Hydraulic fan system and engineering machinery

A fan system, hydraulic technology, applied in the direction of fluid pressure actuation system components, mechanical equipment, machines/engines, etc., can solve the problem that the hydraulic fan system cannot automatically reverse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

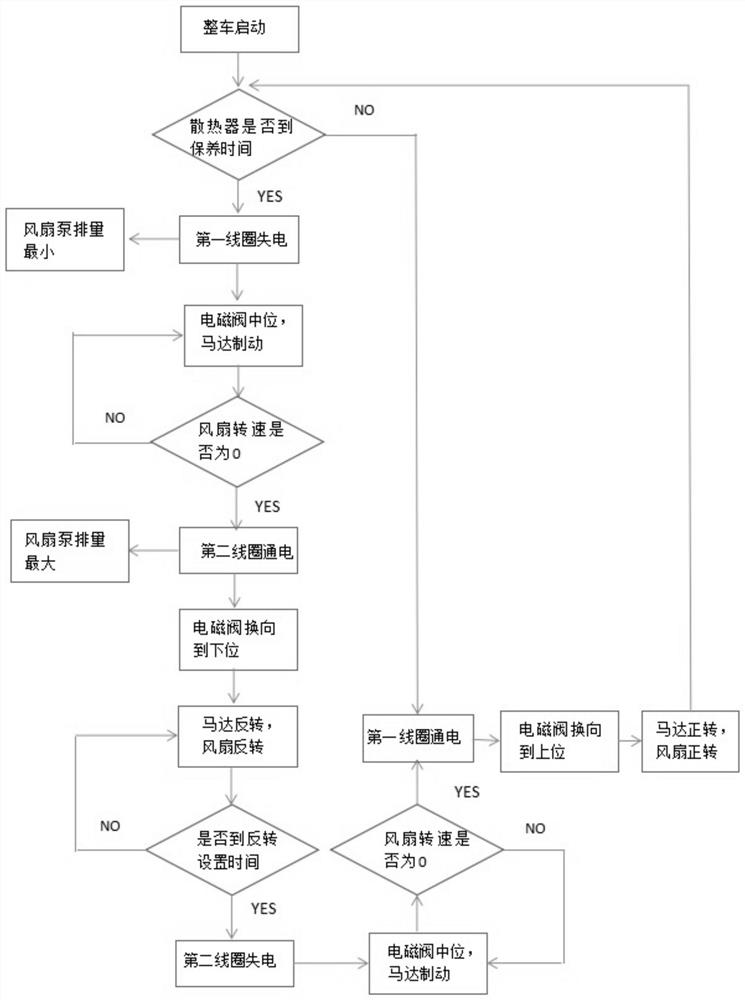

[0016]The specific implementation scheme is described below in conjunction with the drawings.

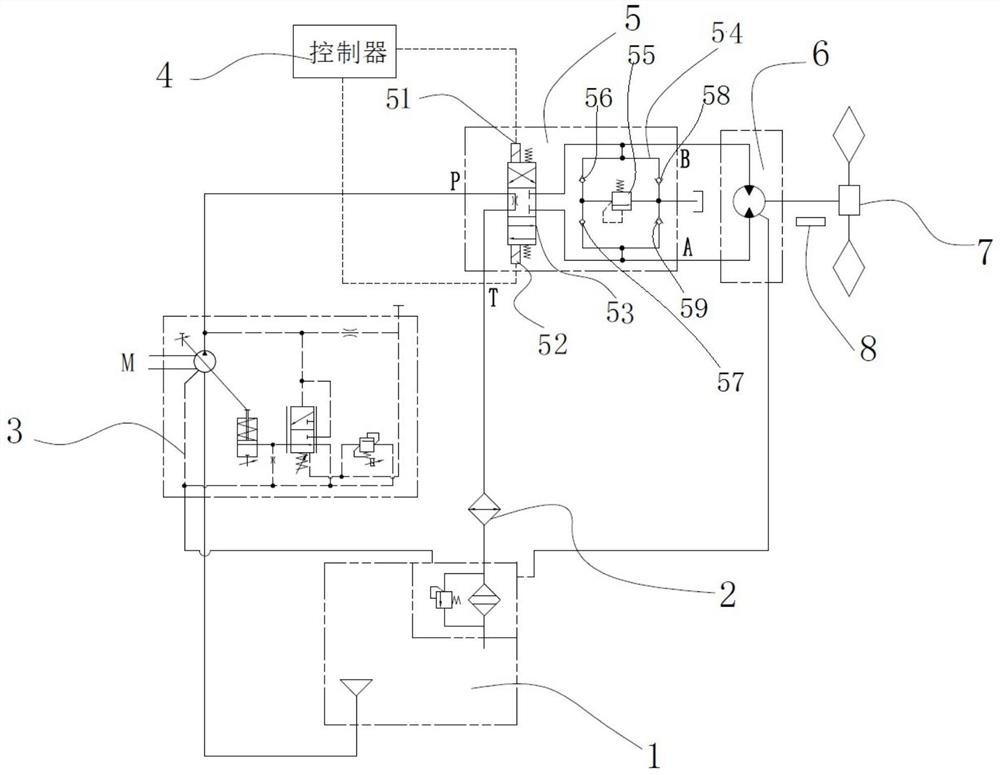

[0017]figure 1 Shows a hydraulic fan system used in construction machinery. The system is used in conjunction with the radiator of the construction machinery to drive cold air to flow through the radiator to improve the heat dissipation efficiency of the radiator. In this embodiment, the hydraulic fan system includes a hydraulic oil tank, a fan pump connected to the hydraulic oil tank at the oil inlet, a control valve, a fan motor, a controller, and a speed sensor for detecting the speed of the fan pump and connected to the controller. .

[0018]The fan pump is a variable displacement plunger pump. By controlling the displacement of the fan pump, the fan speed can be controlled.

[0019]The control valve includes an electromagnetic reversing valve 53 and a motor brake circuit 54. The electromagnetic reversing valve 53 is an M-type neutral three-position four-way reversing valve and the PT center i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com