Automatic production device for fruit and vegetable hot and sour rice noodles

A technology for making hot and sour powder of fruits and vegetables, which is applied in the direction of baking, dough extrusion machine, dough forming machinery or equipment, etc., which can solve the problem of increasing the workload of workers, easily scalding workers by boiling water steam, and cumbersome operation of hot and sour powder of fruits and vegetables and other issues, to achieve the effect of moderate length, reduce workload and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

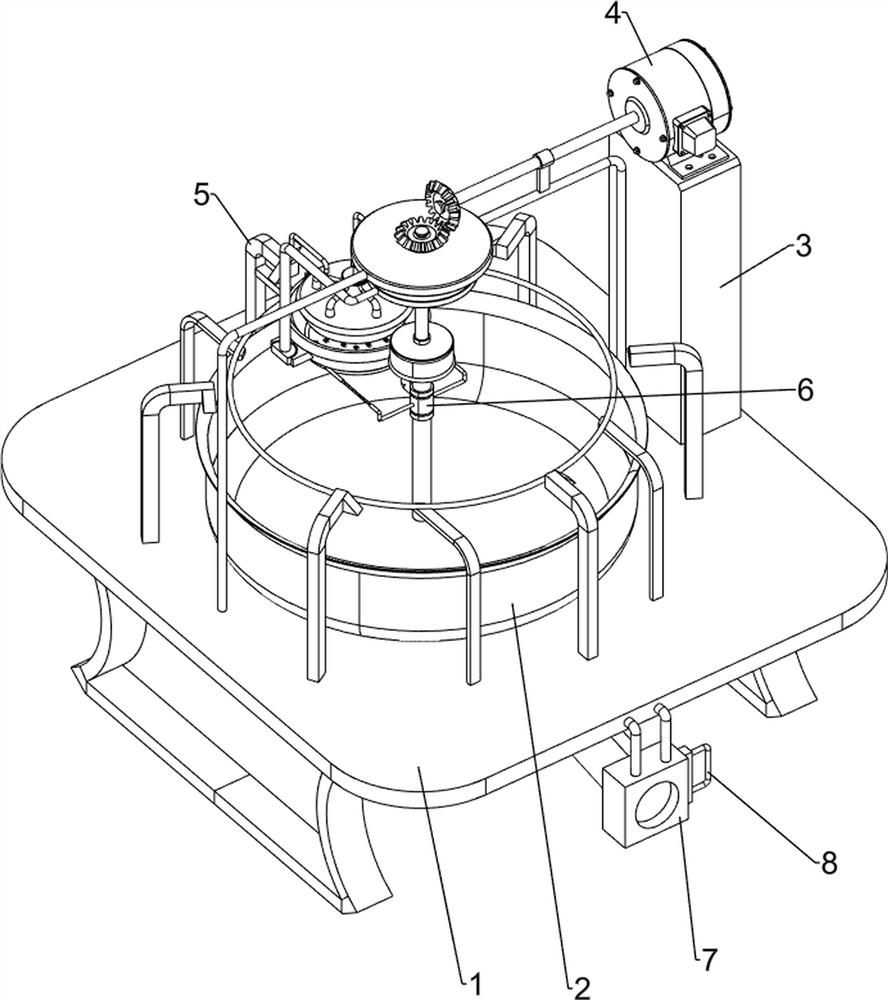

[0058] A kind of fruit and vegetable hot and sour powder automatic production device, such as figure 1 and figure 2 As shown, it includes a workbench 1, a water basin 2, a support platform 3, a rotating mechanism 4, and a beating mechanism 5. The middle side of the top of the workbench 1 is provided with a water basin 2, and the rear side of the top of the workbench 1 is provided with a support platform 3. , The supporting platform 3 is provided with a rotating mechanism 4, and the left side of the top of the workbench 1 is provided with a beating mechanism 5.

[0059] When using the present invention to make hot and sour noodles, first put the kneaded dough on the corresponding position of the rotary mechanism 4, then fill the water basin 2 with hot water, then open the rotary mechanism 4, and the rotary mechanism 4 rotates to drive Beating mechanism 5 pats the dough so that it falls into strips into the water holding basin 2 below. When it is not necessary to use the prese...

Embodiment 2

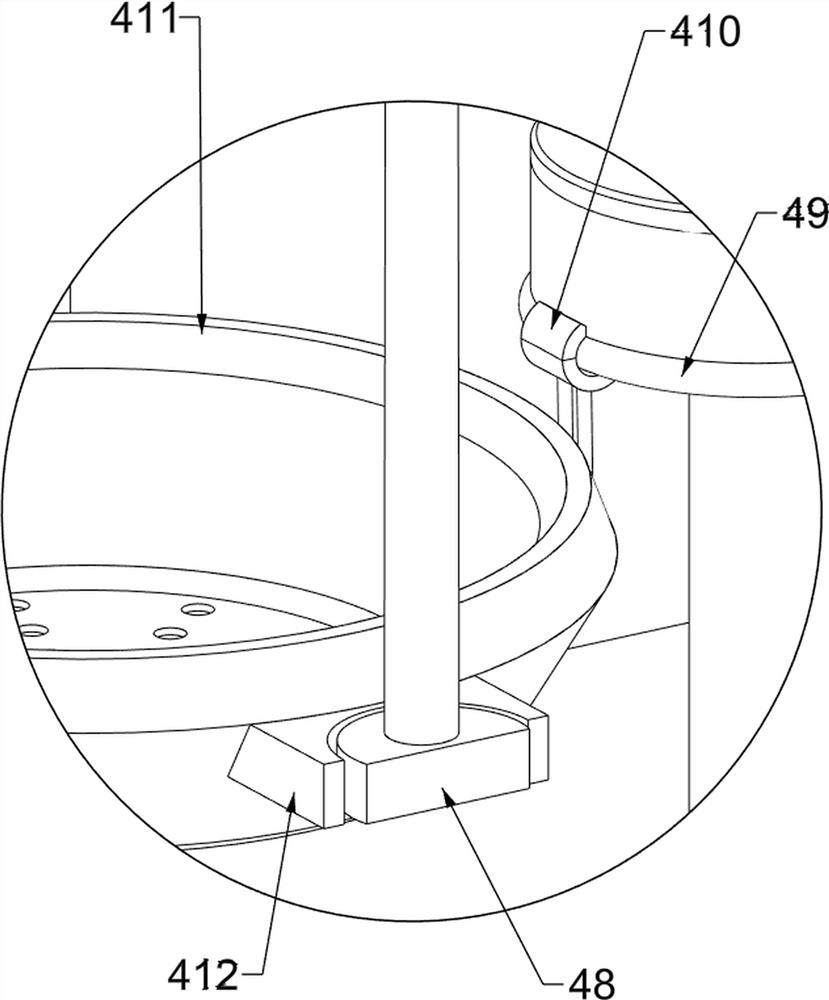

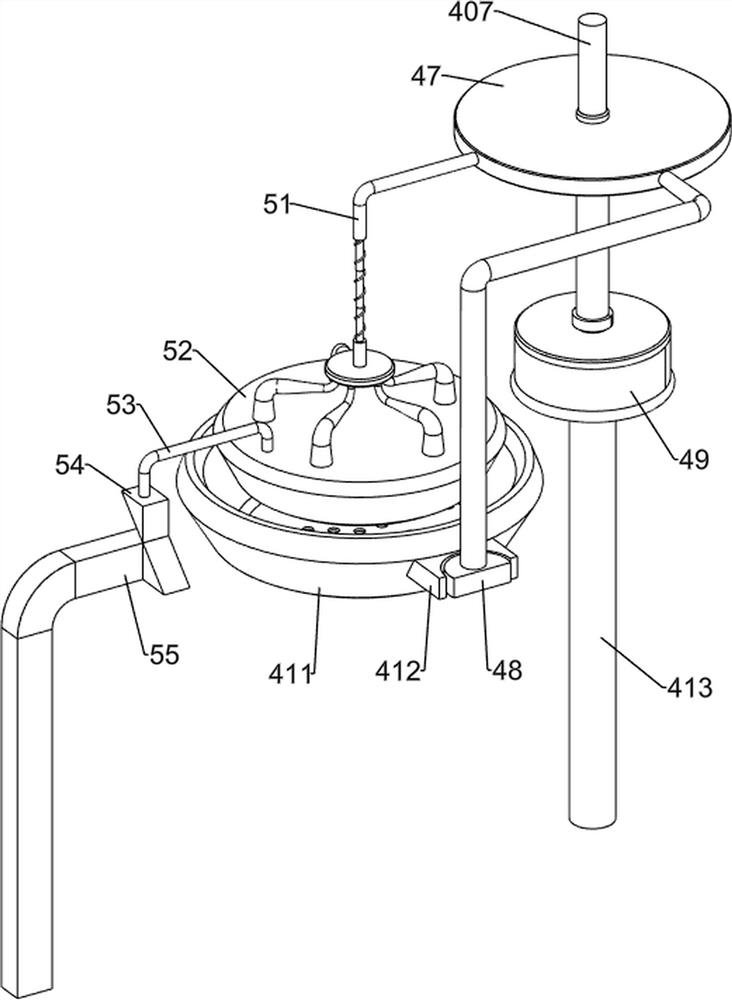

[0061] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 and Figure 5As shown, the rotary mechanism 4 includes a motor 41, a first rotating shaft 42, a bearing column 43, a first fixed column 44, a bevel gear 45, a first fixed plate 46, a rotating plate 47, a second rotating shaft 407, a push rod 48, The first circular slide rail 49, the first arc slide block 410, the discharge basin 411, the force plate 412, the second fixed column 413, the second arc slide block 414, the second circular slide rail 415 and the third Fixed column 416, motor 41 is installed on the support platform 3, the first fixed column 44 is all provided with the front and rear sides of the workbench 1 top, the first fixed column 44 on the rear side is positioned at the front of the support platform 3, the first fixed column on the rear side The upper side of the front part of 44 is provided with a bearing column 43, the output shaft of the motor 41 is provided with a first rotating sh...

Embodiment 3

[0066] On the basis of Example 2, such as figure 1 and Figure 5 As shown, it also includes a cutting mechanism 6, a discharge pipe 7 and a sliding baffle 8, the second fixed column 413 is provided with a cutting mechanism 6, and a discharge pipe 7 is arranged between the bottom and the right of the workbench 1, and the discharge Pipe 7 right part rear side sliding type is provided with sliding baffle plate 8.

[0067] In the process of beating the dough, the noodles extruded into strips fall into the water holding basin 2, and the discharge basin 411 rotates once, and the cutting mechanism 6 cuts the strips once, and pulls the sliding baffle 8 backward, and the strips Flow out from the discharge pipe 7, push the sliding baffle 8 forward, and the strips will no longer flow out from the discharge pipe 7.

[0068] The cutting mechanism 6 includes a second fixed plate 61, a third rotating shaft 62, a second telescopic assembly 63, a cutting plate 64, a right wedge 65, a left we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com