Method for emptying residual molten glass in platinum-rhodium crucible

A glass liquid and crucible technology, applied in the field of glass melting experimental processing equipment, can solve the problems of affecting the service life of platinum-rhodium crucibles, environmental pollution of hydrofluoric acid, damage to platinum-rhodium crucibles, etc. damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

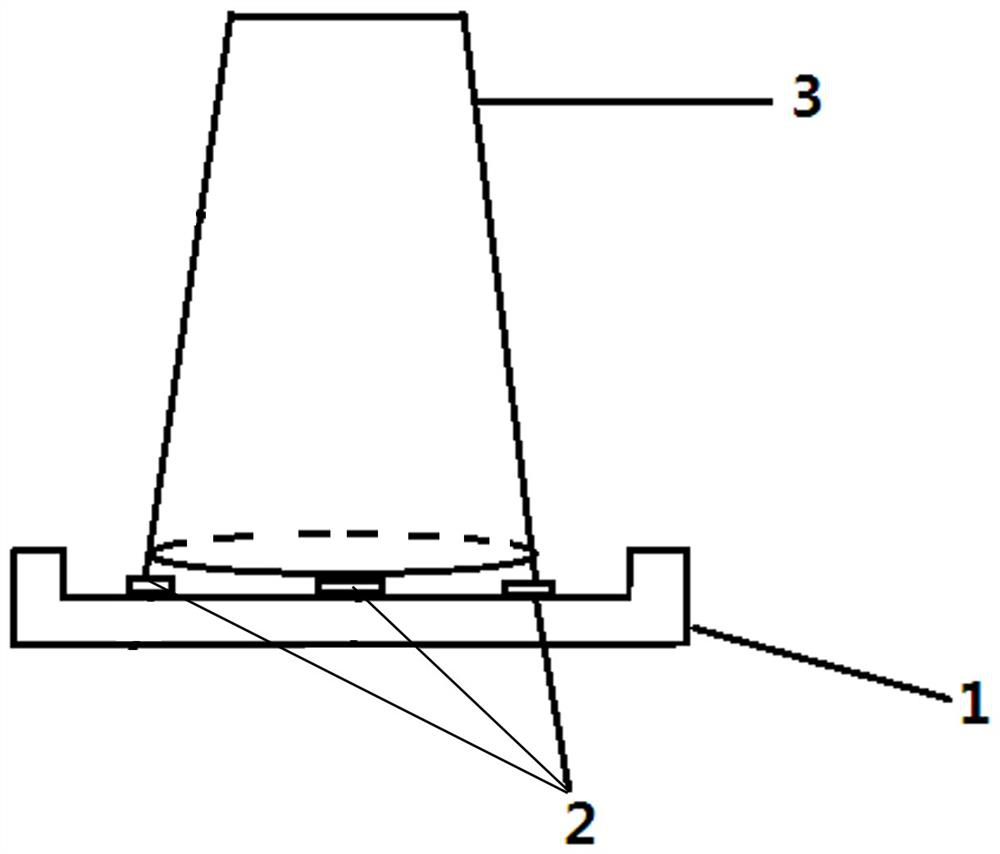

[0015] Such as figure 1 As shown, the invention provides a method for emptying the residual glass liquid of a platinum-rhodium crucible, comprising the following steps:

[0016] S1, take corundum tray 1;

[0017] S2. Place a group of corundum pads 2 in the corundum tray 1; when placing the corundum pads, arrange them according to the edge of the platinum-rhodium crucible;

[0018] S3, buckle the platinum-rhodium crucible 3 of the residual glass liquid upside down on the corundum pad 2, and the crucible edge of the platinum-rhodium crucible 3 cooperates with the corundum pad, so that the corundum pad forms a support for the platinum-rhodium crucible;

[0019] S4. Put the corundum tray and the platinum-rhodium crucible into a high temperature as a whole, and keep it at 1630° C. for 20 minutes, so that the residual glass liquid flows into the corundum tray 1 along the inner wall of the platinum-rhodium crucible 3 .

[0020] Afterwards, the platinum-rhodium crucible 3 is first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com