Indoor large-scale comprehensive simulation drilling test platform and method for engineering geological parameter prediction

A technology of engineering geology and test platform, applied in measurement, teaching model, earthwork drilling, etc., can solve the problem of difficulty in carrying out on-site tests at tunnel construction sites, and achieve the effect of reducing the number of experiments, improving the efficiency of experiments, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

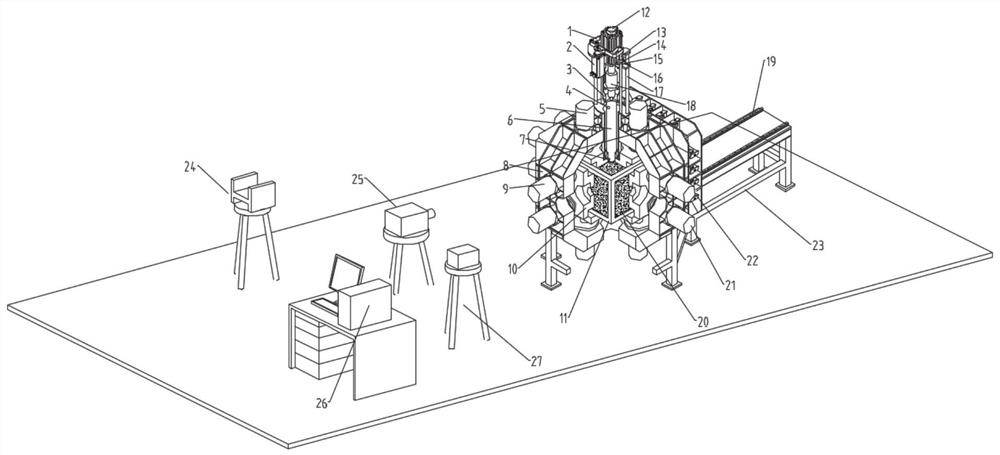

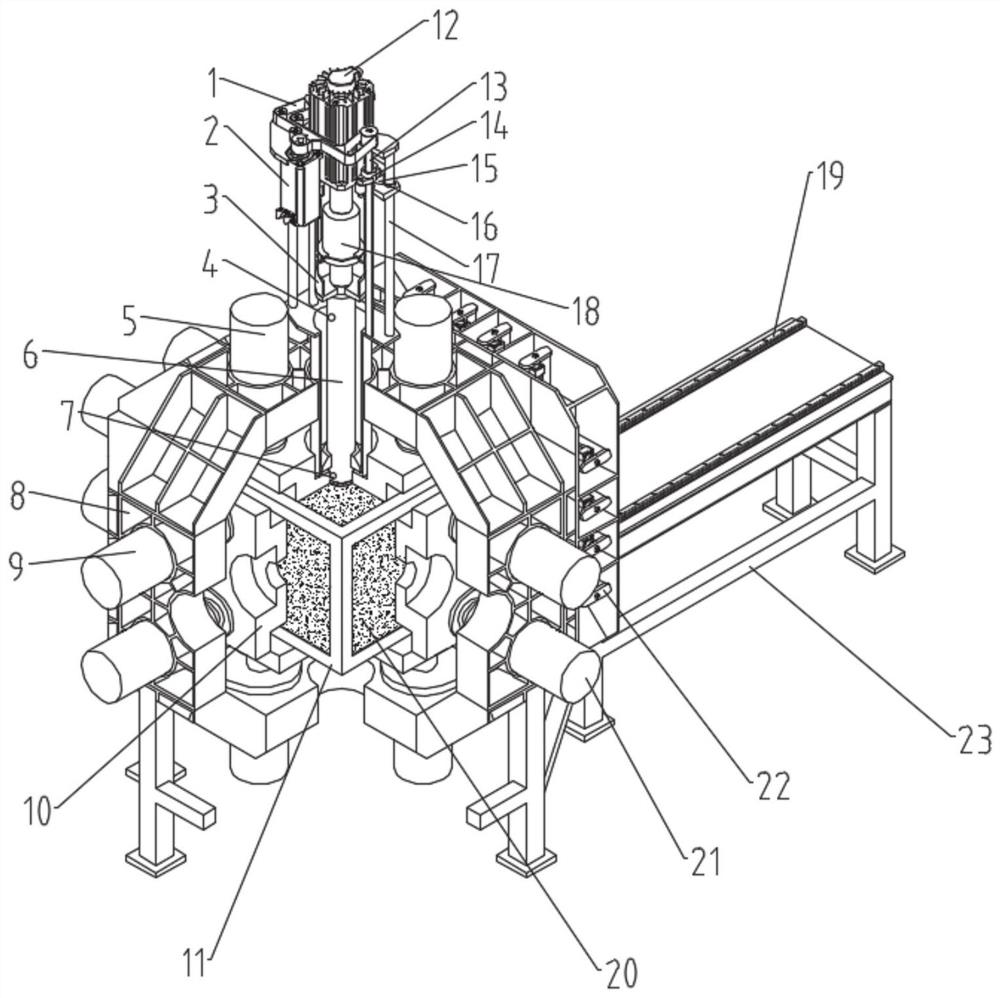

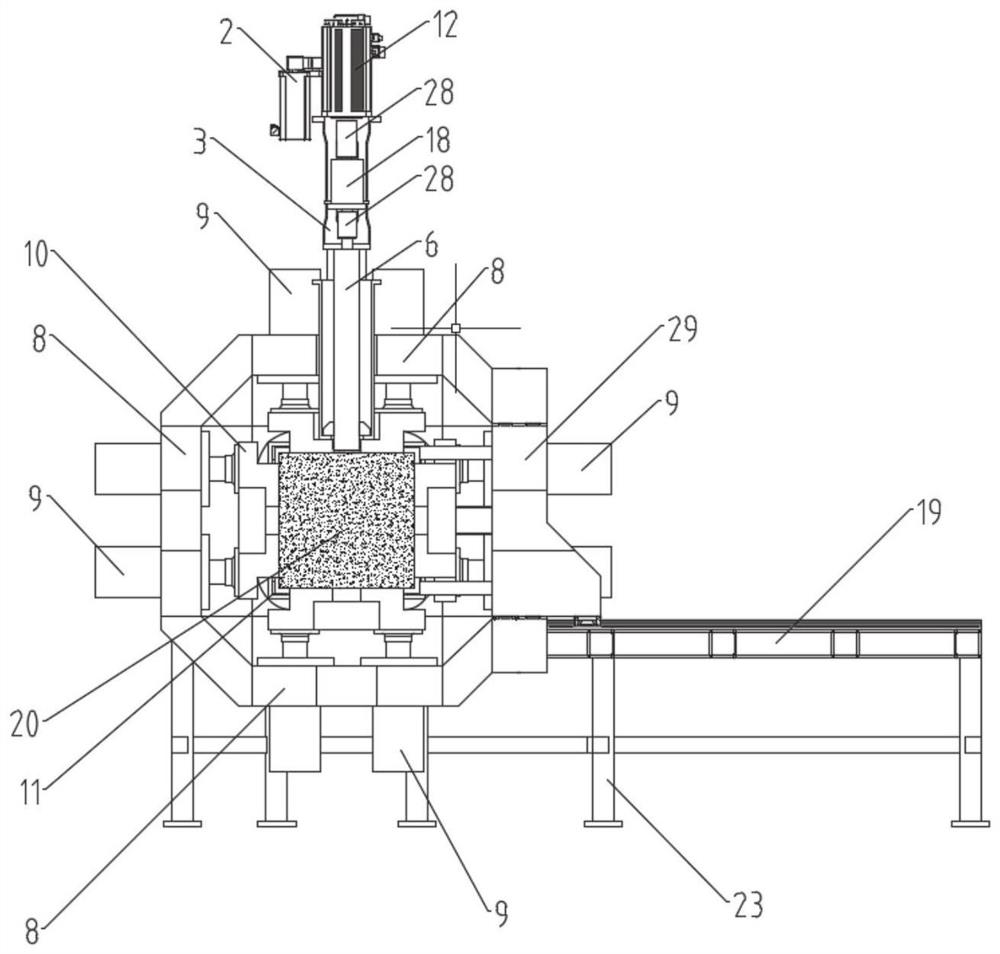

[0032] In a typical embodiment of the present invention, such as figure 1 As shown, Embodiment 1 discloses a large-scale comprehensive simulation drilling test platform for engineering geological parameter prediction, including a casing, a rock sample transmission and unloading system, a multi-directional drilling system, a complex geological environment quantitative simulation system, and a data acquisition and processing system. The platform is made of rock blocks in inclined strata, and the specific connection relationship is that a multi-directional drilling system is installed at the end of the rock sample transmission and unloading system, and a complex geological environment quantitative simulation system is installed around the multi-directional drilling system. The quantitative simulation system can cooperate with the multi-directional drilling system to drill the rock sample 20 at the same time, the data acquisition and processing system collects the information of th...

Embodiment 2

[0051] In a typical implementation of the present invention, a large-scale comprehensive simulated drilling test method in the engineering geological parameter prediction room is disclosed, using the large-scale comprehensive simulated drilling test platform in the engineering geological parameter prediction room as claimed in claim 1, the rock The simulation and monitoring of body drilling process includes the following steps:

[0052] 1) Cut and polish the original rock to a suitable size or prefabricate it with similar materials;

[0053] 2) Place the cut and polished raw rock or prefabricated similar rock blocks on the belt conveyor, and open the movable reaction wall 298 .

[0054] 3) The rock sample 20 is transported and installed on the holder 11 of the rock sample 20, and fixed and installed by the locking pin 22. Adjust the hydraulic control system, control the hydraulic push plate 10, load the prefabricated original rock or similar rock blocks on six sides, and simu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com