A method for erecting main cables of a suspension bridge with tunnel-type anchorages on both sides

A technology for tunnel-type and suspension bridges, which is applied in the direction of suspension bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problems that the main cable cannot be fully covered, and achieve the effect of simple and reliable setting, convenient operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

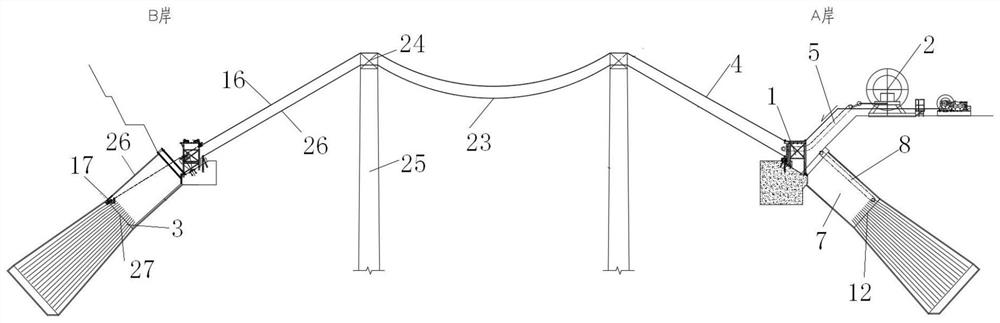

[0039] Such as Figure 1-2 , 7, shown in 10, a kind of suspension bridge main cable erection method of both sides tunnel type anchorage, comprises the following steps:

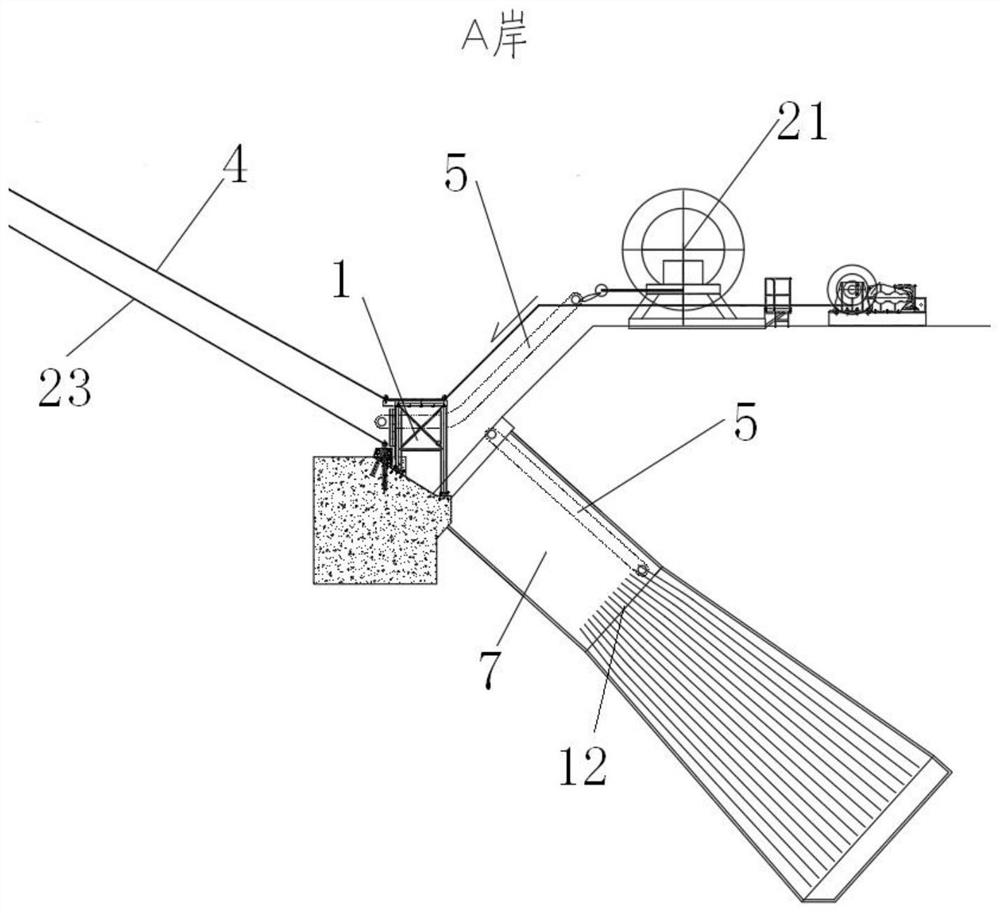

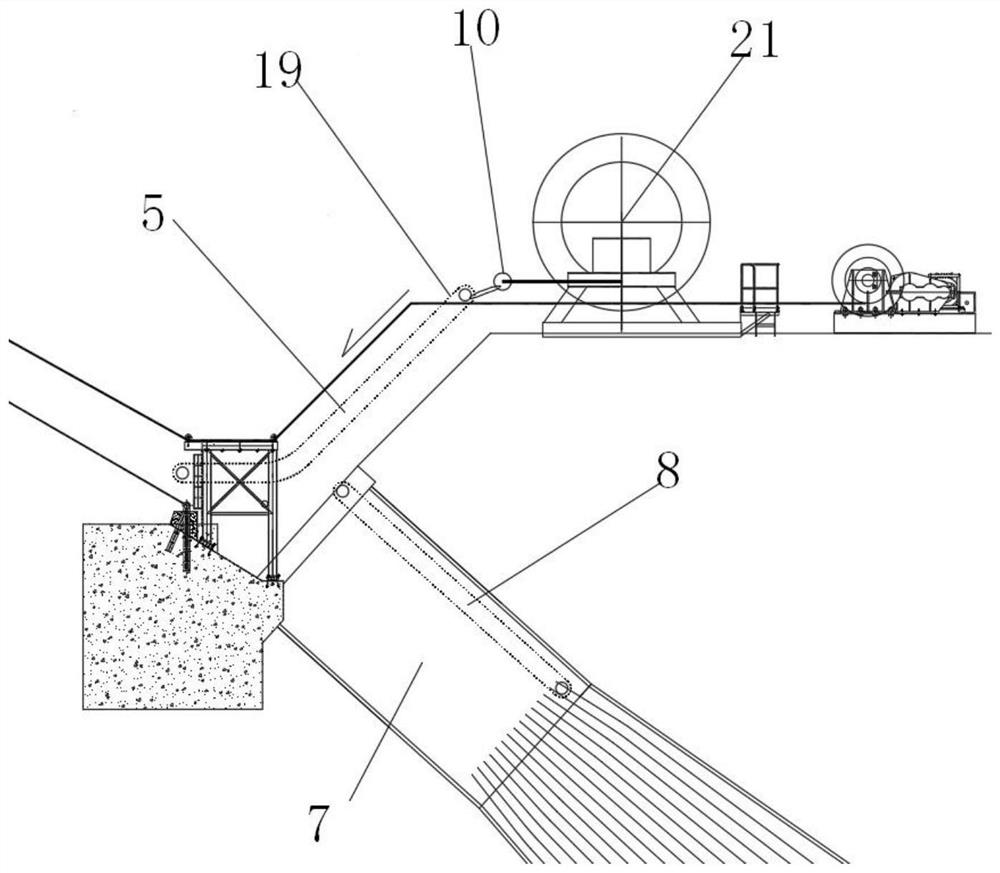

[0040] 1) Install the cable laying equipment 2 behind the anchorage gantry 1 on bank A, install the main cable traction equipment 4 between the anchorage gantry 1 on bank A and the front anchor surface 3 on bank B, install the main cable traction equipment 4 between the anchorage gantry 1 and Install traction equipment 5 and hoisting equipment 6 between the cable-laying equipment 2, install anchor chamber traction equipment 8 in the anchor room 7 in front of bank A and anchor room 26 in front of bank B, and install traction equipment 8 in the anchor room 7 in front of bank A and in front of bank B Anchor room hoisting equipment 9 is installed in the anchor room 26;

[0041] 2) The anchor head 10 of the main cable is connected to the traction device 5, and the anchor head 10 of the main cable is pulled to the ...

Embodiment 2

[0048] On the basis of Example 1, such as Figure 5-6 As shown, further, the main cable pulling device 4 adopts a circular pulling device, and the working range of the main cable pulling device 4 is that the anchorage gantry 1 on bank A is pulled to the front anchor surface 3 on bank B.

[0049] Such as Figure 3-4 As shown, further, the traction device 5 adopts a circular traction device, and the working range of the traction device 5 is from the cable-laying device 2 to the anchorage gantry 1 on the bank A.

[0050] Such as Figure 8-9 As shown, further, the traction equipment 8 in the anchor chamber adopts circular traction equipment, and the working range of the traction equipment 8 in the anchor chamber is from the anchorage gantry 1 on bank A to the anchor surface 12 in front of bank A.

[0051] Main cable traction equipment 4, traction equipment 5 and anchor chamber traction equipment 8 all adopt circular traction equipment, which has less traction equipment, saves ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com