Rice milling device for rice processing

A technology of rice processing and rolling rollers, which is applied in the fields of application, grain finishing, and grain germ removal, which can solve the problems of increasing the risk of broken rice and achieve the effect of reducing the phenomenon of broken rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

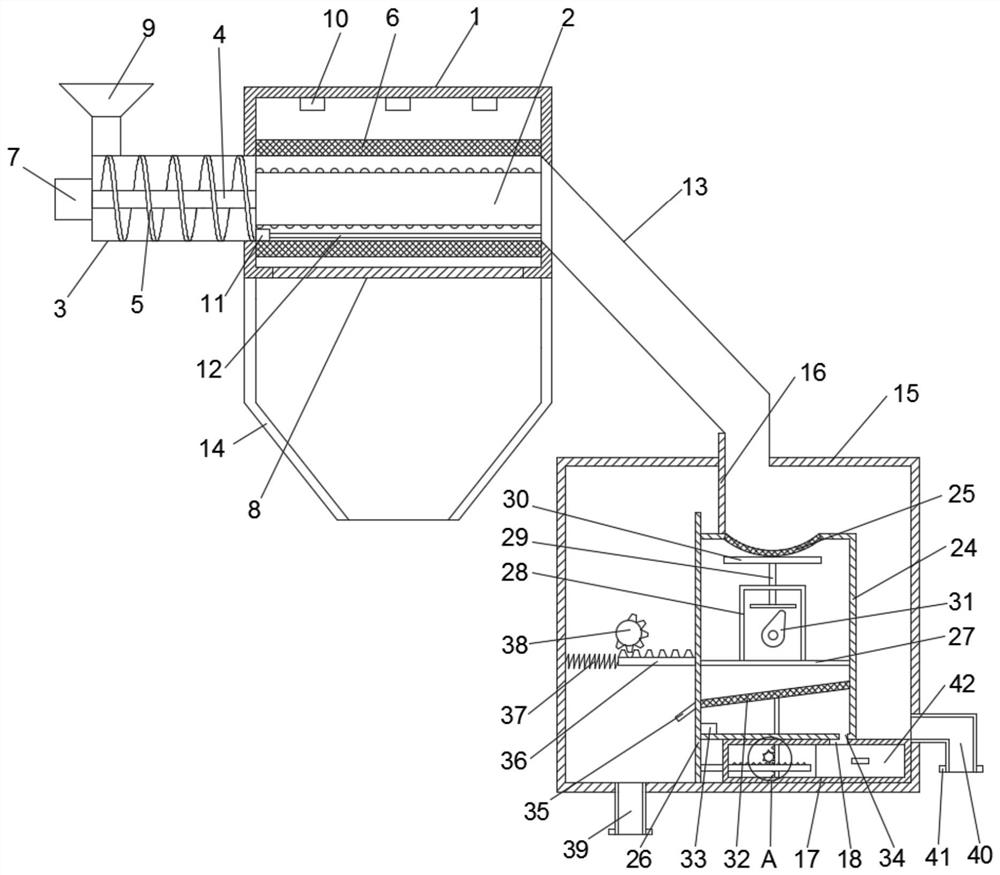

[0030] Embodiment 1: as figure 1 As shown, a rice milling device for rice processing includes a rice milling box 1, the middle part of the rice milling box 1 is rotatably equipped with a rolling roller 2, and the top of the rice milling box 1 is provided with several groups of first air blowers 10, so The left side of the rice milling box 1 is fixedly equipped with a delivery box 3, and the middle part of the delivery box 3 is fixedly equipped with a transmission shaft 4. The transmission shaft 4 is fixedly connected with the rolling roller 2 and is a concentric structure. A helical blade 5 is fixedly installed; a rice bucket 9 is fixedly installed on the top left side of the delivery box 3, and the interior of the delivery box 3 communicates with the rice milling box 1, and a motor 7 is fixedly installed on the left side of the delivery box 3. The output shaft of the motor 7 is fixedly connected with the transmission shaft 4; the rice is put into the feed hopper 9, the motor ...

Embodiment 2

[0034] Embodiment 2: as Figure 2-4 As shown, on the basis of Embodiment 1, the bottom of the moving box 24 is provided with a discharge port 34, the middle part of the moving box 24 is fixedly equipped with a support plate 27, and the upper side of the support plate 27 is fixedly equipped with a closed box 28, The middle part of the closed box 28 is rotatably equipped with a cam 31, the cam 31 is driven by a rotating motor, the top of the closed box 28 is slidably mounted with a T-shaped bar 29, the bottom of the T-shaped bar 29 is in movable contact with the cam 31, and the T-shaped bar 29 is in movable contact with the cam 31. A top plate 30 is fixedly installed on the top of the rod 29, and the top plate 30 is in movable contact with the first filter screen 25; by controlling the rotation of the rotating motor to drive the cam 31 to rotate counterclockwise, the T-shaped bar 29 and the top plate 30 are pushed upward, so that the first filter screen 25 and mobile case 24 upp...

Embodiment 3

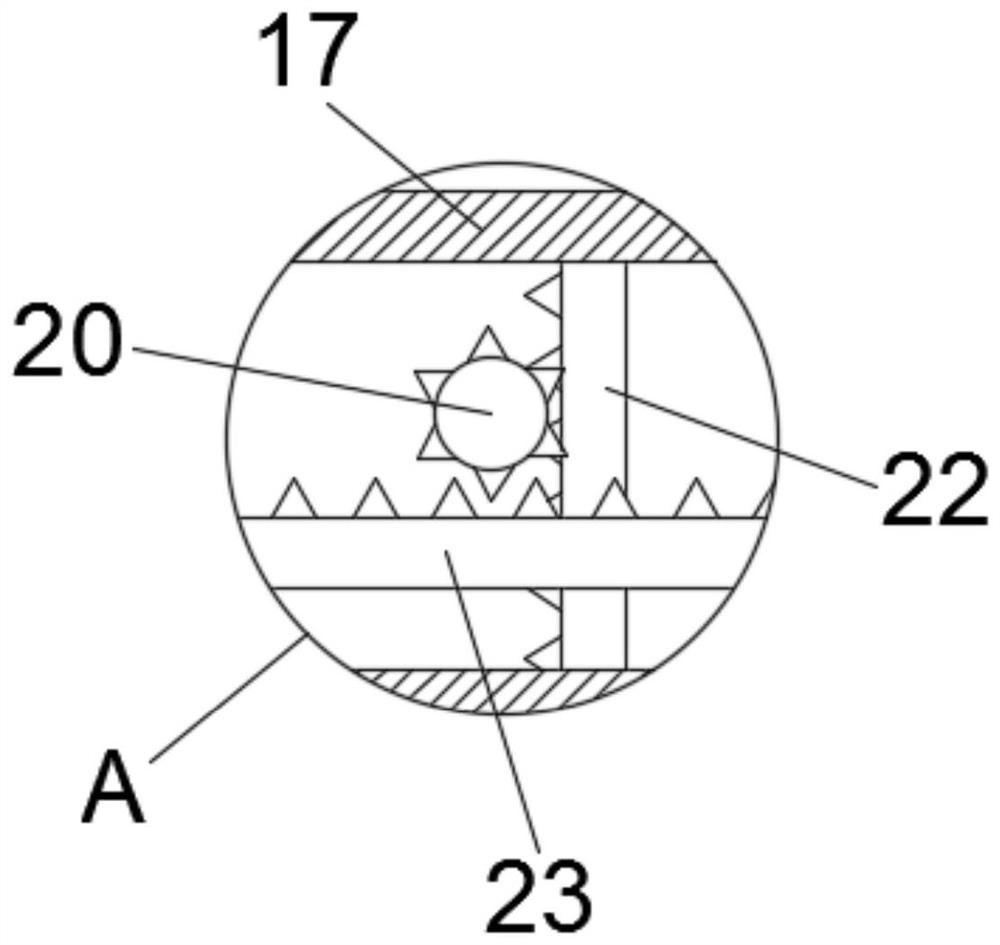

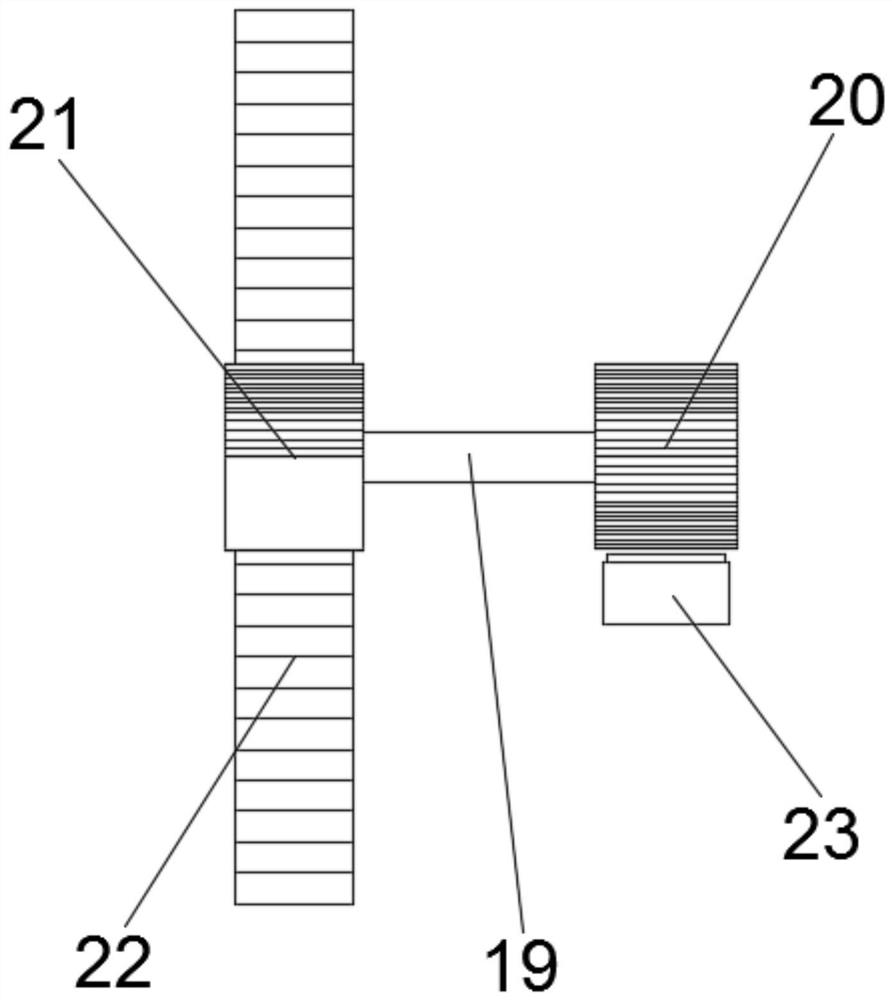

[0036] Embodiment 3: On the basis of Embodiment 1 and Embodiment 2, a second filter screen 32 is fixedly installed at the bottom of the mobile box 24, and the second filter screen 32 is arranged obliquely, and the bottom of the second filter screen 32 is fixedly installed There is a first tooth plate 22, the first tooth plate 22 runs through the moving box 24 and the fixed box 17, the meshing connection between the first tooth plate 22 and the first half gear 21, and the second filter screen 32 is flexible filter screen, the bottom of the moving box 24 is provided with a second blower 33 , and the left side of the moving box 24 is provided with a material guide plate 35 , and the material guide plate 35 is located at the lower side of the second filter screen 32 . The top of the fixed box 17 is provided with a waste port 18, and a rotating shaft 19 is installed between the front and rear side walls on the left side of the fixed box 17. One end of the rotating shaft 19 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com