A kind of assembly tooling and assembly process of mine hollow belt roller

A technology for assembling tooling and rollers, used in metal processing, manufacturing tools, metal processing equipment, etc., can solve hidden dangers, high safety of hanging baskets and other problems, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

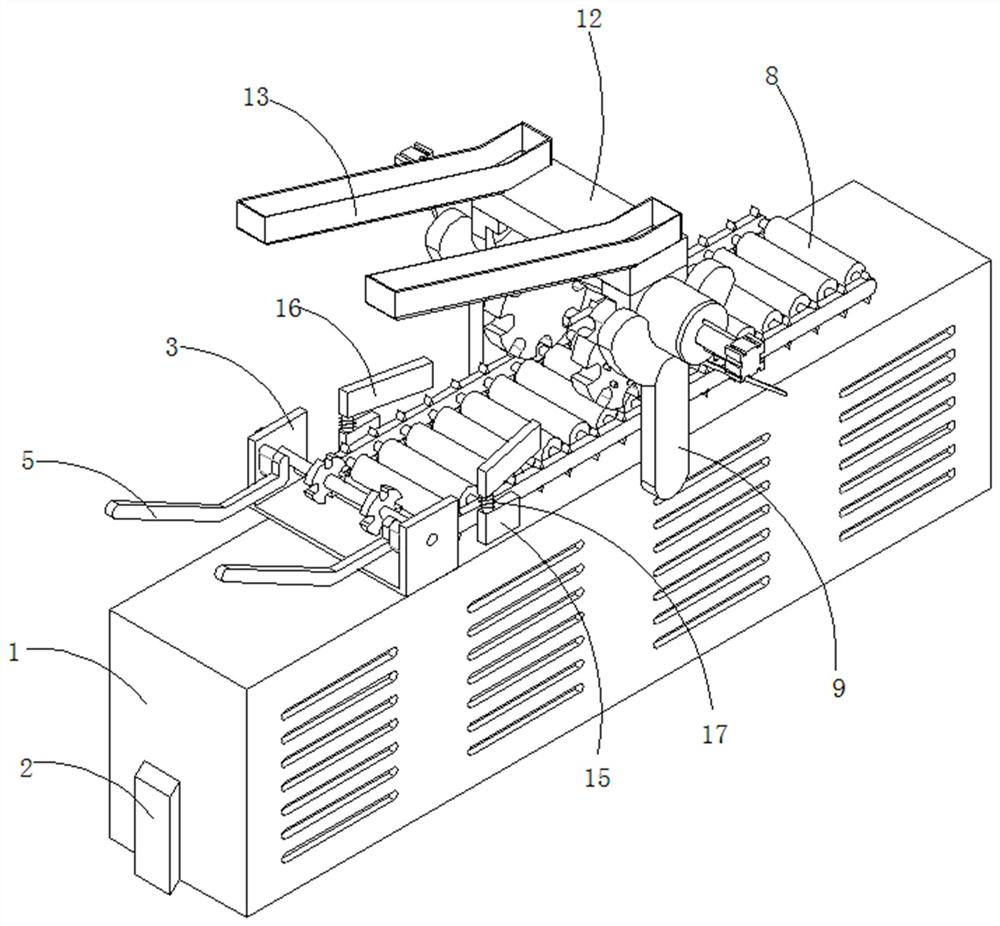

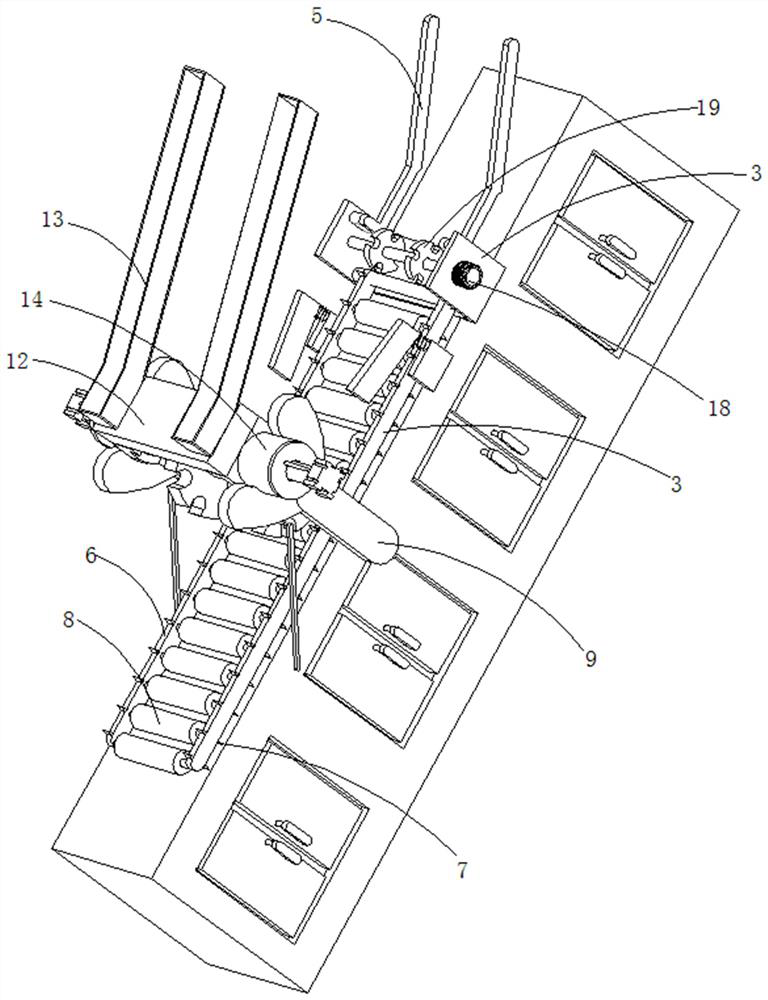

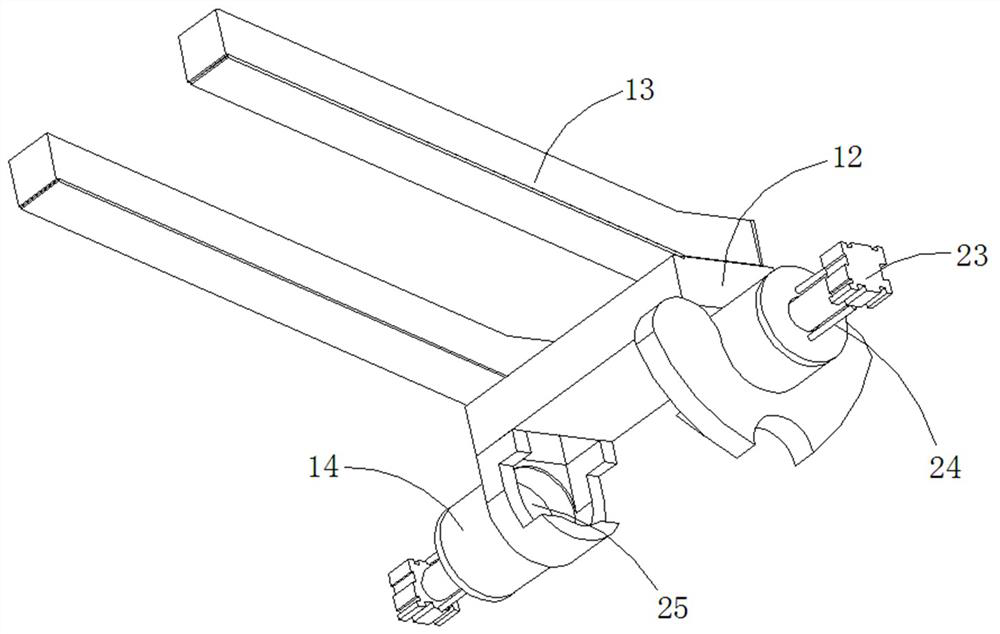

[0036] refer to Figure 1-4, a hollow belt roller assembly tool for mining, including a base 1 and an electric control box 2, the electric control box 2 is fixed on the outer side wall of the base 1, and the top of the base 1 is connected with a U-shaped mounting plate 3 in sequence along the horizontal direction And the connecting plate 4, the U-shaped mounting plate 3 is connected with a blanking frame 5 arranged obliquely, and the U-shaped mounting plate 3 is provided with a gap feeding assembly facing the blanking end of the blanking frame 5, and the connecting plate 4 is arranged symmetrically through the bracket On the top of the base 1, the outer wall of the connecting plate 4 is provided with a drive belt 6 driven by a stepping motor, and the outer wall of the driving belt 6 is fixed with evenly distributed partition plates 7, and the adjacent connecting plates 4 are rotatably connected with The roller shaft 8 and the outer wall of the base 1 are also fixedly connected...

Embodiment 2

[0045] refer to Figure 1-4 , a hollow belt roller assembly tool for mining, including a base 1 and an electric control box 2, the electric control box 2 is fixed on the outer side wall of the base 1, and the top of the base 1 is connected with a U-shaped mounting plate 3 in sequence along the horizontal direction And the connecting plate 4, the U-shaped mounting plate 3 is connected with a blanking frame 5 arranged obliquely, and the U-shaped mounting plate 3 is provided with a gap feeding assembly facing the blanking end of the blanking frame 5, and the connecting plate 4 is arranged symmetrically through the bracket On the top of the base 1, the outer wall of the connecting plate 4 is provided with a drive belt 6 driven by a stepping motor, and the outer wall of the driving belt 6 is fixed with evenly distributed partition plates 7, and the adjacent connecting plates 4 are rotatably connected with The roller shaft 8 and the outer wall of the base 1 are also fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com