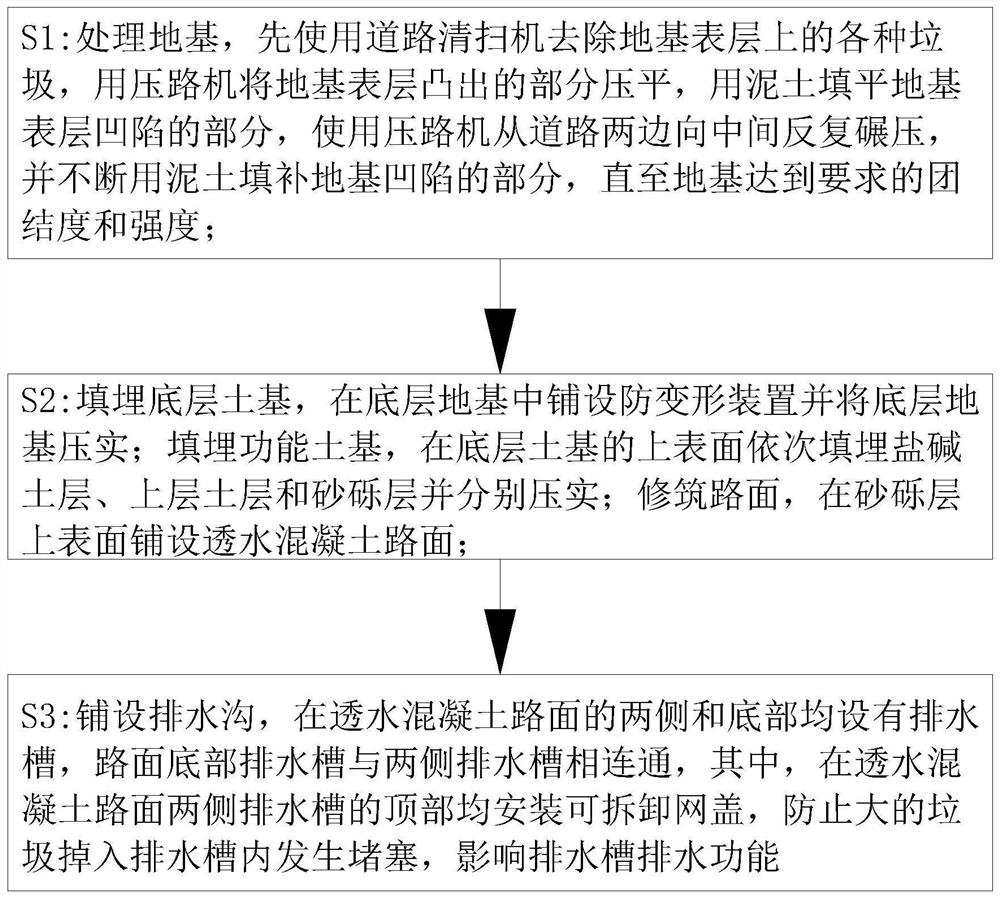

Municipal roadbed construction method

A construction method and subgrade technology, applied in the direction of roads, roads, road surface cleaning, etc., can solve the problems of insufficient strength of cleaning blades, easy to break of cleaning blades, etc., to reduce the probability of damage and improve the strength and torque bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

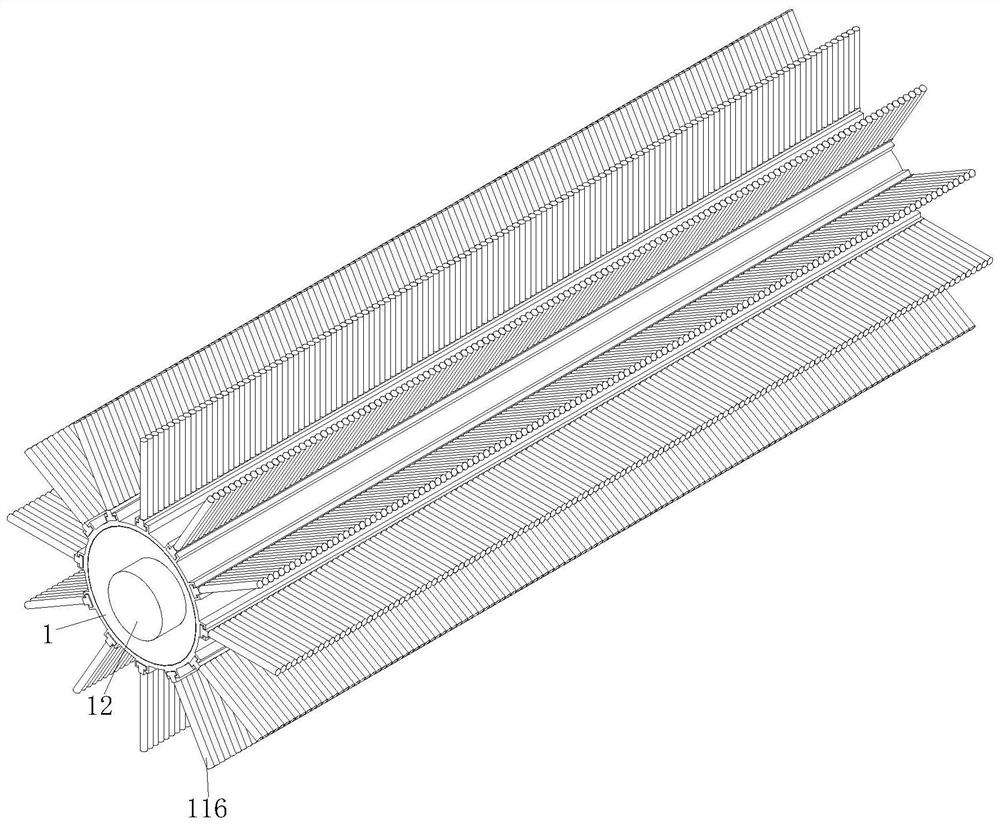

[0036] As a specific embodiment of the present invention, the rotating plate 111 is composed of several hollow tubes 116 and a T-shaped block 117; several hollow tubes 116 are fixed side by side on the bottom of the T-shaped block 117; the hollow tubes 116 have free ports. There is a leaking net 118 to prevent larger particles of rubbish from entering the hollow tube 116; during use, when the cross-sectional area and length are all the same, the solid rod is made into a hollow tube 116 with an internal and external diameter of 8:11, which can effectively improve the hollow tube. The intensity of 116, the hollow tube 116 that is arranged side by side forms rotating plate 111, has improved the torsional moment bearing capacity of rotating plate 111 on the one hand, has improved the strength of rotating plate 111, and on the other hand hollow tube 116 that is arranged side by side forms rotating plate 111, When the rotating plate 111 is damaged, it is only necessary to replace the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com