External connection structure of shock absorber

A technology of external connection and shock absorber, which is applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve problems affecting four-wheel alignment, uneven alignment, torque loosening and retreat, etc., and achieve four-wheel Stable parameters such as positioning, eradicate frictional noise, and avoid the effects of torque loosening and retreating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

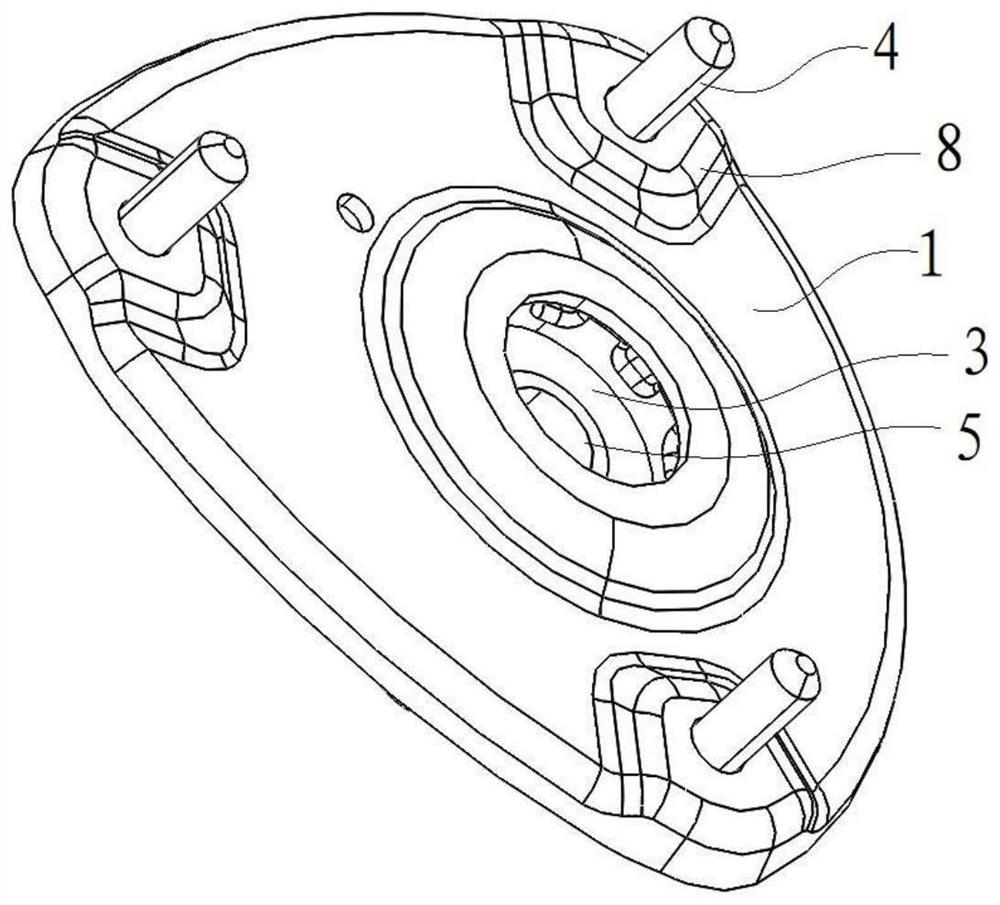

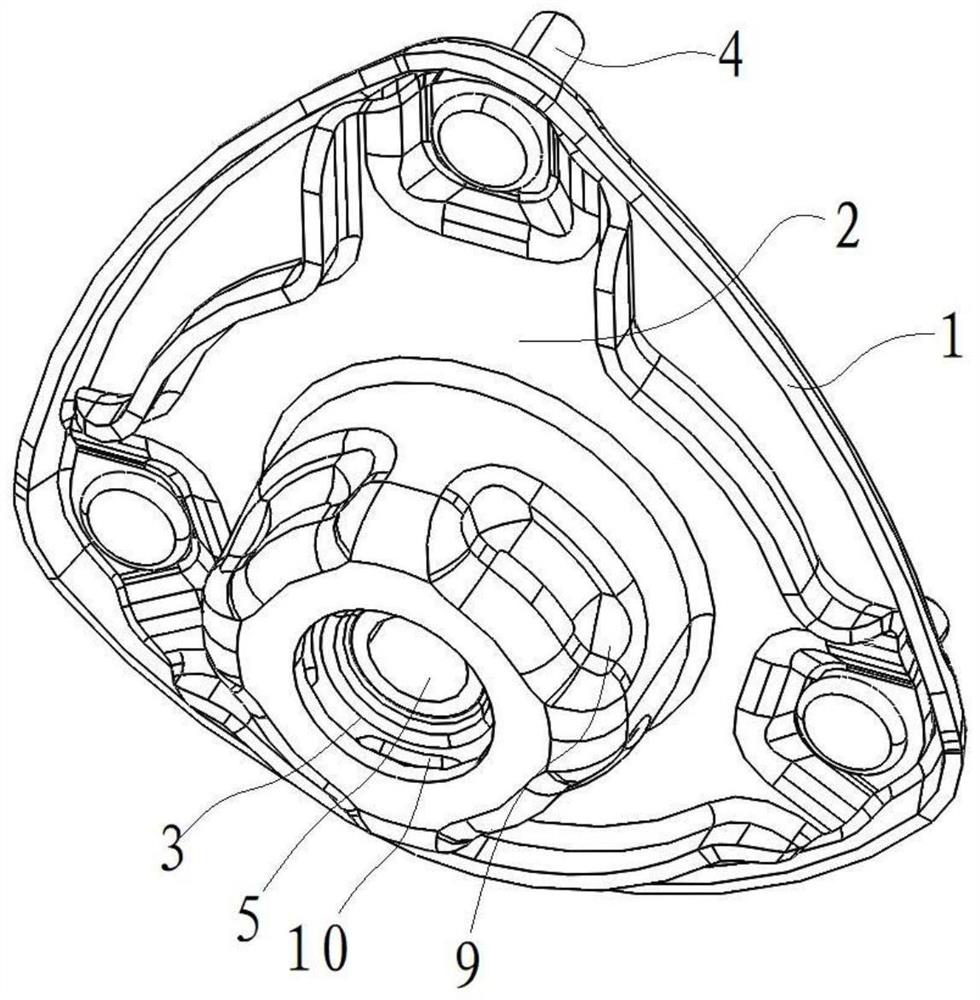

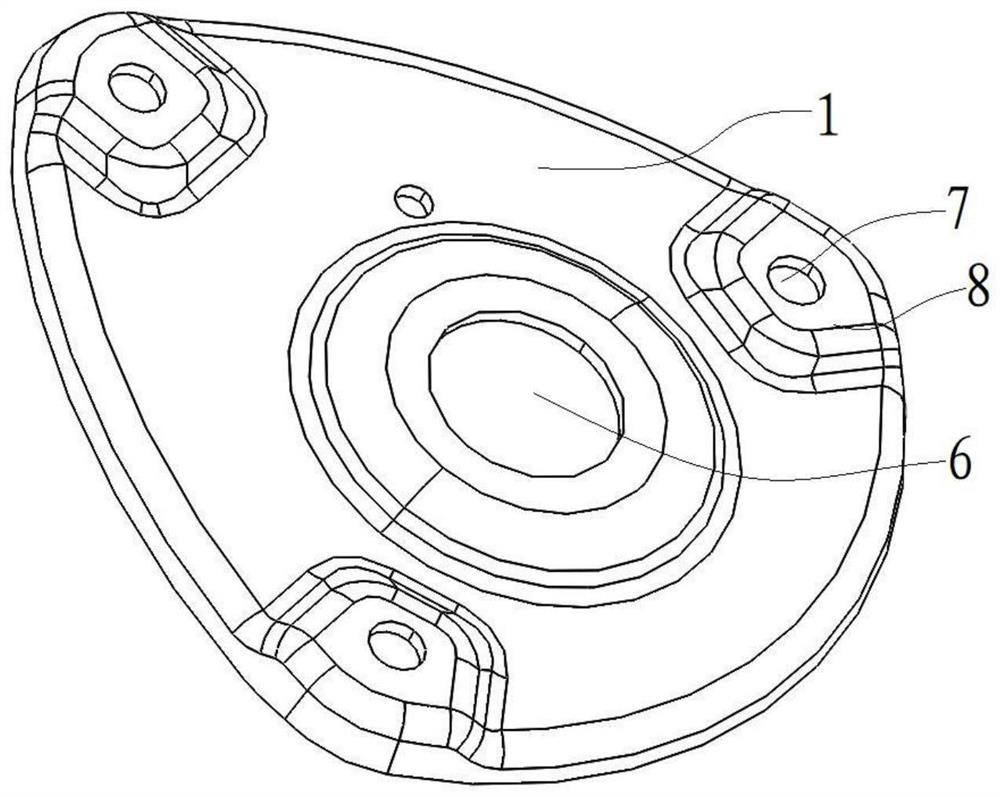

[0039] Such as Figure 1 to Figure 5 As shown, the embodiment of the present invention provides an external connection structure of a shock absorber, including an upper plate 1, a lower plate 2, a vibration isolation rubber 3, a stud 4 and an inner casing 5, wherein:

[0040] The upper plate 1 is provided with a first through hole 6 and a second through hole 7. The first through hole 6 is a circular hole, and may also be in other shapes, such as a waist-shaped hole. Assembled with the piston rod of the device, a plurality of second through holes 7 are provided, and the plurality of second through holes 7 are annularly spaced in the circumferential direction of the first through hole 6 . In this embodiment, the cross-section of the upper plate 1 is an equilateral triangle structure, which enh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com