Portable omni-directional professional straightening and correcting tool

An all-round and portable technology, applied in the field of calibration and alignment, can solve the problems of alignment, calibration, time-consuming and labor-intensive use, and hidden dangers in use, so as to save costs and increase practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

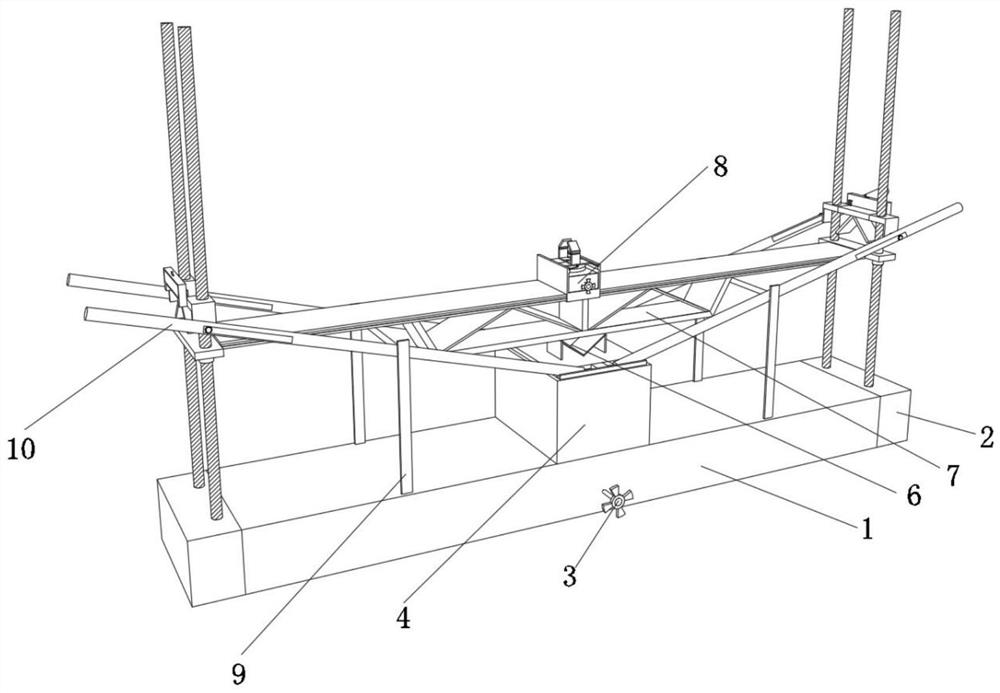

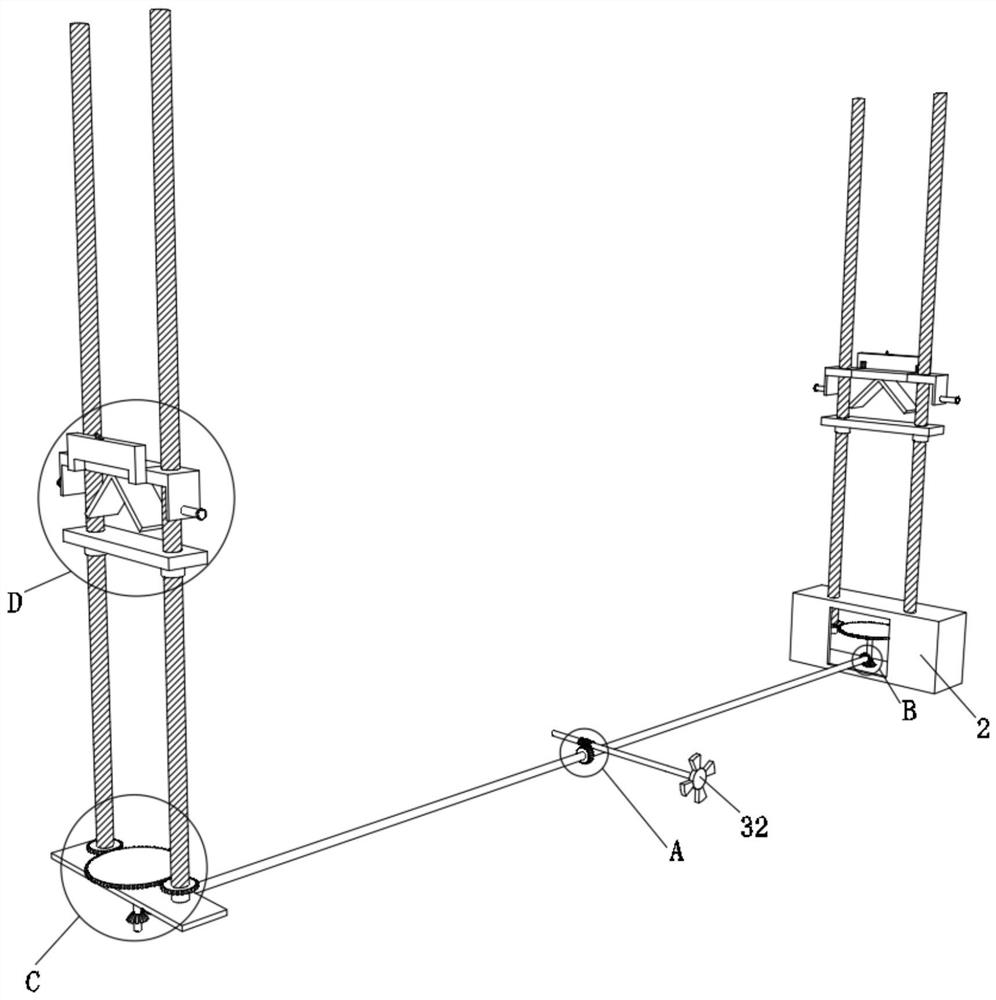

[0033] The portable all-round professional straightening and correction tool of the preferred embodiment of the present invention, such as Figure 1-Figure 8 As shown, including the load-bearing beam 1, the two ends of the load-bearing beam 1 are welded with a base 2, the inside of the load-bearing beam 1 is provided with a transmission mechanism 3, the upper surface of the load-bearing beam 1 is welded with a box body 4, and the inside of the box body 4 is set There is a jacking mechanism 5, the upper surface of the jacking mechanism 5 is provided with a first support plate 6, the top of the first support plate 6 is welded with a load bearing plate 7, the upper surface of the load bearing plate 7 is provided with a sliding mechanism 8, the load beam 1 The upper surface is located on both sides of the box body 4 and is welded with N-shaped rods 9 , and the surface of the N-shaped rods 9 is rotatably connected with a rocker 10 .

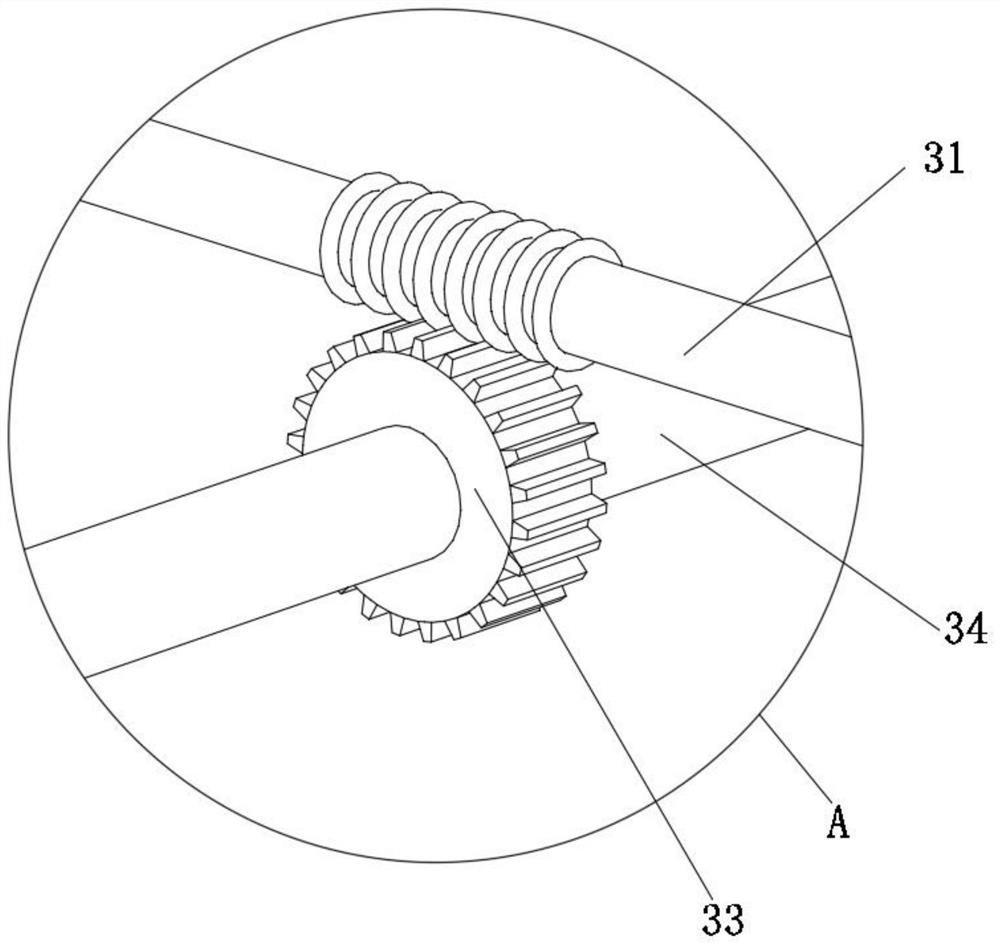

[0034]In this embodiment, the transmission mech...

Embodiment 2

[0040] Such as Figure 9-Figure 10 As shown, the jacking mechanism 5 includes a motor unit 51 and two second support plates 52, the lower surfaces of the motor unit 51 and the two second support plates 52 are fixedly connected to the bottom wall inside the box body 4, and the motor unit 51 Located between the two second support plates 52, the output end of the motor unit 51 is fixedly connected with the first meshing gear 53, the surface of the first meshing gear 53 is meshed with the second meshing gear 54, and the inside of the second meshing gear 54 is welded with Transmission rod 55, the two ends of transmission rod 55 are welded with the second transmission gear 56, the surface of the second transmission gear 56 is meshed with gear rod 57, the surface of gear rod 57 is slidingly connected with fixed pipe 58, the bottom of fixed pipe 58 It is fixedly connected with the bottom wall inside the box body 4, and the top of the gear rod 57 is welded with a push plate 59, and the...

Embodiment 3

[0045] When the portable all-round professional straightening and correction tool of this embodiment is in use, first observe whether the straightening target is in the shape of a round pipe, a square pipe, or a square. When the straightening target is in the shape of a round pipe, the round pipe can be moved from the first Pass between the fixed plate 117 and the clamping device 13, at the same time, the surface of the circular tube will also pass between the two moving plates 88, and then directly rotate the second worm 83, so that the second worm 83 will rotate the second worm 83 The turbine 84 is driven, and then the vertical rod 85 is driven by the rotation of the second turbine 84, so that the disk 87 is rotated. When the disk 87 rotates, the disk 87 on the surface will move left and right through the movable groove, so that it can be rotated according to the circular tube. After the round tube is fixed, start the power supply of the motor unit 51, so that the motor unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com