Rapid capsule drying machine

A rapid drying and capsule technology, which is applied in the direction of dryers, drying, local stirring dryers, etc., can solve the problems of insufficient drying, adhesion, and long drying time, so as to prevent high-temperature melting, increase safety, and dry high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

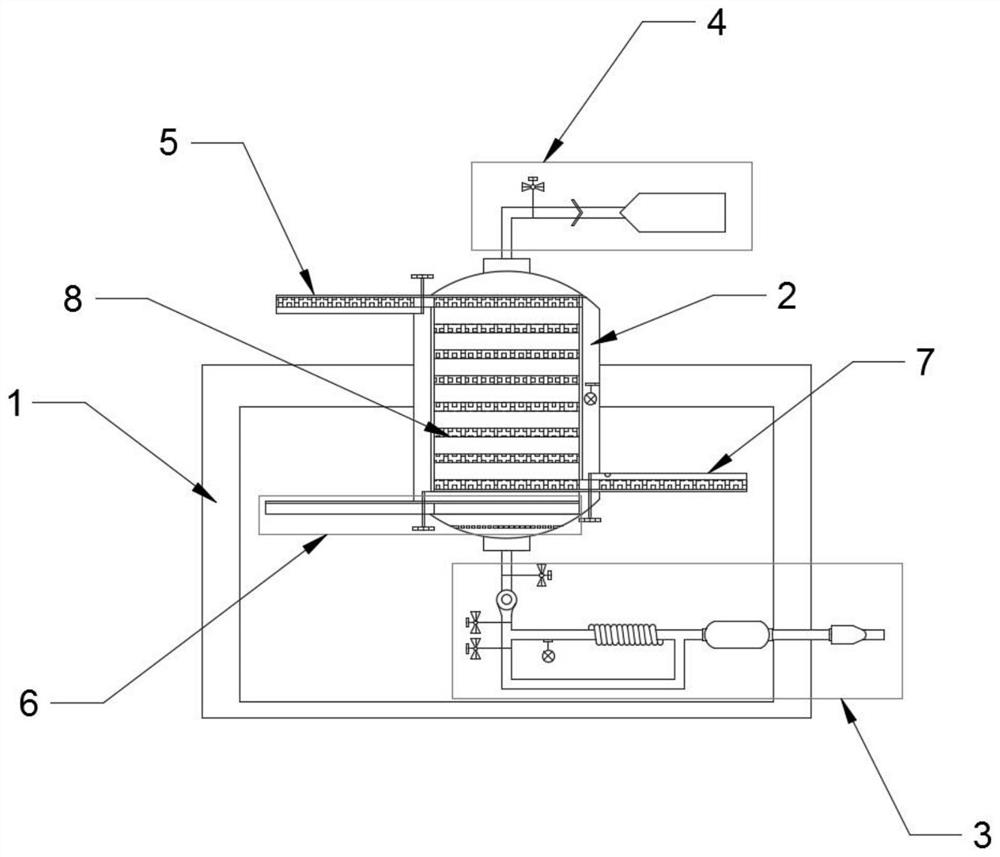

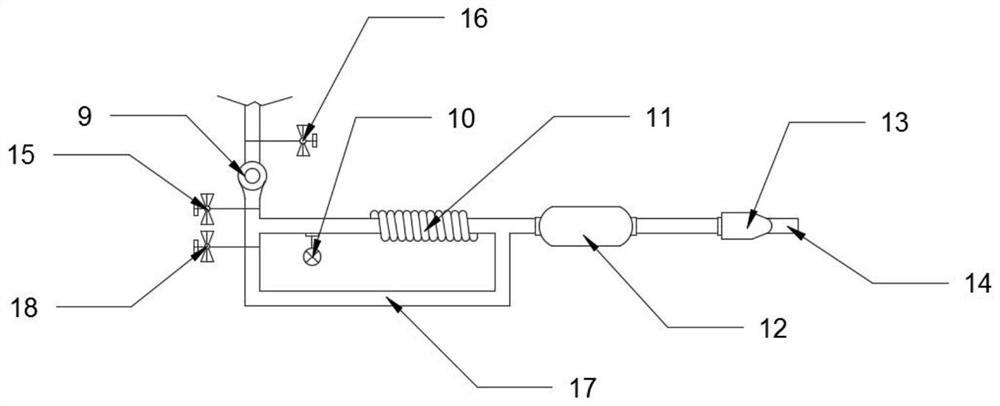

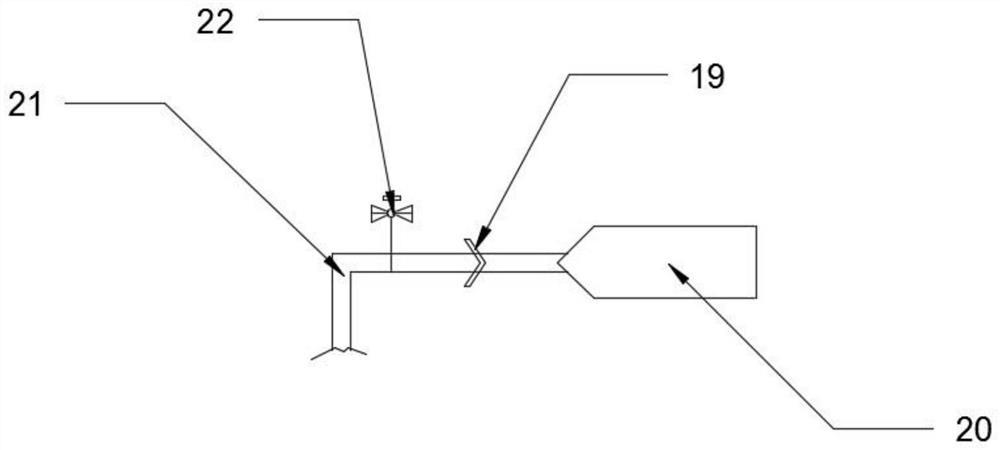

[0033] Example: see figure 1 , in the present invention, the quick drying machine for capsules includes a support frame 1, the support frame 1 is used to support the drying cylinder 2, the support frame 1 is provided with a drying cylinder 2, and the drying cylinder 2 is a hollow cylindrical structure, which is The place where the capsules are dried, the lower end of the drying cylinder 2 is equipped with a quick air intake device 3, the quick air intake device 3 quickly heats up and dries the air and then cools it down to about 45°C, and then accelerates the processed air and fills it into the drying cylinder 2, the upper end of the drying cylinder 2 is provided with an exhaust device 4, and the upper end of one side of the drying cylinder 2 is provided with a material inlet 5, and the material inlet 5 can pass through the material holding plate 8, and the capsules can be placed in the material holding plate 8 , can be sent into the drying cylinder 2 through the guide rail, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com