Cooling tower filler performance experiment detection system

A detection system and cooling tower technology, applied in water shower coolers, material thermal development, direct contact heat exchangers, etc., can solve the problems of large fluctuations and large errors in evaluation and test results, and reduce errors and time, guarantee test accuracy, and widen the effect of time range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

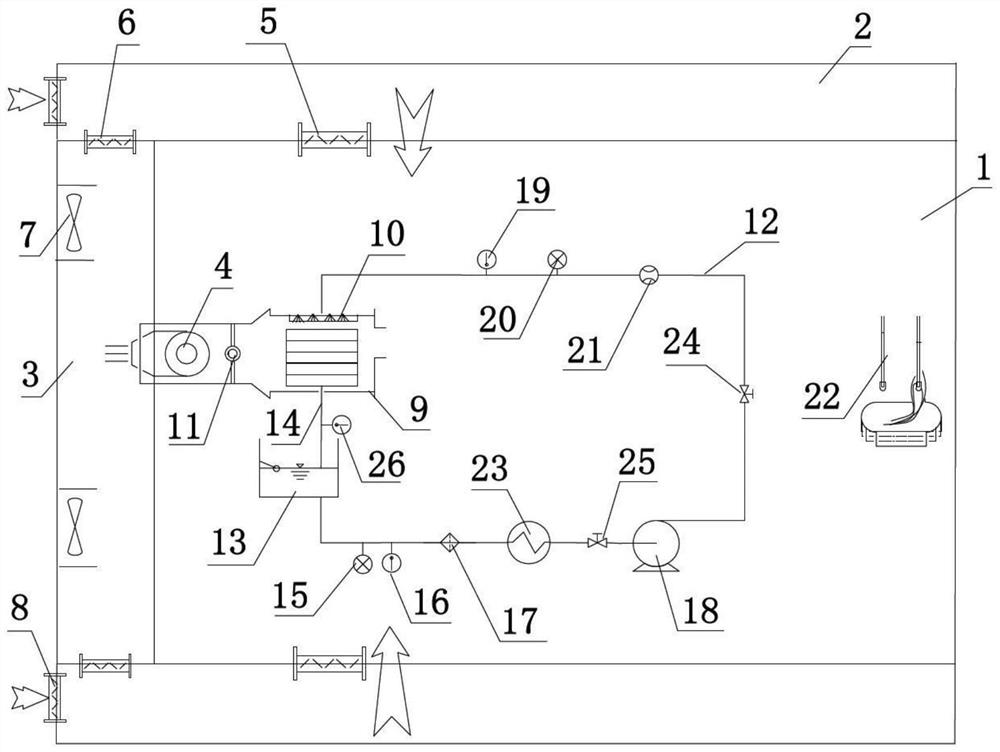

[0015] Attached below figure 1 The present invention is described further:

[0016] An experimental detection system for cooling tower packing performance, comprising an air mixing area 2 and an exhaust area 3 arranged outside the packing performance testing laboratory 1, and a frequency conversion fan a4 is arranged between the packing performance testing laboratory 1 and the exhaust area 3, There is an electric louver a5 between the filler performance testing laboratory 1 and the air mixing area 2, an electric louver b6 between the air mixing area 2 and the exhaust area 3, and two symmetrical air outlets in the exhaust area 3. The air outlet is provided with a frequency conversion fan b7, and the two frequency conversion fans b7 are located on both sides of the frequency conversion fan a4, and an electric shutter c8 is provided at the air inlet of the air mixing area 2, and the packing performance testing laboratory 1 is equipped with The filler placement frame 9 located at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com