Fatigue design method for test-oriented helicopter rotor metal part

A helicopter rotor and design method technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as test cost and development cycle waste, failure mode life asynchrony, and acceleration difference, and avoid premature failure. , The effect of saving development cycle and test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

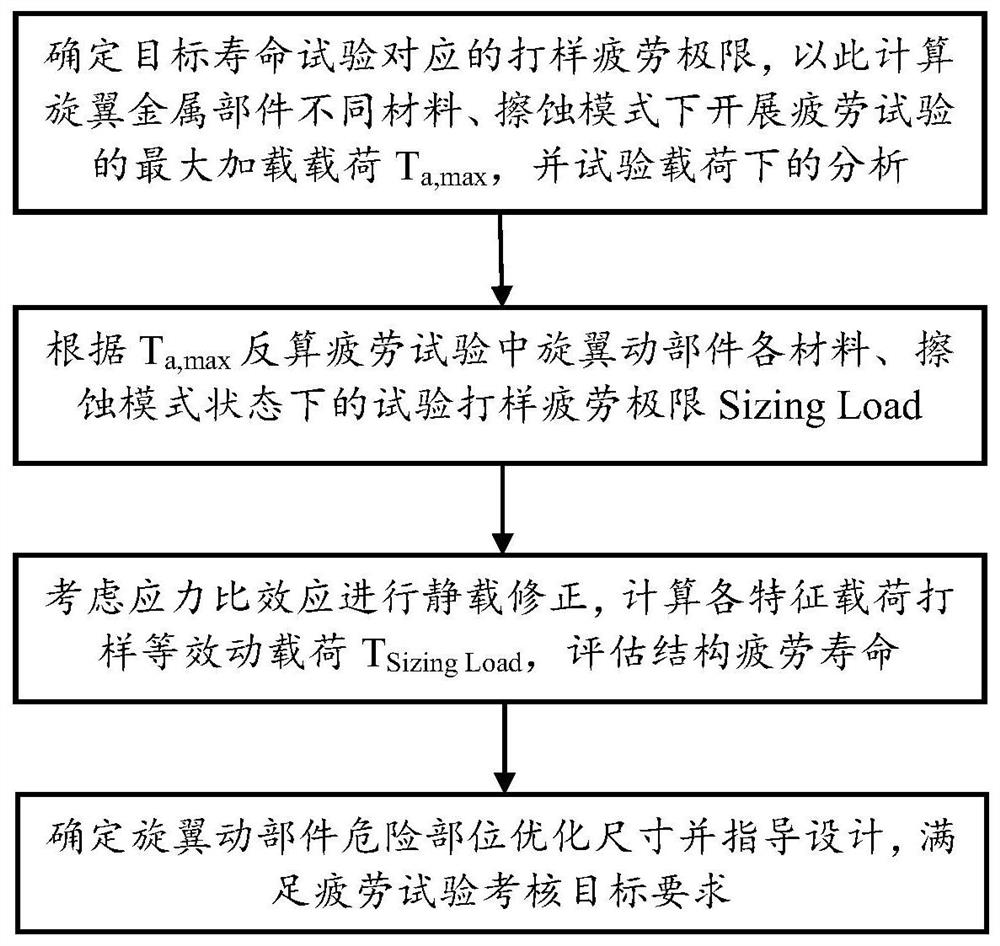

[0034] see figure 1 , the present invention proposes a kind of test-oriented helicopter rotor metal parts fatigue design method, realizes metal parts fatigue life evaluation and structural design, and this method comprises the following steps:

[0035] Step 1, fatigue test load analysis under different metal parts materials and erosion states

[0036] Based on the cumulative damage theory, the fatigue performance characterization model of helicopter rotor components is established:

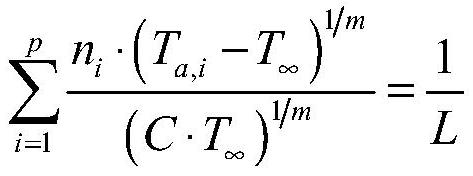

[0037]

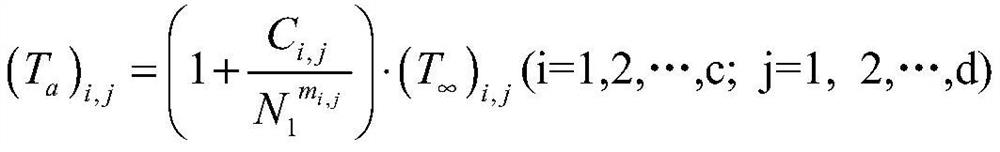

[0038] In the formula, C and m are the slope and intercept parameters of the metal fatigue curve, which are determined according to the test data; T a,i (i=1,2,...,p) is a set of dynamic loads of the characteristic load T in each flight state; n i (i=1,2,...,p) is the frequency of each flight state per hour; L is the high-cycle fatigue life of the helicopter structure; T ∞ is the high cycle fatigue limit of the characteristic load T corresponding to the life L. Equation (1) establi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com