A food refrigeration system

A technology of food refrigeration and cold storage, which is applied in the direction of refrigerators, refrigerators, coolers, etc., which can solve the problems of food deterioration, food supplementary air conditioning, etc., and achieve the effect of avoiding temperature rise and ensuring the effect of refrigeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

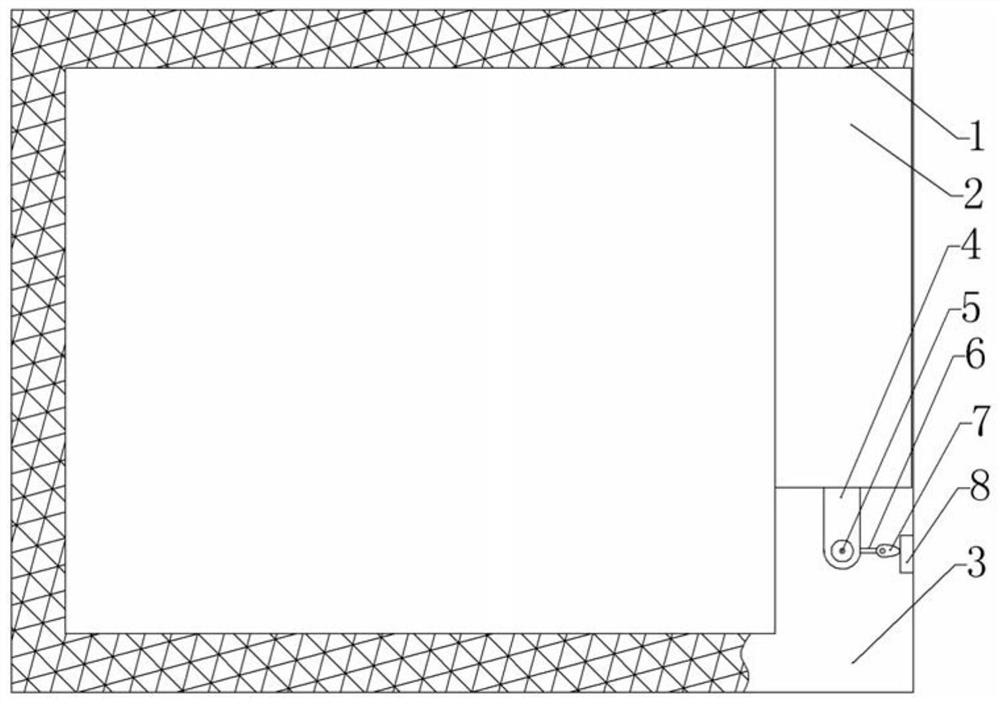

[0034] Such as figure 1 As shown, a food refrigeration system includes a cold storage, and the inner wall of the cold storage is provided with several figure 2 The cooling pipe shown in the cooling pipe is connected with a refrigerator (not shown in the figure), and the refrigerator adopts a compression refrigerator in the prior art, and the refrigerator is installed outside the cold storage. There is an annular cooling tank 3 on the floor of the cold storage. A liquid storage tank 2 is installed in the cooling tank 3. The liquid storage tank 2 is connected between the cooling pipe and the refrigerator. The liquid storage tank 2 is connected with a liquid outlet pipe 4 for feeding the cooling tank. Coolant is discharged in 3, a pressure valve (not shown) is installed on the liquid outlet pipe 4, a support net 1 is mounted on the top of the cooling tank 3, and the support net 1 is connected horizontally with the ground of the cold storage.

[0035] In the cold storage, a powe...

Embodiment 2

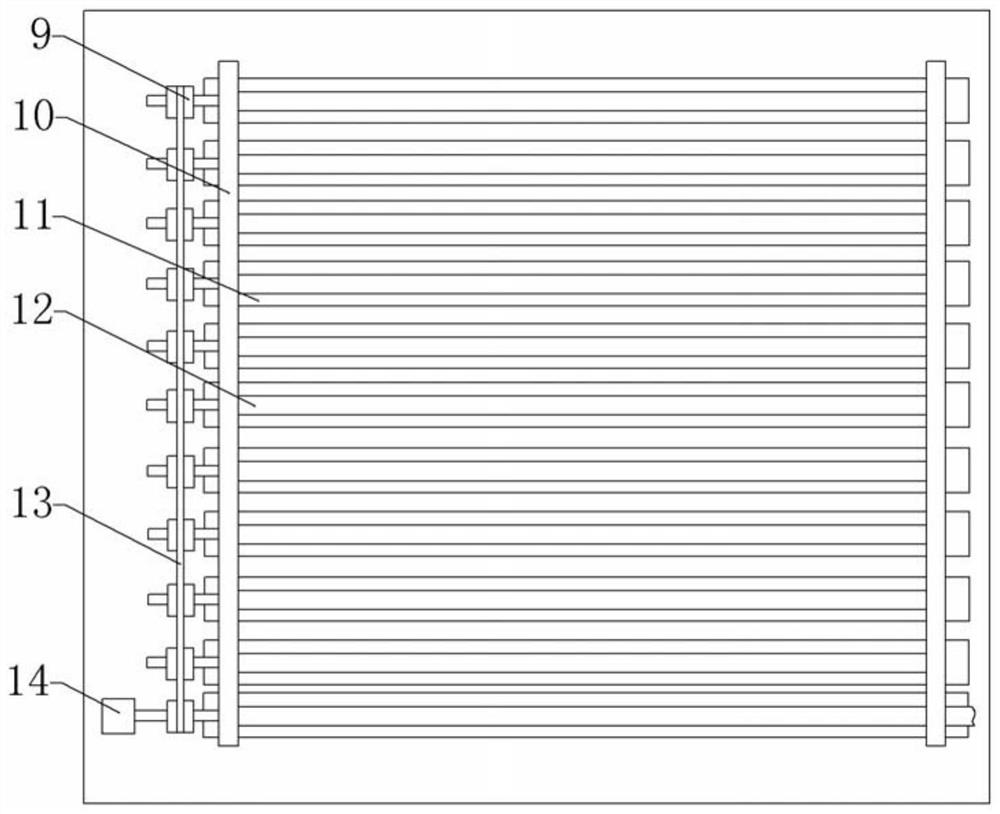

[0043] Such as figure 2 with 3 As shown, the cooling pipe is located above the cooling tank 3, and the cooling tank 3 is connected with a sewage pipe (not shown in the figure), which extends to the outside of the cold storage, and a valve is installed on the sewage pipe. The cooling pipes include several horizontal pipes 12 and vertical pipes 10, and on each side inner wall of the cold storage, several horizontal pipes 12 and two vertical pipes 10 are fixed by bolts (only one inner wall of the cold storage is shown in the figure), two The vertical pipes 10 communicate with the two ends of all the horizontal pipes 12 respectively, and all the horizontal pipes 12 are rotatably connected to the vertical pipes 10 (thread connection may be adopted) and communicated.

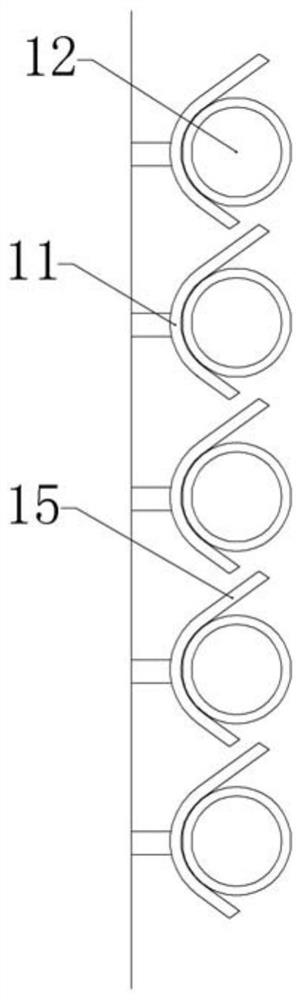

[0044] A derusting mechanism for derusting the horizontal tube 12 is installed in the cold storage. The derusting mechanism includes a grinding plate 11 fixed on the inner wall of the cold storage by bolts. The grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com