Stainless steel fan with gas purification function

A gas purification and stainless steel technology, which is applied to liquid fuel engines, parts of pumping devices for elastic fluids, mechanical equipment, etc., can solve the problems of inconvenient installation and maintenance, inconvenient installation, and inability to purify gas, etc., and achieve improvement Working environment, easy installation and disassembly, and convenient storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

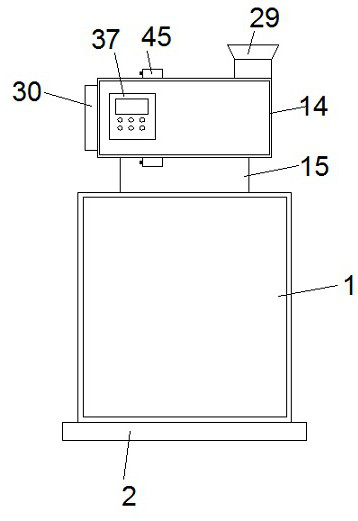

[0033]SeeFigure 1-9According to an embodiment of the present invention, a stainless steel fan with gas purification function includes a receiving cavity 1, a mounting seat 2 is fixed at the bottom of the receiving cavity 1, and a screw 3 and Screw two 4, the threads on the screw one 3 and the screw two 4 are reverse threads, the screw one 3 and the screw two 4 are connected by a coupling 5, and the screw one 3 is far away One end of the coupling 5 is connected to the output end of the motor 6, the motor 6 is fixedly installed on the inner wall of the receiving cavity 1, and the end of the screw rod 4 away from the coupling 5 penetrates through the bearing One 7 extends into the bearing one 7, the outer sides of the screw one 3 and the two screw 4 are threadedly connected with a sliding block 8, and the surface of the sliding block 8 is fixed with a movable shaft, the movable shaft One is sleeved with a support frame 9, one end of the support frame 9 away from the movable shaft is sl...

Embodiment 2

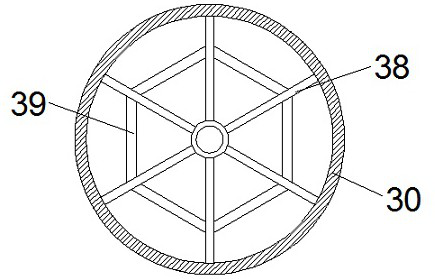

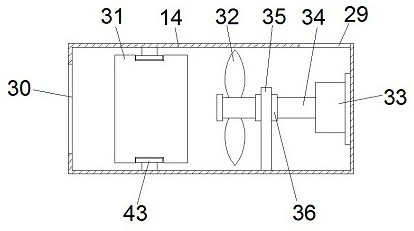

[0036]SeeFigure 1-9For the air inlet 30, a dust filter plate 38 is installed at the air inlet 30, and reinforcing ribs 39 are fixed between the dust filter plates 38. For the control box 37, a display screen and an operation button are installed on the control box 37, and the display screen is electrically connected to the operation button.

[0037]Through the above-mentioned solution of the present invention, the beneficial effect is: by providing the dust filter plate 38, the foreign matter with large particles can be blocked from the air inlet 30, and the stainless steel fan can be protected; the display screen and the operation button are convenient Manual adjustment control.

Embodiment 3

[0039]SeeFigure 1-9For the filter cartridge 31, a first filter screen layer 40, a second filter screen layer 41 and an activated carbon adsorption layer 42 are fixedly installed inside the filter cartridge 31 in sequence.

[0040]Through the above-mentioned solution of the present invention, the beneficial effect is that by providing the first filter mesh layer 40, the second filter mesh layer 41 and the activated carbon adsorption layer 42 for layer-by-layer filtration and adsorption, the filtration effect is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com