Anti-leakage structure of vacuum blow-down valve

A vacuum blowdown and anti-leakage technology, applied to the valve shell structure, valve details, valve device, etc., can solve the problems of unreasonable connection mode, large use limitation and poor sealing performance of the vacuum blowdown valve, so as to reduce the failure of use rate, reduce failure rate, good effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

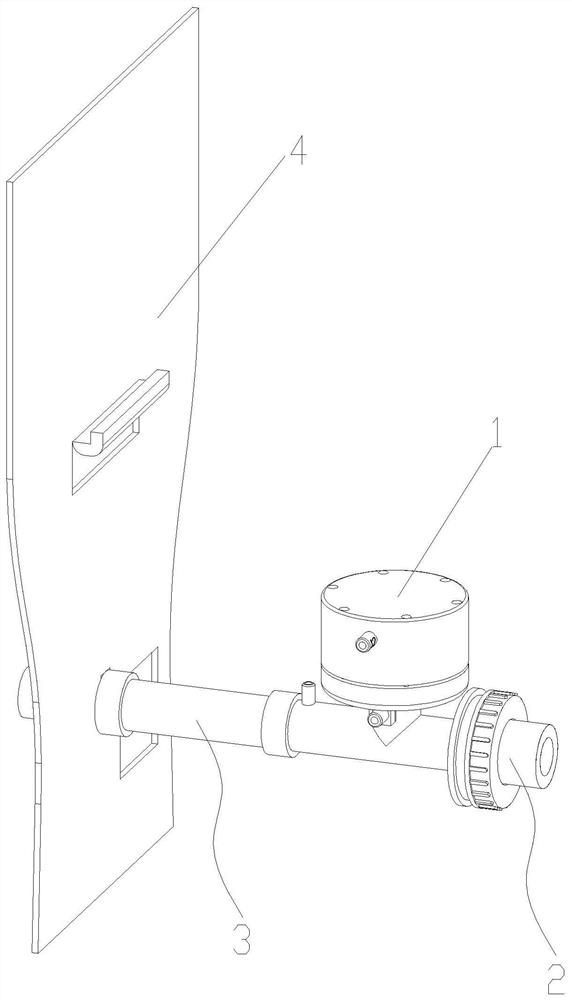

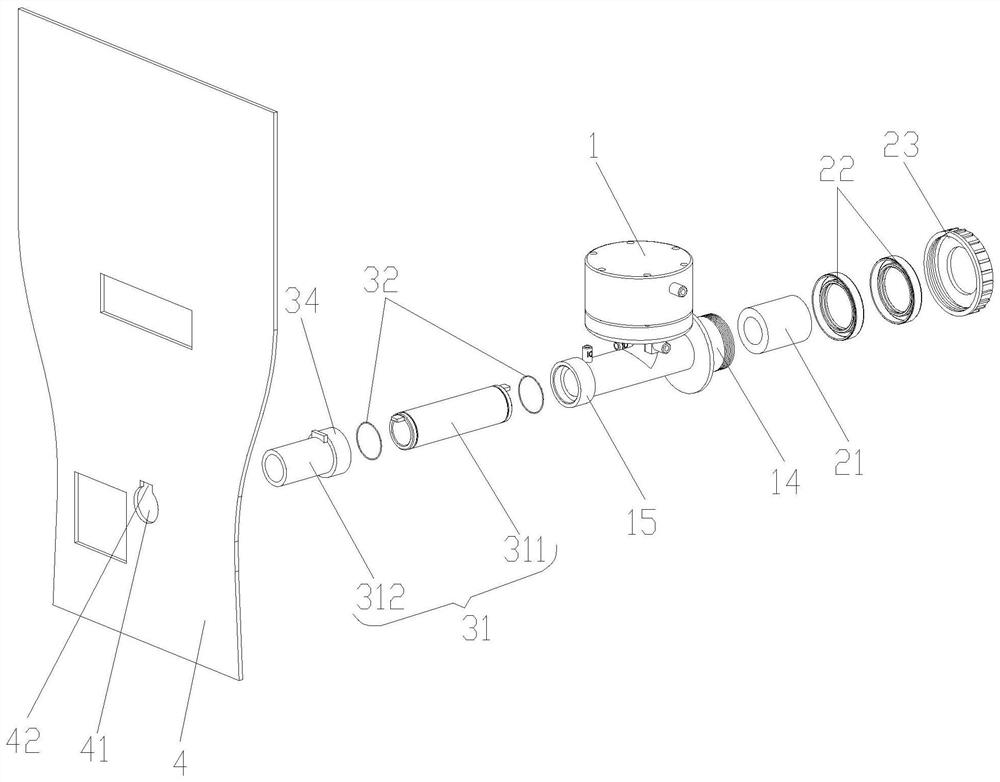

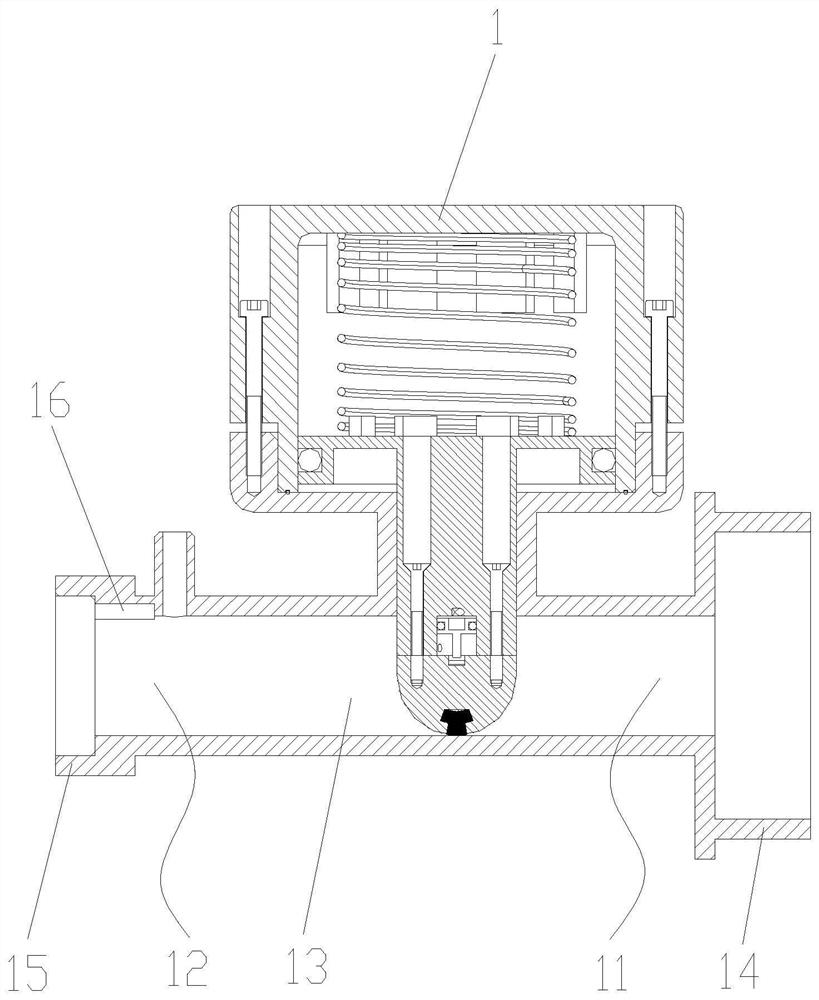

[0041] Such as figure 1 , figure 2 As shown, an anti-leakage structure of a vacuum blowdown valve includes a vacuum blowdown valve 1 capable of on-off sewage flow, an upstream connection component 2 and a downstream connection component 3 respectively arranged on both sides of the vacuum blowdown valve 1; simply, the vacuum blowdown The valve 1 is provided with a sewage flow end 11 and a negative pressure flow end 12 along the sewage flow direction; the upstream connection component 2 is sealed and connected with the sewage flow end 11, and is used to realize the flow of sewage into the vacuum sewage valve 1; the downstream connection component 3 is connected to the negative pressure flow end 12 is sealed and connected, and is used to realize the discharge of sewage through the opened vacuum drain valve 1. The side of the downstream connection assembly 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com