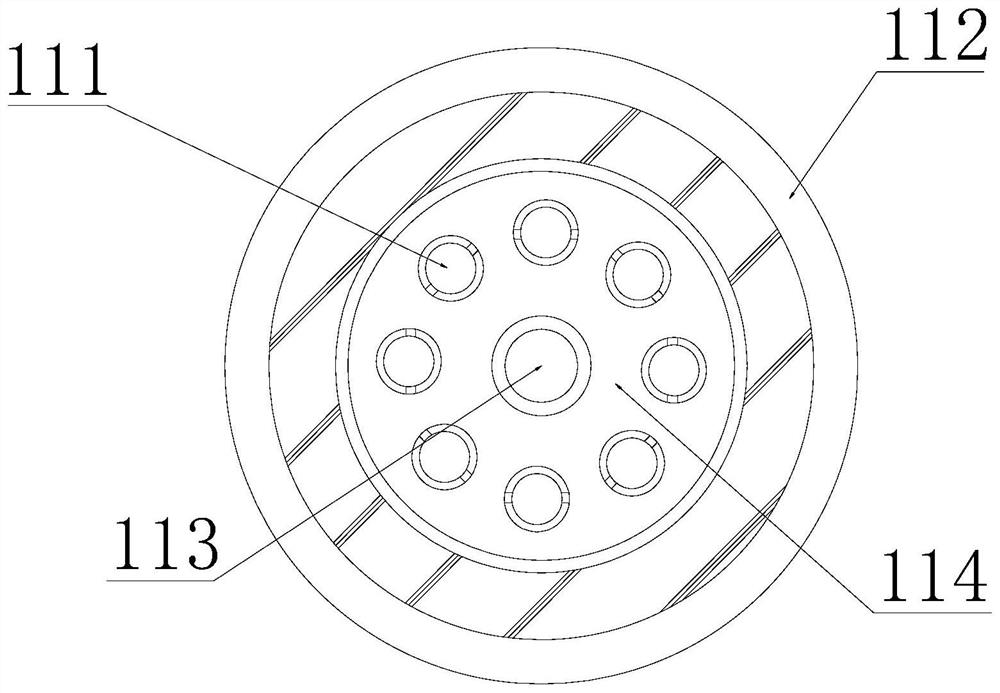

[0034] as attached Figure 6 to attach Figure 7 Shown:

[0035]Wherein, the one-way valve 111 includes a valve piece b1, a sleeve b2, and a valve body b3, the sleeve b2 is fixed on the left and right sides of the valve body b3, and is embedded and connected with it, and the two walls of the valve piece b1 are connected with the sleeve The inside of b2 is snapped and connected, the valve piece b1 is nested inside the valve body b3, and fits with its clearance, and the sleeve b2 is provided with two, which are distributed at the left and right ends of the valve body b3 and are embedded and connected with it, wherein the valve piece b1 It is beneficial to open and close through the impact of water flow, so that the water flow can pass through its valve effectively.

[0036] Wherein, the inside of the valve body b3 includes a rotating rod b31, a spring clamp b32, a blocking plate b33, and a concave buckle b34. The inside of the buckle b34 is snapped and connected, the barrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com