Processing device

A technology for processing devices and holding surfaces, which is applied in the direction of static electricity, electrical components, and electrical solid devices, and can solve problems such as device quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

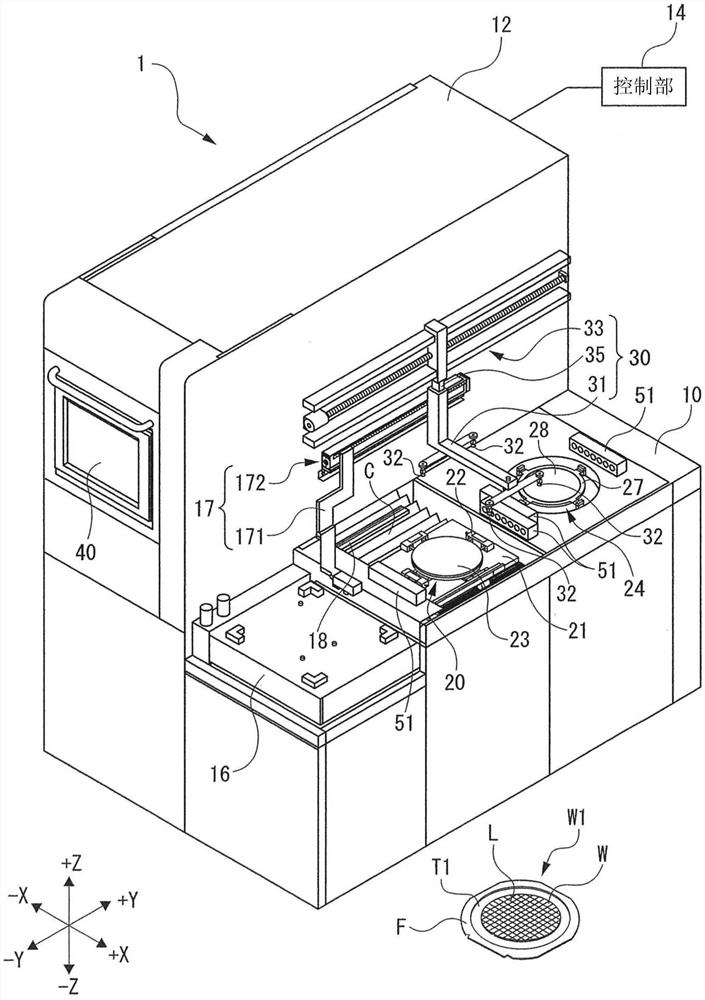

[0027] Such as figure 1 As shown, the cutting device 1 of this embodiment is an example of a processing device, and performs cutting processing on a wafer W as a workpiece.

[0028] The wafer W has a substantially circular shape, and grid-like planned dividing lines L are formed on the front surface. Various devices (not shown) are formed in each region divided by the planned division line L. As shown in FIG.

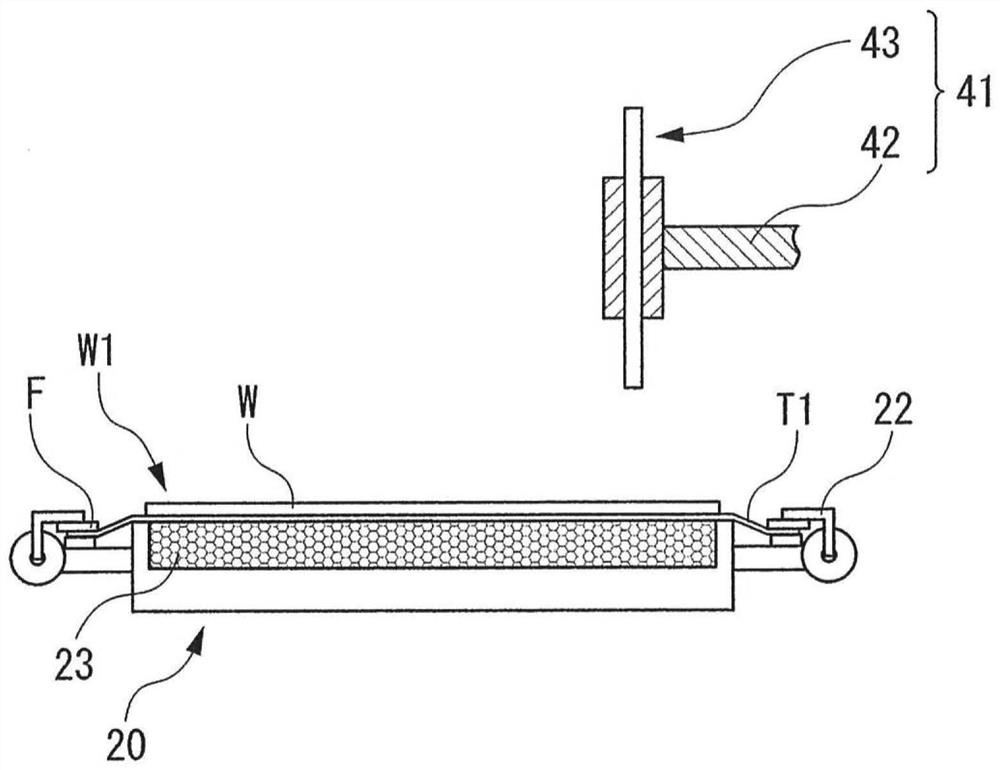

[0029] A dicing tape T1 is attached to the back surface of the wafer W. The ring frame F is attached to the outer periphery of the dicing tape T1. That is, the workpiece group W1 is formed by affixing and integrating the dicing tape T1 on the ring frame F and the wafer W disposed at the opening of the ring frame F.

[0030] In this manner, the wafer W is processed by the cutting device 1 in a state supported by the workpiece group W1 of the ring frame F via the dicing tape T1 . Furthermore, the workpiece group W1 is accommodated in a cassette not shown and carried i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com