Pre-lithiated material and preparation thereof, precursor material, lithium battery negative electrode slurry and lithium battery

A technology of negative electrode slurry and pre-lithiation, which is applied to battery electrodes, secondary batteries, circuits, etc., to achieve high overall process safety and solve complex process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

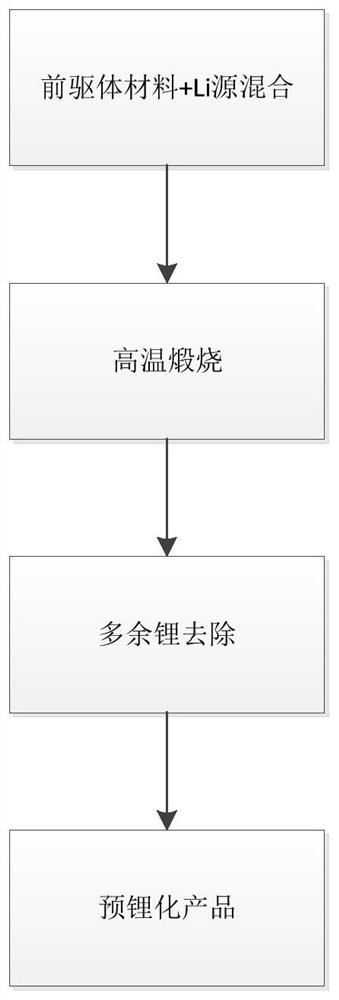

Method used

Image

Examples

Embodiment 1

[0079] Embodiment 1 Precursor material shell material test

[0080] Precursor material: Si is the core, the core size is 200nm, and the shell size is 100nm. Different shell materials are selected respectively, and the corresponding pre-lithiated materials are prepared according to the pre-lithiated material preparation process recorded in Experiment 1. According to Experiment 2 The shell performance test process of the precursor described in , tests each shell material, and the results are as follows (see Table 1).

[0081] Table 1

[0082]

[0083]

[0084] Only materials with a low lithium ion diffusion coefficient at room temperature and a sharp change in the lithium ion diffusion coefficient under high temperature or high potential conditions can become a protective shell material. In this way, lithium ions cannot escape after the material is prepared. At the same time, we also examined the strength of the shell, because the core will expand to a certain extent aft...

Embodiment 2

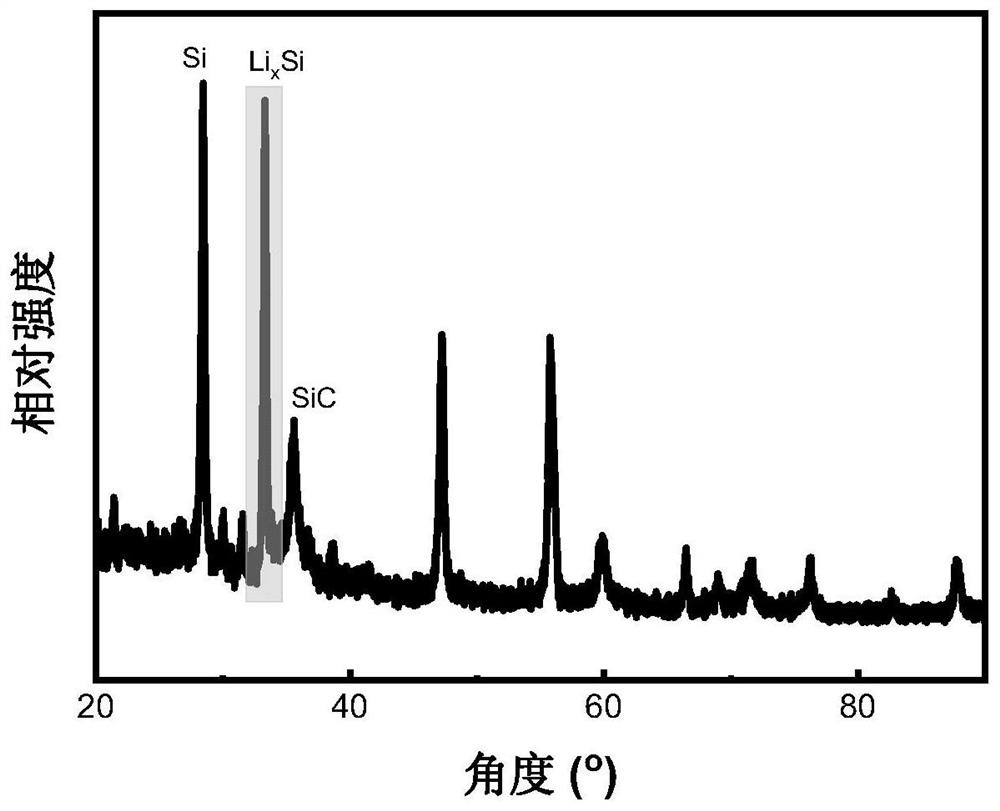

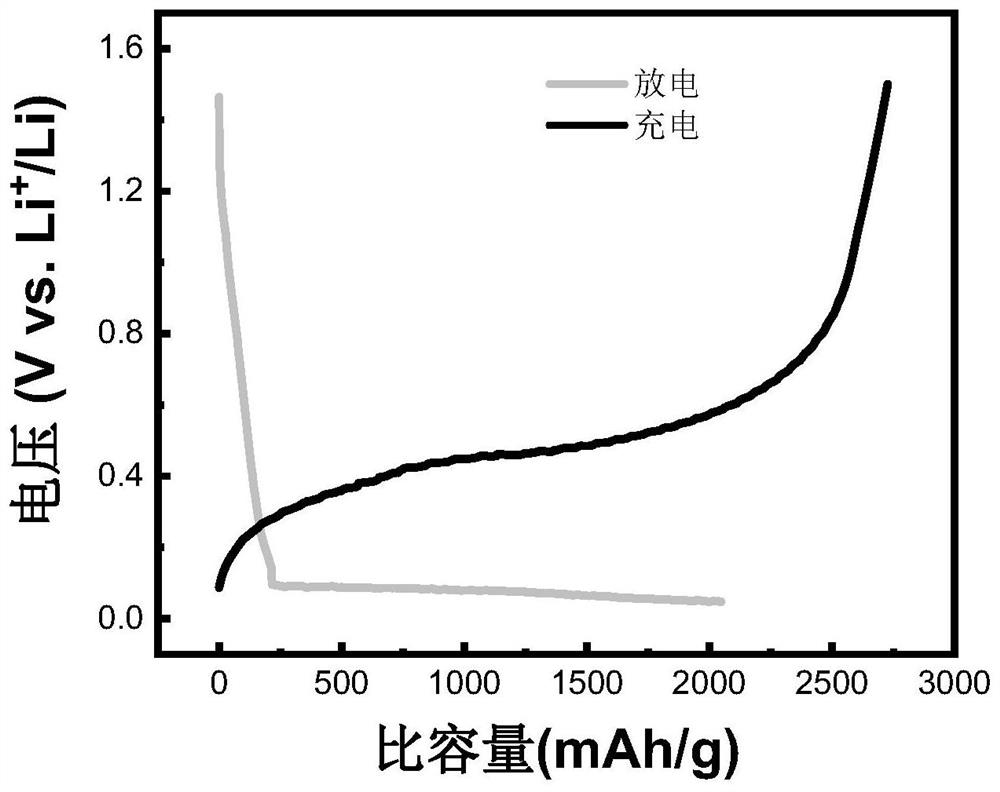

[0088] Example 2 Precursor material core material test

[0089] Precursor material: the core size is 200nm, the shell size is 100nm, the shell material is SiC, the selection of the core material is shown in Table 2, and the corresponding pre-lithiation material is prepared according to the pre-lithiation material preparation process recorded in Experiment 1, according to The pre-lithiation material performance test process described in Experiment 3 tested different core materials, and the results are as follows (see Table 2).

[0090] Table 2

[0091] Si@SiC S@SiC Fe@SiC W@SiC Sn@SiC Hollow@SiC Discharge capacitymAh / g 2689 1234 567 431 987 300 Delithiation potential V 0.41 1.8 1.2 1.4 0.8 0 Charging capacitymAh / g 2890 1349 786 543 1026 680 First cycle Coulombic efficiency% 107 109 138 126 104 227

[0092] According to the test results in Table 2, it can be seen that selecting a suitable shell can enable lit...

Embodiment 3

[0095] Example 3 Precursor material core / shell size test

[0096] Precursor material: the core material is Si, the shell material is SiC, the size selection of the core and the shell is shown in Table 3, and the corresponding pre-lithiated material is prepared according to the pre-lithiated material preparation process recorded in Experiment 1, and the experiment is carried out according to Experiment 2 The performance test results corresponding to the core and shell sizes are as follows (see Table 3).

[0097] table 3

[0098] 1 2 3 4 5 6 kernel size 10um 10um 10um 10um 10um 10um shell thickness 2nm 50nm 500nm 20um 50um 100um Discharge capacitymAh / g 856 832 810 730 540 430 7 8 9 10 11 12 kernel size 2nm 50nm 500nm 20um 50um 100um shell thickness 10um 10um 10um 10um 10um 10um Test Results 143 324 432 543 632 870

[0099] According to the test results in Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com