Manufacturing mold for anti-peeping tempered glass film

A technology for manufacturing molds and tempered films, which is applied in the field of manufacturing molds for anti-peep tempered films, can solve the problems of taking out the finished tempered films, affecting the production efficiency of tempered films, and increasing the processing difficulty of tempered films, so as to prevent damage and be easy to manufacture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

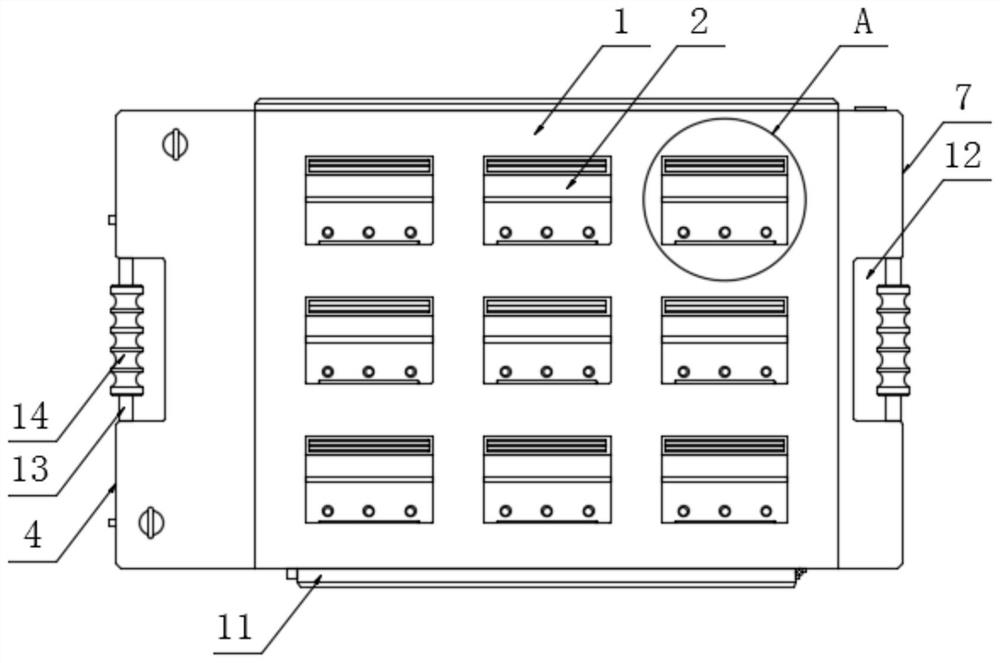

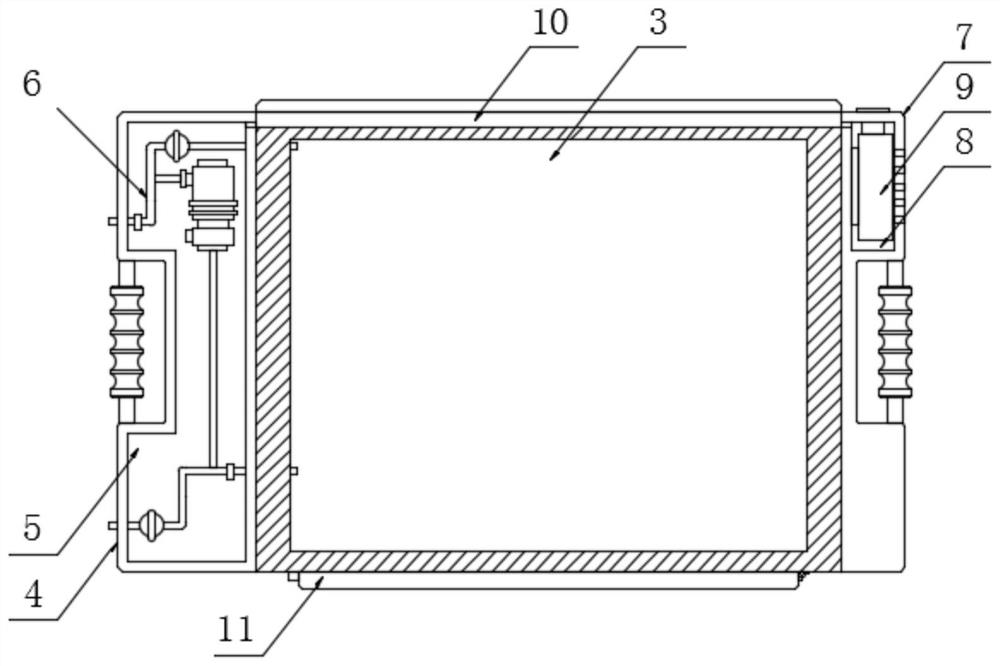

[0029] The present invention provides such Figure 1-5 A manufacturing mold for anti-peep tempered film is shown, such as figure 1 As shown, including the bottom plate 1, the top of the bottom plate 1 is provided with a plurality of tempered film bearing mechanisms 2 for placing the base material layer, and an air chamber 3 is opened inside the bottom plate 1, and the air chamber 3 is used for gas circulation. Negative pressure and positive pressure environments are formed inside the air chamber 3 .

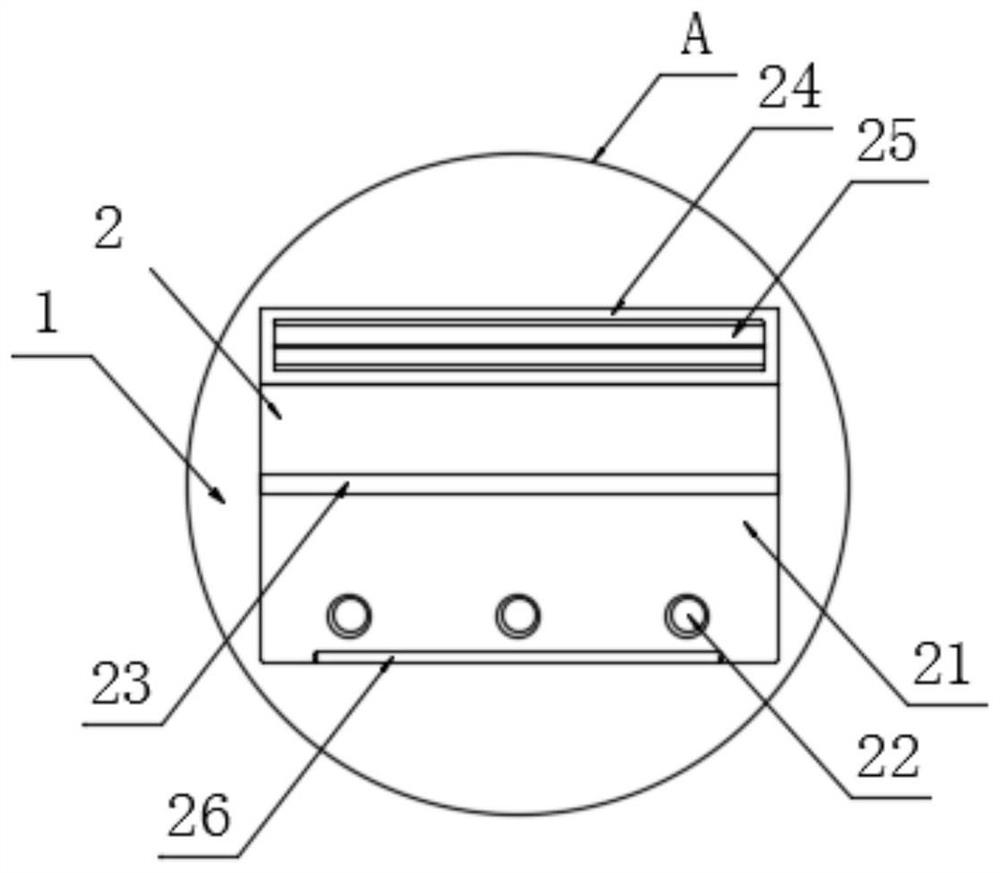

[0030] The specific setting and function of the tempered film carrying mechanism 2 will be described in detail below.

[0031] Such as image 3 and Figure 4 As shown: the tempered film carrying mechanism 2 includes a placement groove 21 where the base material layer can be placed, and a plurality of air holes 22 are opened on the bottom side of the inner cavity of the placement groove 21, and the placement groove 21 communicates with the air chamber 3 through the air holes 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com