Wiper system installation method based on EMU wiper installation inspection device

A technology for inspection device and system installation, which is applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve problems such as the deviation of the center position of the brush arm, the jitter of the brush arm, and the inability to achieve dynamic data matching, and achieve improved installation. Process, reduce labor intensity, improve adjustment efficiency and the effect of quality data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

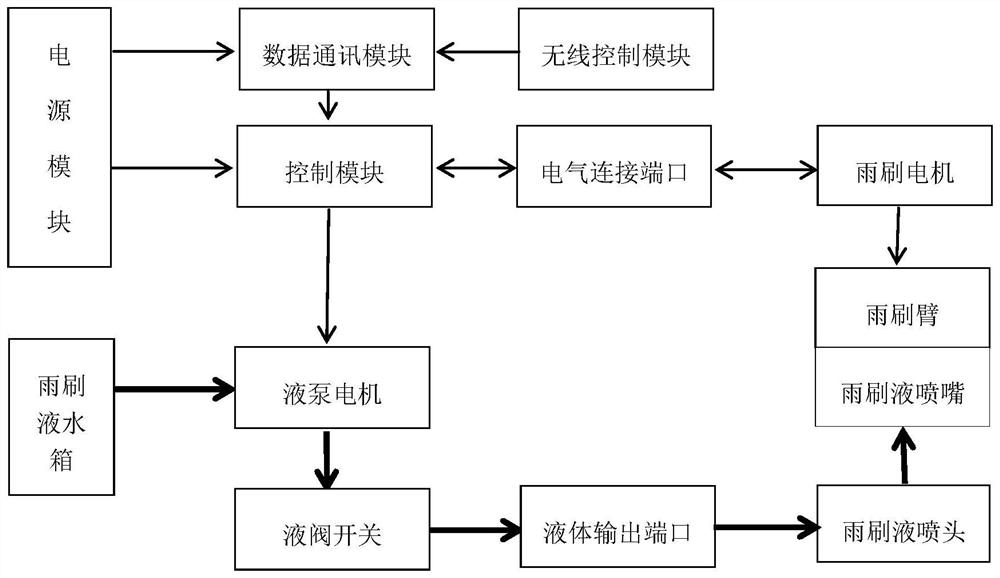

[0019] Specific implementation mode 1. Combination figure 1 Describe this embodiment, a kind of EMU wiper installation inspection device, the EMU wiper installation inspection device is composed of a power module, a control module, a data communication module, a wireless controller, an electrical connection port, a wiper fluid tank, a liquid pump motor, and a liquid valve Switches, liquid output ports, etc.; the electrical part is connected to the control module and the data communication module to provide power for the electrical part. The wireless controller sends various working condition control instructions to the control module through the data communication module. The connection port outputs power of different standards to the wiper motor and collects the feedback signal of the wiper motor to form precise control, controls the wiper motor mechanism to drive the wiper arm to complete the stroke and swing speed under different working conditions, and the control module ou...

specific Embodiment approach 2

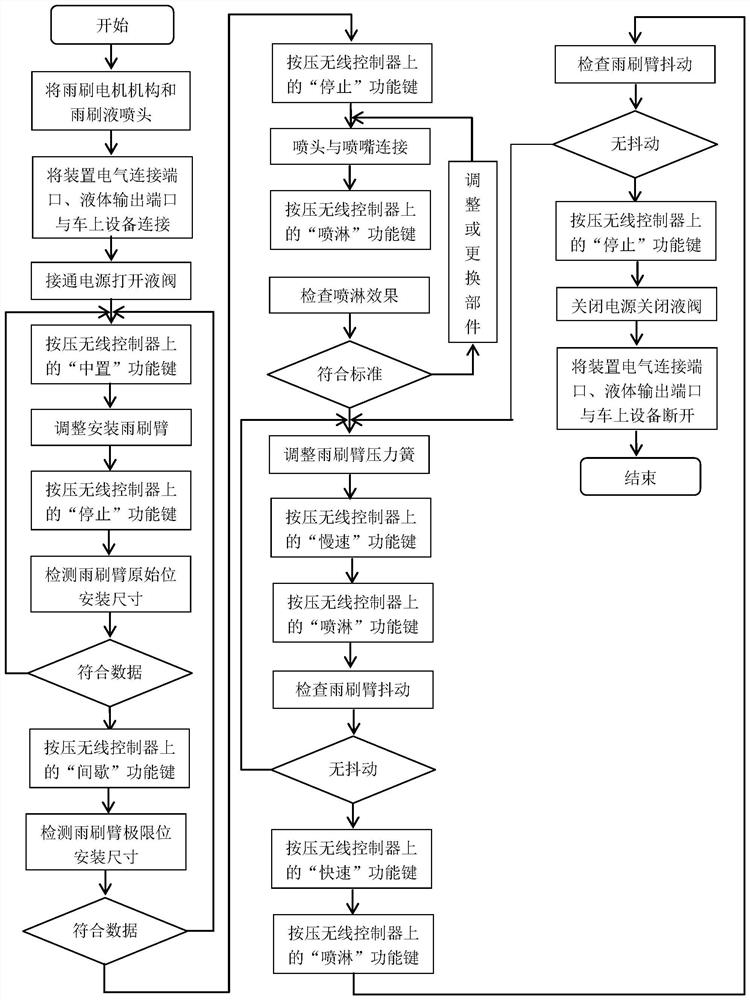

[0020] Specific embodiment two, combine figure 2 Describe this embodiment, the wiper system installation method based on EMU wiper installation inspection device, this method is realized by the following steps:

[0021] 1. Fix the wiper motor mechanism (integrated frame with wiper motor and wiper arm transmission mechanism) and the wiper fluid nozzle on the steel structure of the EMU car body, and then place the EMU wiper installation inspection device inside the EMU vehicle. The electrical connection port is connected to the wiper motor, the liquid output port is connected to the input end of the wiper fluid nozzle, the system power supply is turned on, the liquid valve switch is turned on, and the vehicle goes to the working area outside the vehicle.

[0022] 2. Press the "center" function key on the wireless controller, and the data communication module decodes and transmits the control module to control the wiper motor mechanism to run to the specified angle through the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com