A beverage automatic canning equipment

An automatic and canning technology, applied in packaging, liquid bottling, transportation and packaging, etc., can solve the problem of bottle displacement and other problems, and achieve the effect of avoiding waste and preventing displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

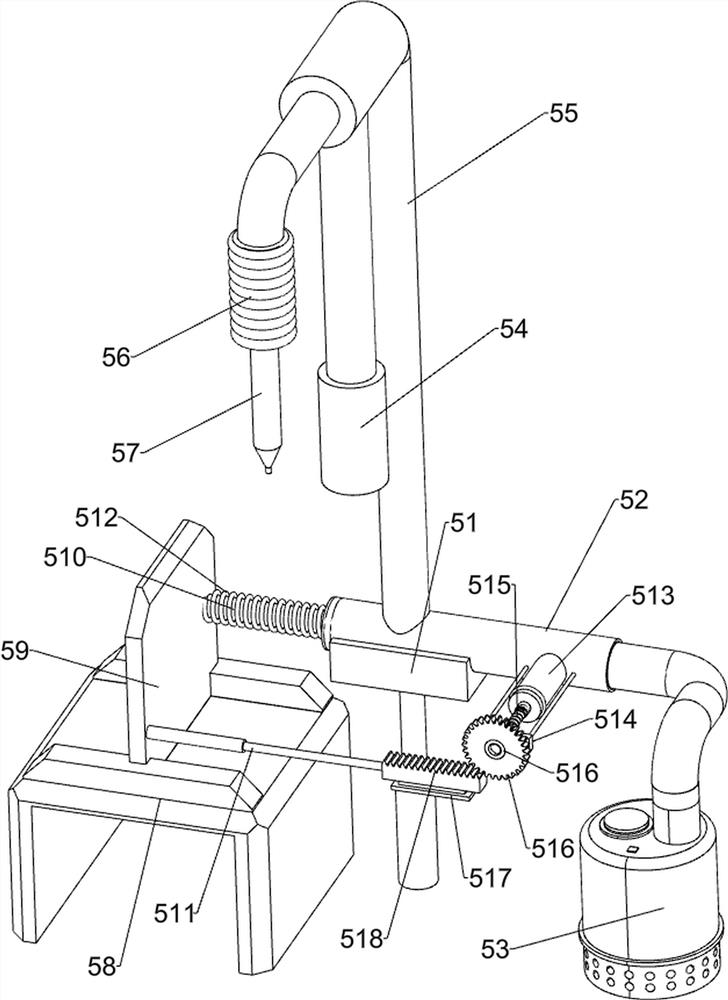

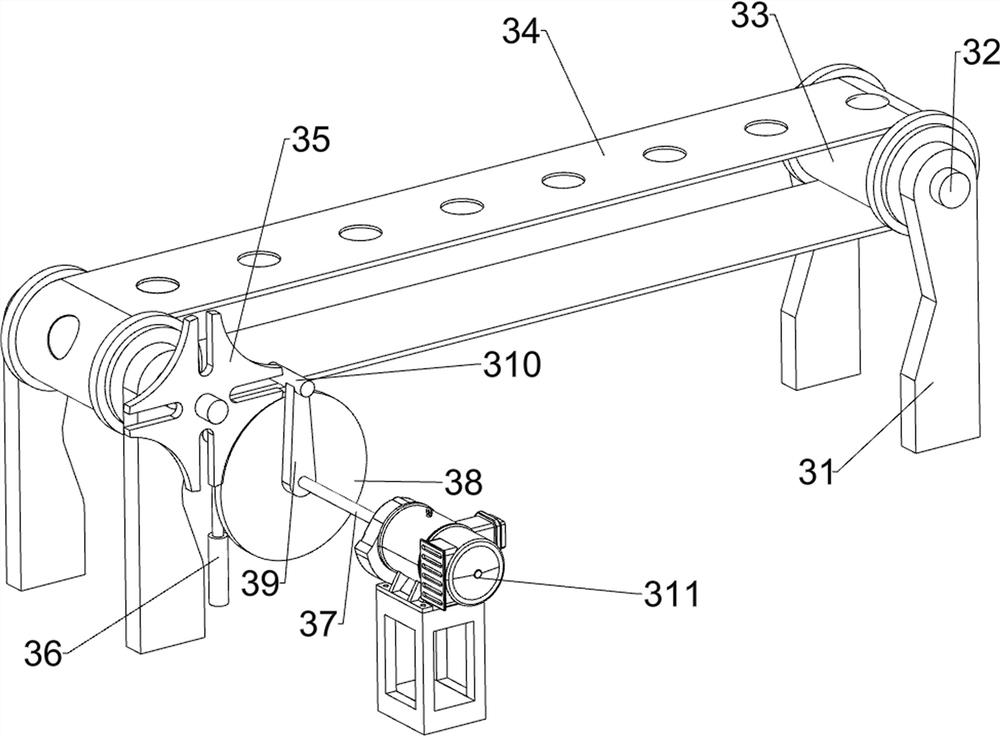

[0024] A beverage automatic canning equipment, such as Figure 1-4 As shown, it includes a base 1, a worktable 2, a feeding device 3, a canned box 4, an opening and closing device 5 and a lifting device 6, the top of the base 1 is provided with a workbench 2, the top of the base 1 is provided with a feeding device 3, and the base 1 A canned box 4 is arranged on the left side of the top, a square groove is opened on the right front side of the top of the canned box 4, an opening and closing device 5 is arranged on the top of the base 1, and a lifting device 6 is arranged on the workbench 2.

[0025] When people need to use this equipment, first people place the bottle on the feeding device 3, and pour the beverage into the canning box 4, then the opening and closing device 5 and the feeding device 3 can be started, so that the opening and closing device 5 and the feeding device The device 3 operates, so that the feeding device 3 drives the lifting device 6 to operate, and the f...

Embodiment 2

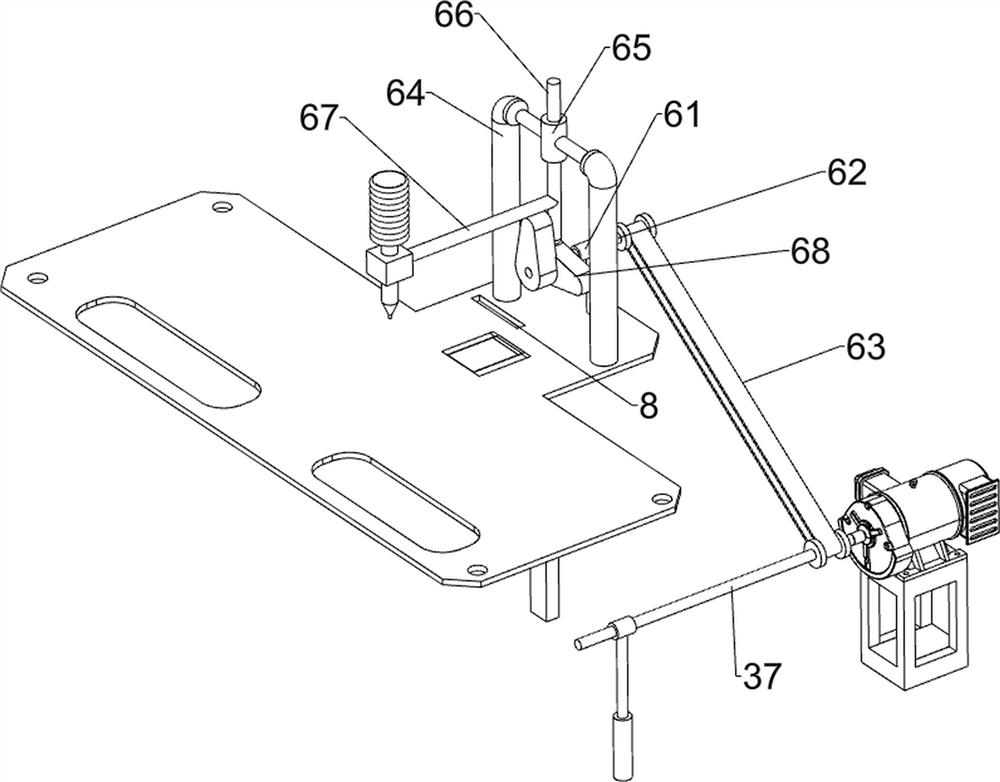

[0033] On the basis of Example 1, such as Figure 5 and Figure 6 As shown, it also includes a guide sleeve 7, an L-shaped frame 9, a third connecting rod 10, and a second cam 11. The rear side of the top of the base 1 is provided with a guide sleeve 7, and the rear side of the workbench 2 has a square hole 8. The guide sleeve 7. The upper sliding type is provided with an L-shaped frame 9, and the L-shaped frame 9 slides on the square hole 8 of the workbench 2. The right end of the L-shaped frame 9 is provided with a third connecting rod 10, and the third connecting rod 10 and the first slide block 59 The rear side is connected, the rotating rod 62 is provided with a second cam 11, the second cam 11 cooperates with the L-shaped frame 9, and the second cam 11 is located at the front side of the first cam 68.

[0034] When the rotating rod 62 rotates, the rotating rod 62 drives the second cam 11 to rotate, and when the most convex part of the first cam 68 contacts the slide bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com