A kind of intelligent bacterium cultivation process and its equipment

An intelligent and technological technology, applied in the field of intelligent bacteria raising technology and its equipment, can solve the problems of heavy workload, unsatisfactory, unstable and other problems, and achieve the effect of ensuring normal growth, guaranteeing output and reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

[0029] With reference to accompanying drawing: a kind of intelligent bacterium cultivation technology in the present embodiment, comprises the following steps:

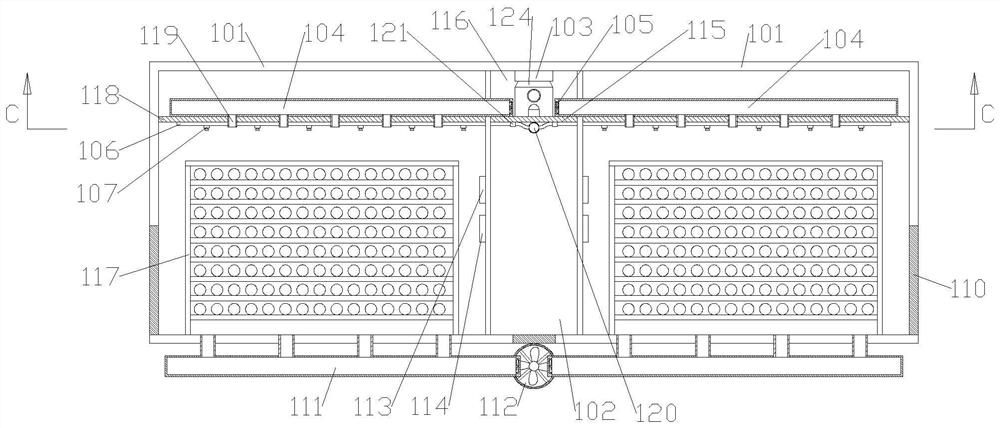

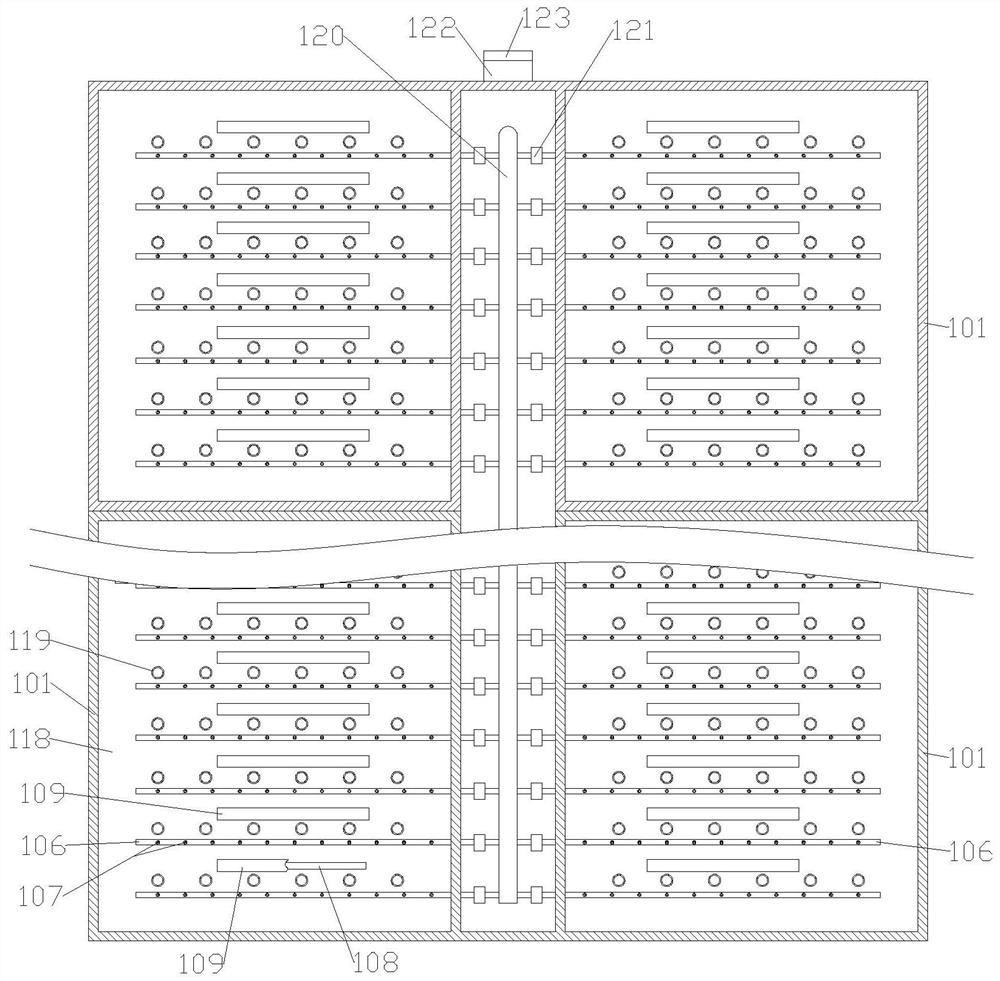

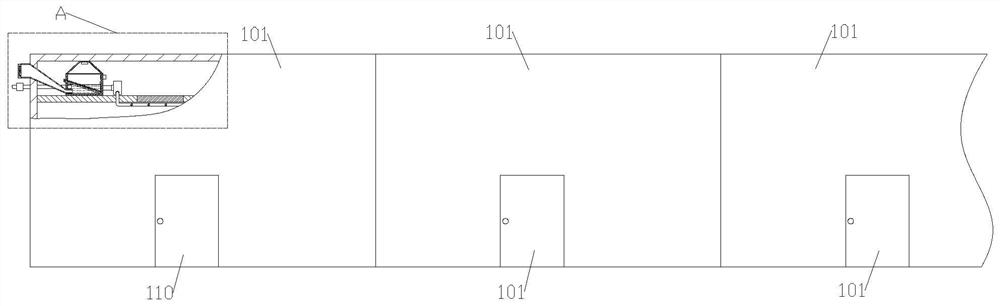

[0030] A1 Build bacteria culture room: build several interconnected bacteria culture rooms 101 on the left and right sides of the flat ground, and a connection channel 102 is built between the bacteria culture rooms 101 on the left and right sides, and the upper end of the connection channel 102 is separated by a partition plate 115 There is a ventilation channel 116, and the inside of the ventilation channel 116 is equipped with an adjustable air conditioner 103; several evenly distributed placement racks 117 are arranged in the bacteria cultivation room 101; the top of the bacteria cultivation room 101 is fixedly connected with a second partition plate 118, the upper end of the second partition plate 118 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com