Backheating type sodium rhodanate-ammonia absorption heat pump system

A sodium thiocyanate and ammonia absorption technology, applied in the field of air conditioning, can solve problems such as difficult to use, small cooling capacity, and difficult adjustment of cooling capacity, and achieve high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

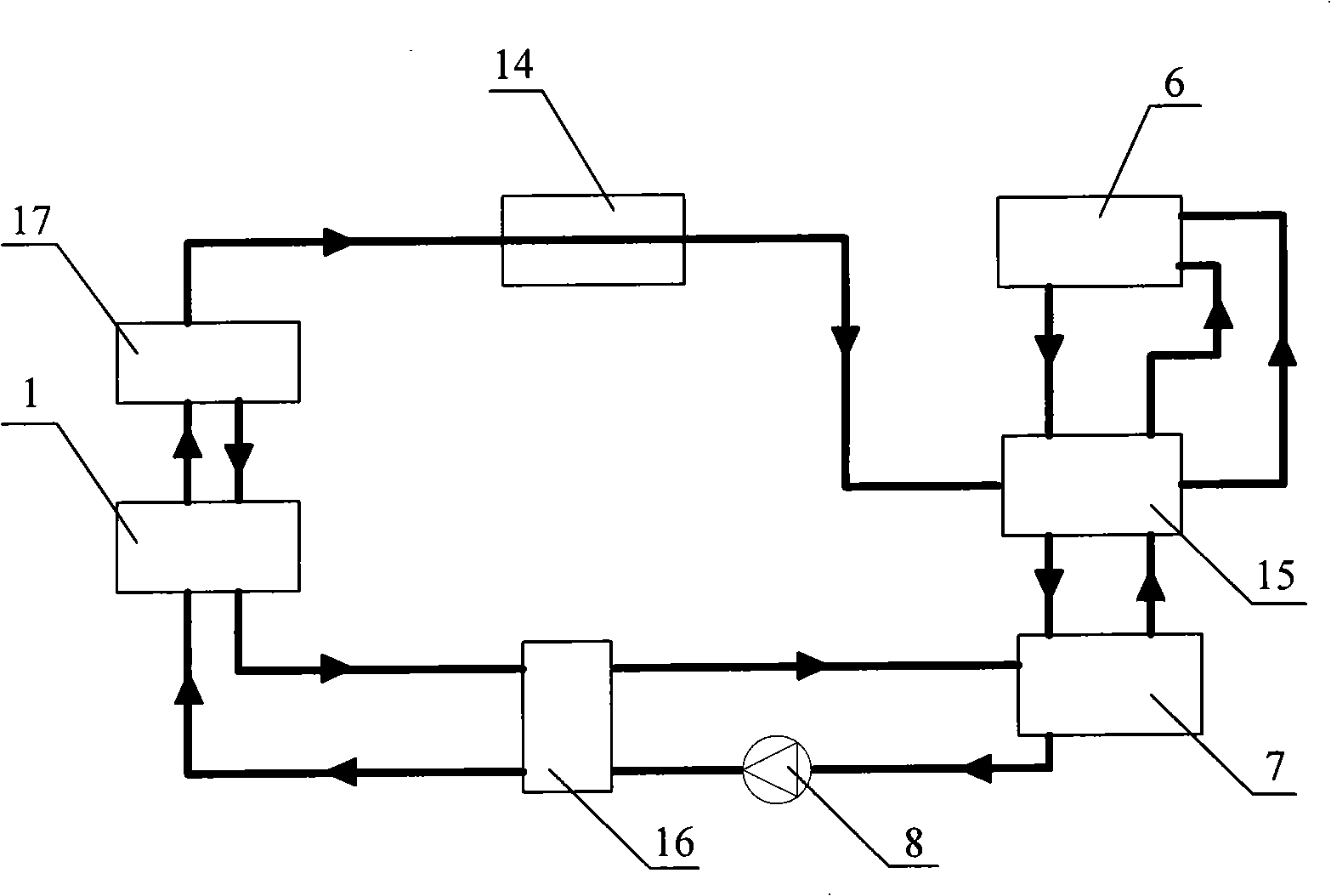

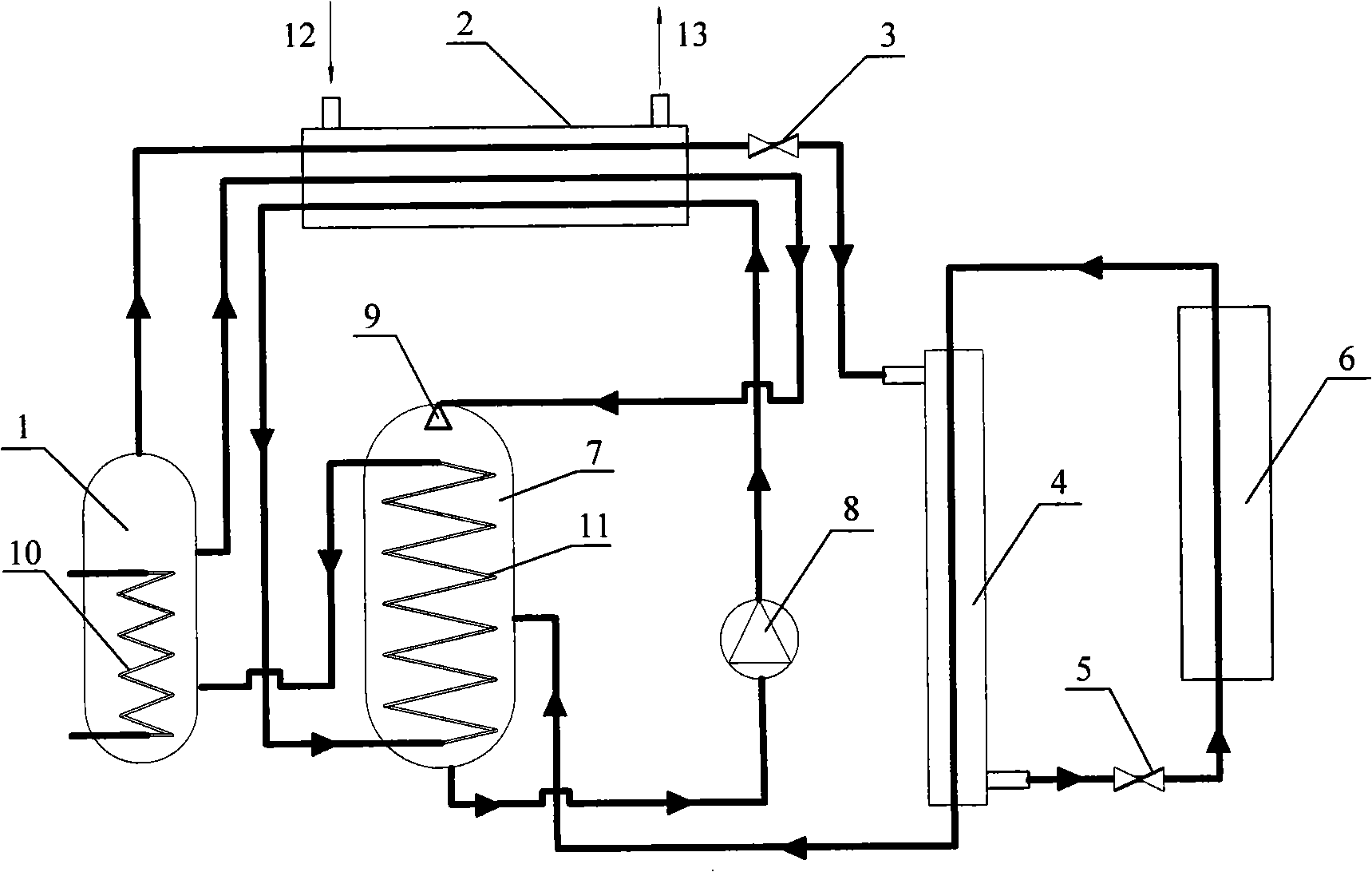

[0014] Attached below figure 2 The present invention is described further:

[0015] The system includes a generator 1 , an evaporator 6 , an absorber 7 , a solution pump 8 , a multi-inner tube-in-pipe heat exchanger 2 and a single inner tube in-pipe heat exchanger 4 . The outer tubes of the multi-inner tube-in-tube heat exchanger 2 are respectively connected to the circulating water inlet 12 and the circulating water outlet 13, and one end of the three inner tubes is respectively connected to the ammonia steam outlet of the generator 1, the dilute sodium thiocyanate-ammonia solution outlet and the absorber The inlet of the heat exchange coil 11 inside 7 is connected, and the other ends of the corresponding three inner pipes are respectively connected to the primary throttle valve 3, the nozzle 9 in the absorber 7, and the concentrated sulfur at the bottom of the absorber 7 through the solution pump 8. The sodium cyanate-ammonia solution outlet is connected. One end of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com