Kitchen air conditioning system

An air-conditioning system and air-conditioning technology, applied in air-conditioning systems, ventilation systems, shielding with air flow, etc., can solve the problems of energy waste, heat removal, heat waste, etc., and achieve the effect of a compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

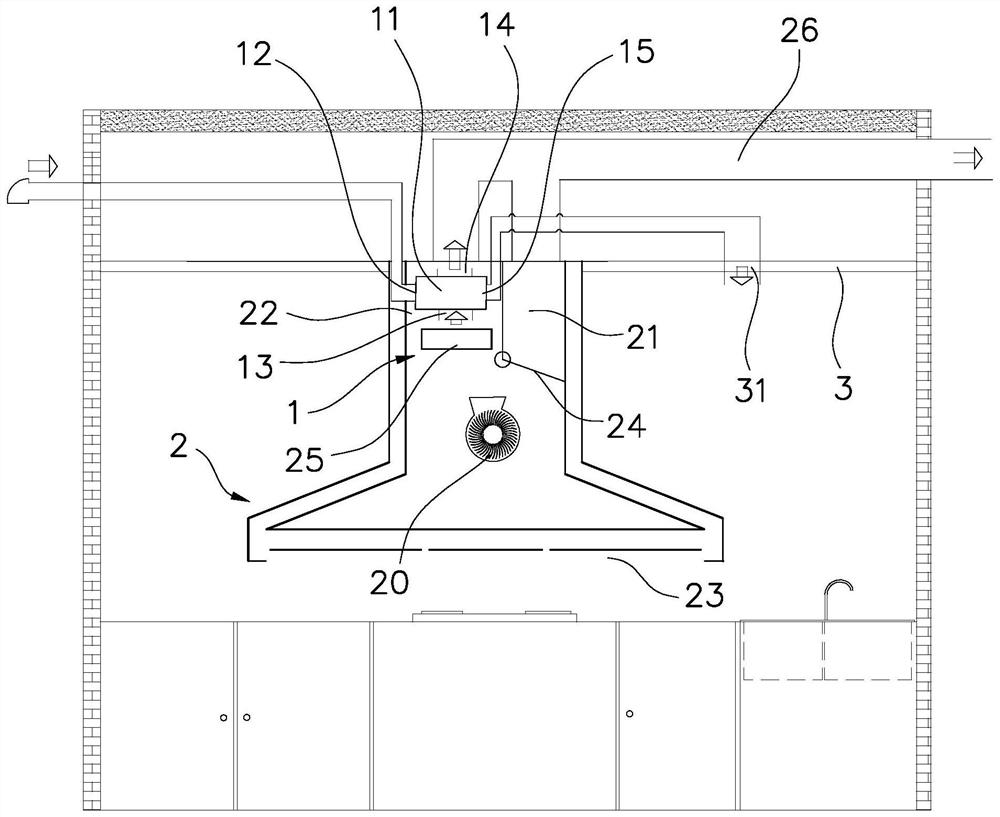

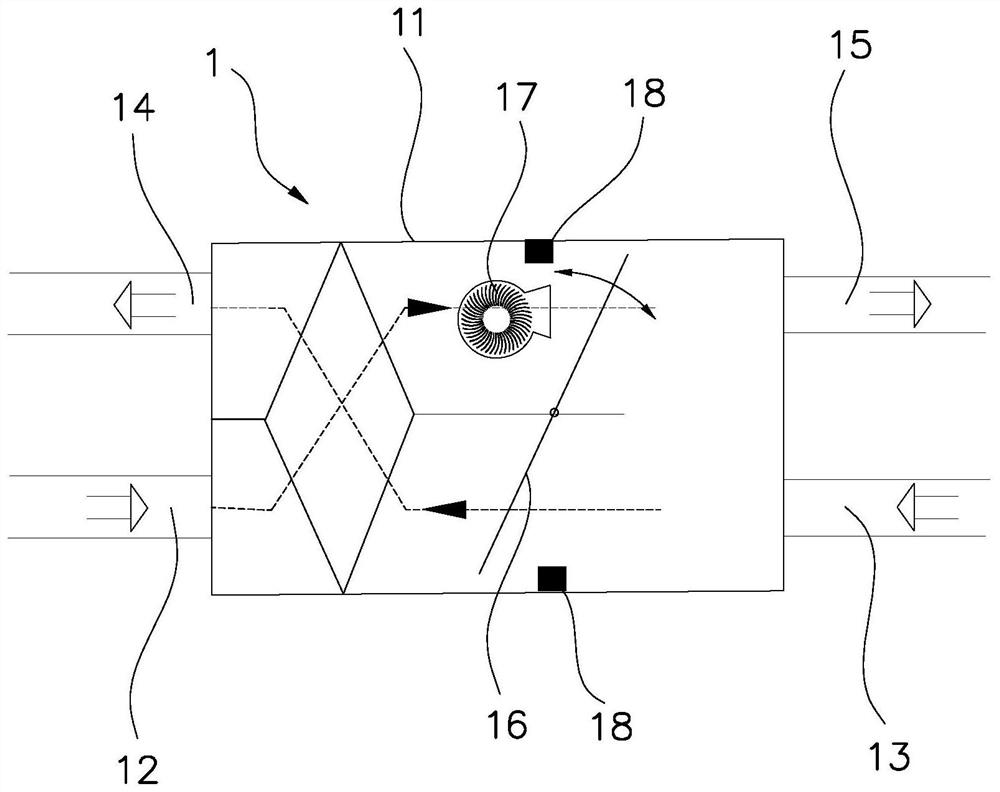

[0017]Such asfigure 1 withfigure 2As shown, the kitchen air conditioning system in this embodiment includes a total heat exchanger 1 and an oil fume suction assembly 2. Among them, the total heat exchanger 1 is integrally integrated on the oil fume suction assembly 2 as an air conditioning assembly. The shell 11 of the total heat exchanger 1 has a first air inlet 12, a second air inlet 13, a first air outlet 14 and a second air outlet 15. The first air inlet 12 communicates with the outdoors, the first air outlet 14 communicates with the outdoors or a public flue, and the second air outlet 15 communicates with the kitchen room through the air supply opening 31 on the kitchen ceiling 3.

[0018]A first air valve 16 for switching wind direction and a fan 17 for providing wind power are installed inside the housing 11, and a block 18 for matching with the first air val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com