Magnetic liquid damping shock absorber based on first-order and second-order buoyancy principles

A magnetic liquid, second-order buoyancy technology, used in shock absorbers, friction shock absorbers, shock absorbers, etc., can solve the problems of slow movement of permanent magnets, radial disturbances, easy collision with shell walls, etc., to improve efficiency and Vibration reduction effect, excellent vibration reduction effect, flexible movement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

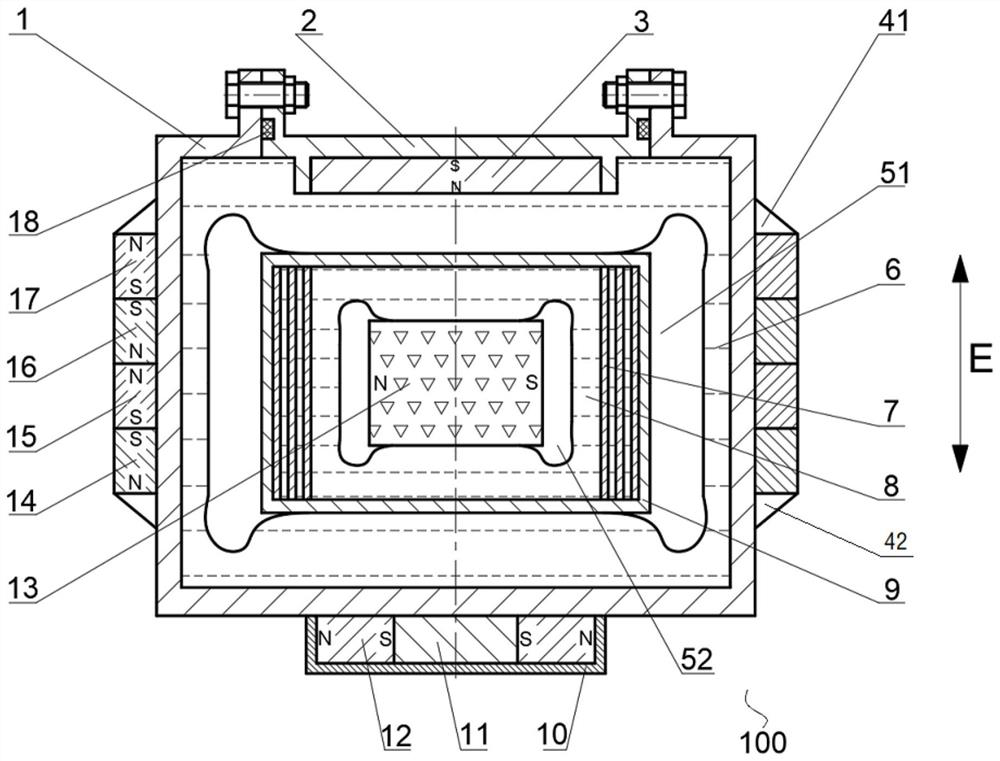

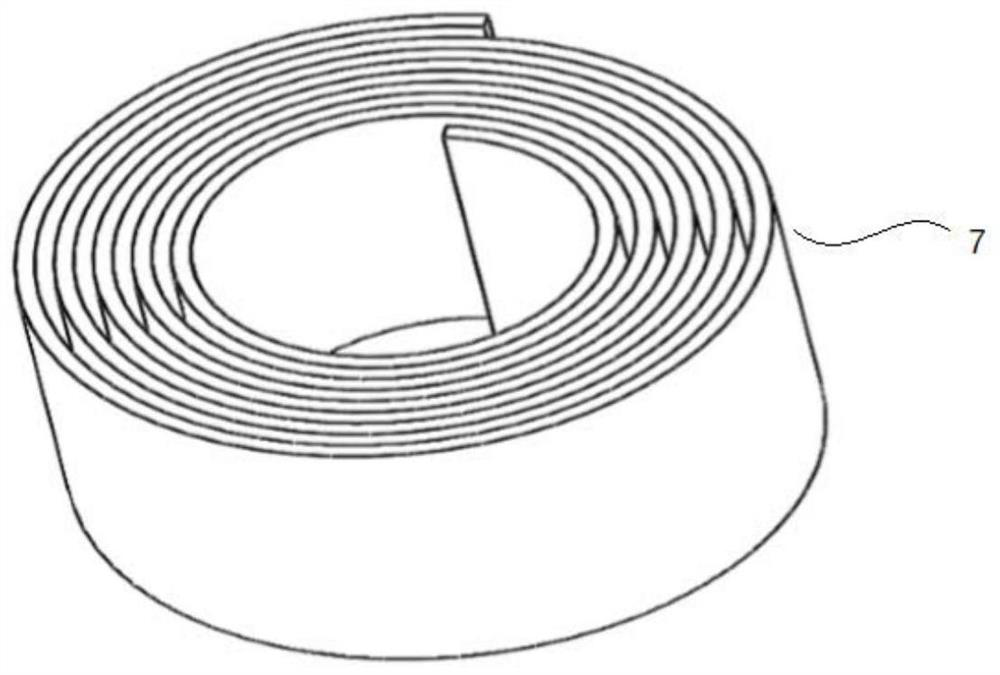

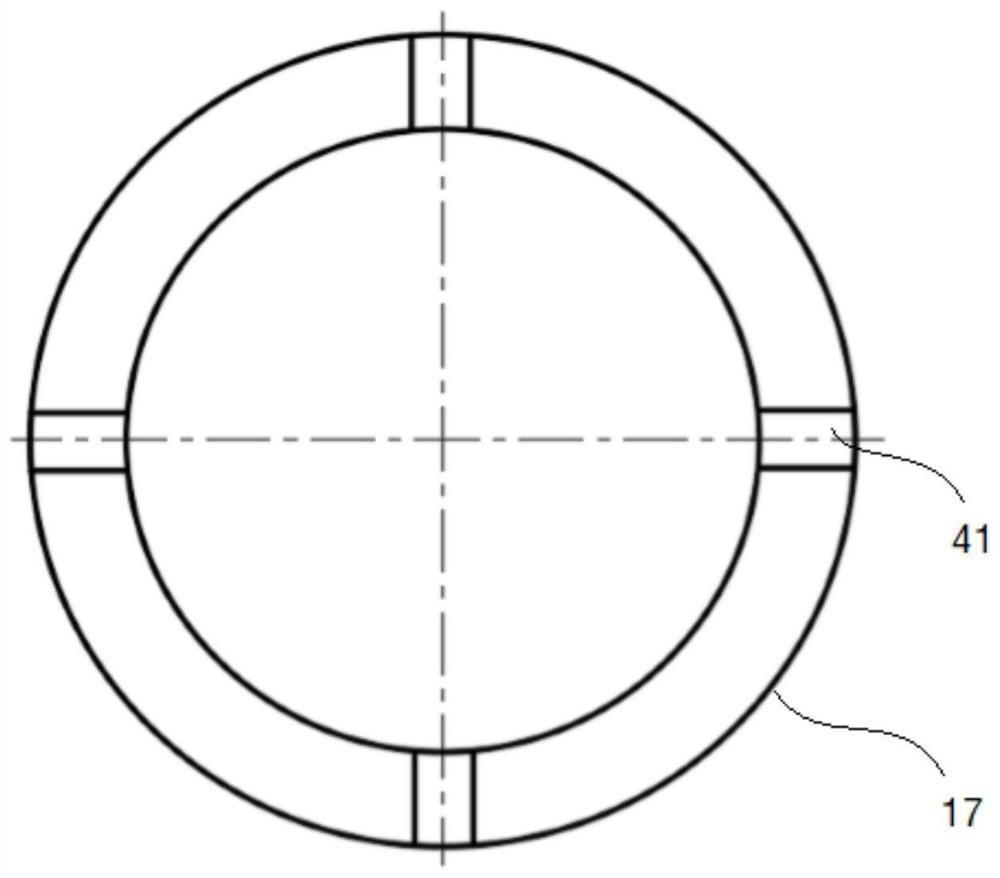

[0027] Refer below Figure 1 to Figure 4 The magnetic liquid damping shock absorber 100 based on the first-order and second-order buoyancy principles according to an embodiment of the present invention will be described.

[0028] Such as figure 1 As shown, the magnetic liquid damping shock absorber 100 according to the embodiment of the present invention includes a housing, a first permanent magnet 3, a second permanent magnet 12, a non-magnetic shell 9, a suspension permanent magnet 13, a first magnetic liquid 6 and a second permanent magnet. Two magnetic liquids8.

[0029] The housing defines a first closed cavity. Both the first permanent magnet 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com