Motors and electronic equipment with motors

A motor and stator technology, applied in the field of motors and electronic equipment with motors, can solve the problems of reducing production manpower and cost, insufficient iron core flatness, multiple workmanship, etc., to reduce production manpower and cost, reduce bearing failure and damage, The effect of improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

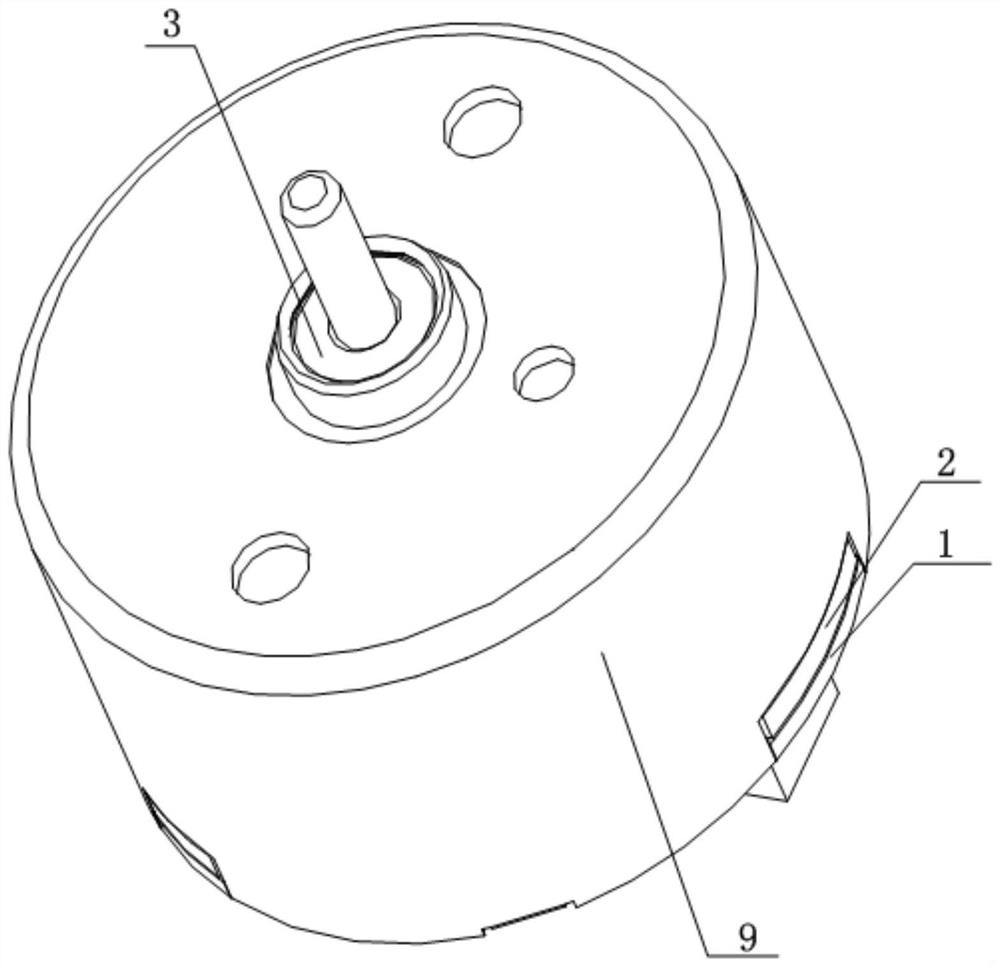

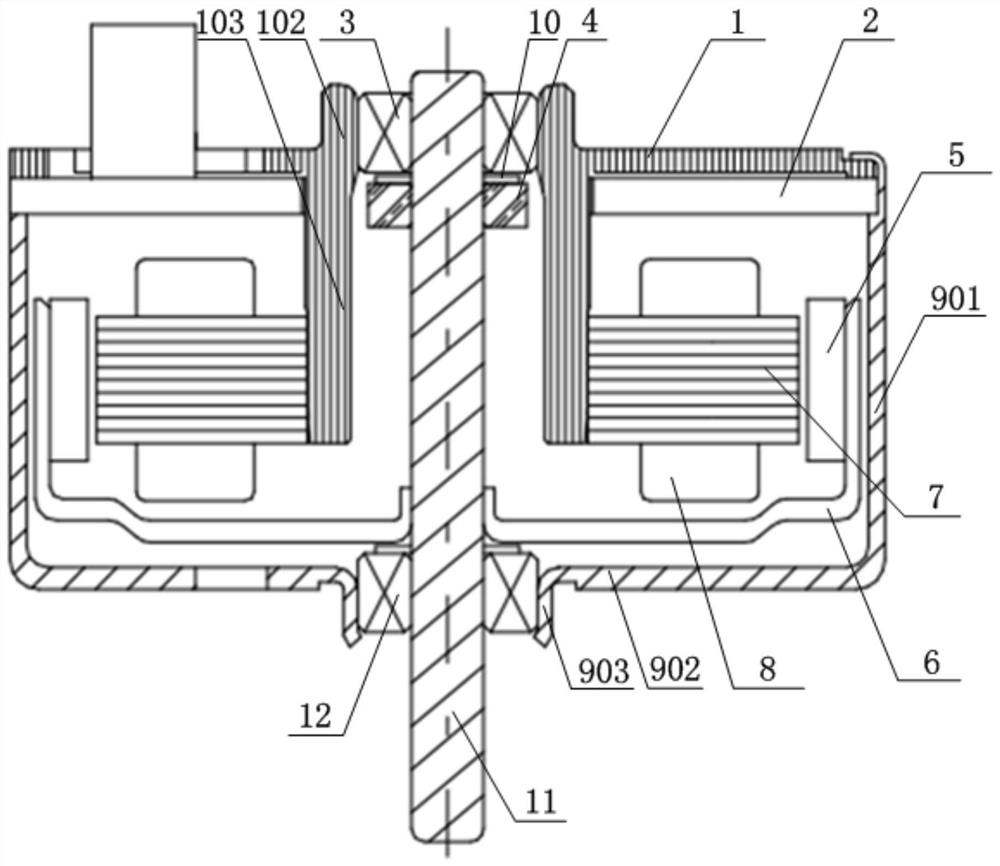

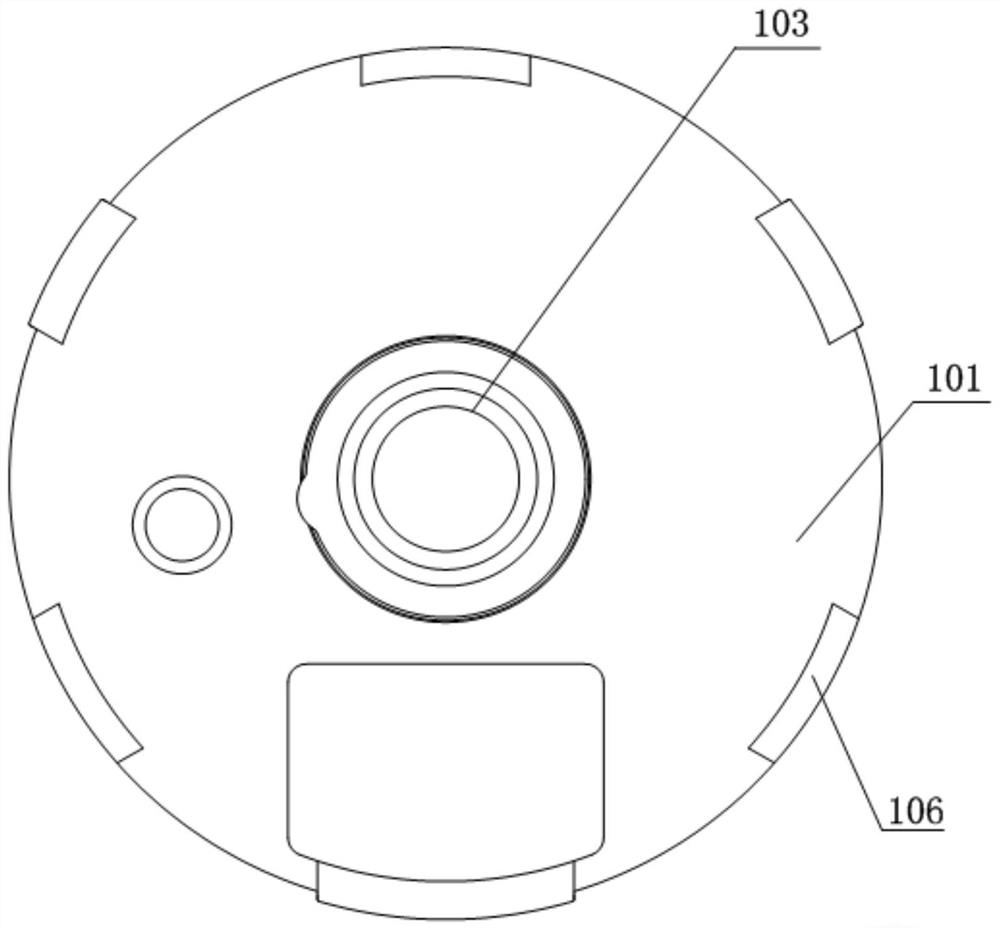

[0036] figure 1 It is a schematic structural diagram of the motor provided in Embodiment 1 of the present invention; figure 2 It is a sectional view of the motor provided by Embodiment 1 of the present invention. Such as figure 1 , 2 As shown, the motor provided by the embodiment of the present invention includes: a casing 9 and a stator and a rotor arranged in the casing 9 .

[0037] The motor type provided in this embodiment is an external rotor motor + a contact-proof casing. The stator includes: a stator core 7 , a coil 8 , a circuit board 2 and a bearing holder 1 ; the bearing holder 1 is fixed on a casing 9 . The stator core 7 and the coil 8 are arranged in cooperation, and the circuit board 2 is fixed on the inner side of the bearing holder 1 . The stator core 7 and the coil 8 are press-fitted with the bearing cage 1 for interference fit.

[0038] The rotor includes: a shaft 11 , a rotor frame 6 and a rotor magnet 5 . The shaft 11 passes through the casing 9 and...

Embodiment 2

[0045] This embodiment provides an electronic device, and the electronic device has the motor provided by any embodiment of the present invention. The electronic equipment includes, but is not limited to, refrigerators, washing machines, fans, air conditioners, clocks, and the like. The electronic equipment using the motor provided by any embodiment of the present invention can reduce the overall noise of the electronic equipment and prolong the service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com