Measuring cell and assembly having at least one measuring cell for measuring the conductivity and/or impedance of milk during a milking process

A technology of measuring units and measuring devices, applied in the direction of milking devices, applications, material resistance, etc., capable of solving problems such as air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

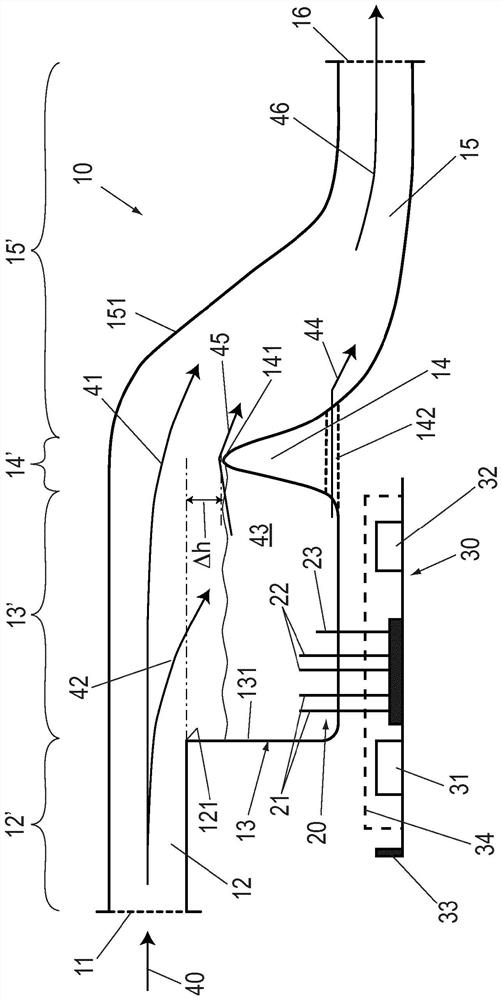

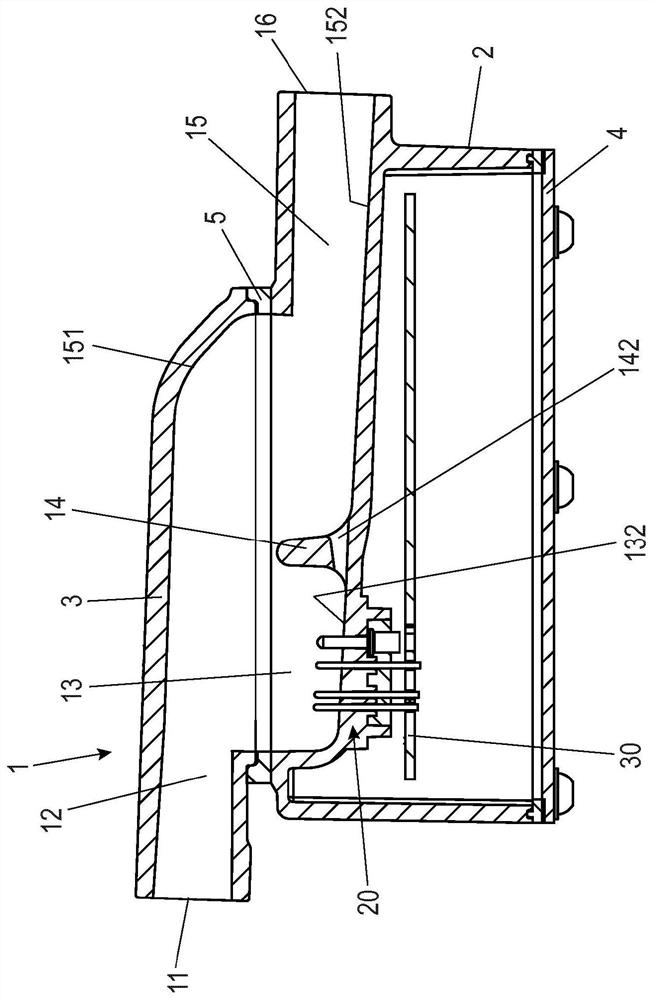

[0027] figure 1 An exemplary embodiment of a measuring unit 10 for conducting conductivity and impedance measurements during a milking process is shown in a schematic cross-section.

[0028]The measuring unit 10 has an inlet 11 for incoming milk and an outlet 16 on the opposite side of the housing of the measuring unit 10 . In an installation position which essentially corresponds to the orientation shown in the figure, the outlet 16 is positioned deeper than the inlet 11 . Between the inlet 11 and the outlet 16, the measuring cell 10 can be divided into four different sections: an inlet section 12' with an inlet channel 12 connected to the inlet 11, a measuring section 13' with a measuring groove 13, Barrier section 14 ′ with barrier 14 and outlet section 15 ′ with outlet channel 15 opening into outlet 16 . The measuring unit 10 is divided into different sections 12' to 15' in figure 1 shown at the upper edge of .

[0029] The inlet channel 12 is connected to the inlet 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com