Logistics node layout optimization method and system based on agricultural product cold-chain logistics requirements

A technology of cold chain logistics and agricultural products, applied in logistics, neural learning methods, biological neural network models, etc., can solve inaccurate prediction results, failure to meet the agricultural product market, and scientific and reasonable solution to the logistics node selection of agricultural product cold chain logistics The location problem logistics node scale optimization problem and other problems, to achieve the effect of solving the location problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a logistics node layout optimization method based on agricultural product cold chain logistics requirements;

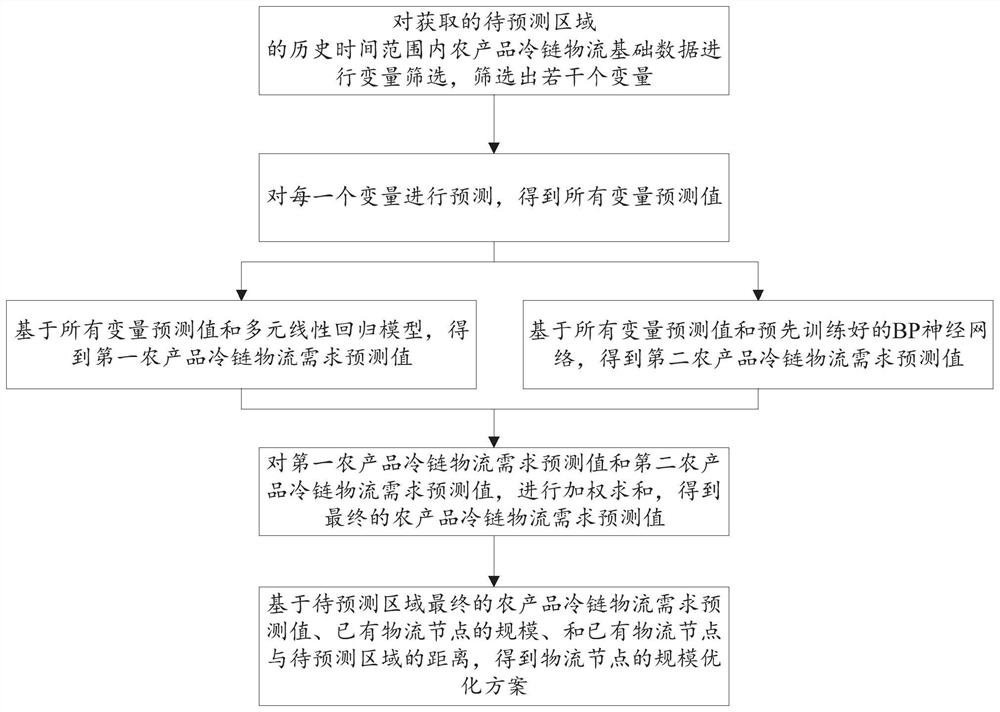

[0032] like figure 1 As shown, the logistics node layout optimization method based on the cold chain logistics demand of agricultural products includes:

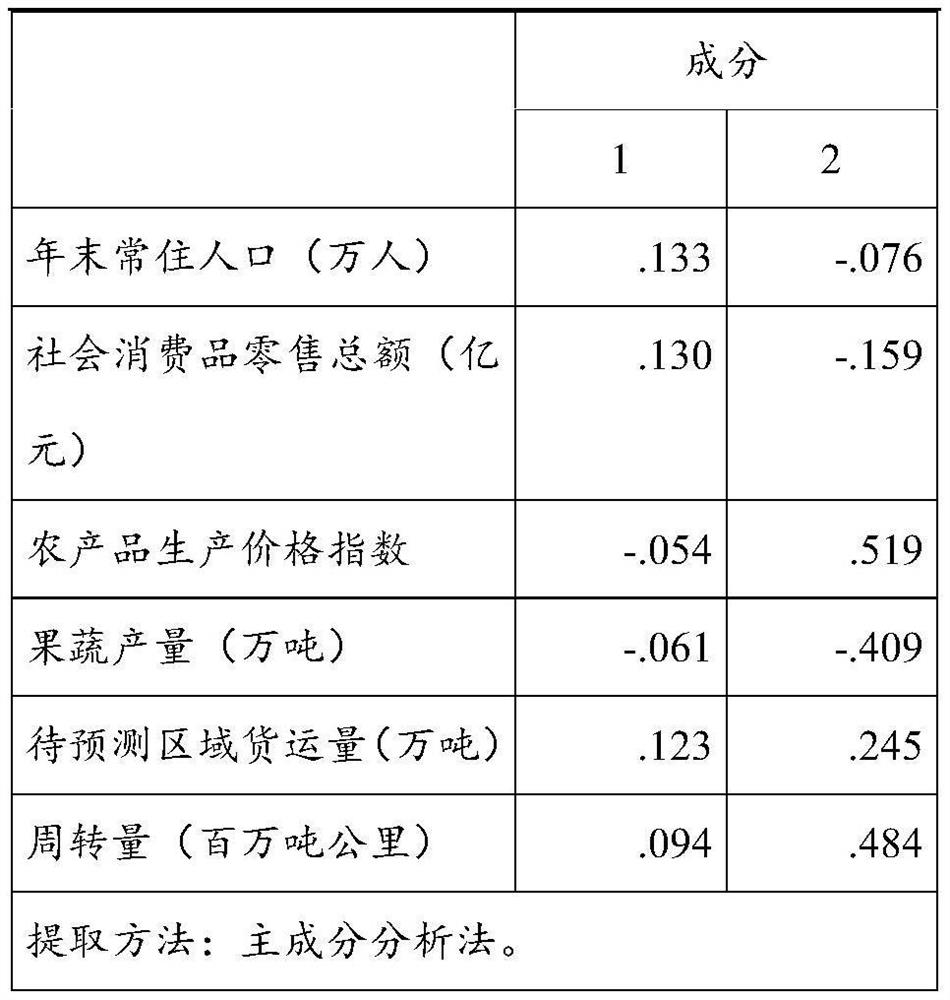

[0033] S101: Perform variable screening on the obtained basic data of agricultural product cold chain logistics in the historical time range of the region to be predicted, and select several variables;

[0034] S102: Predict each variable to obtain predicted values of all variables;

[0035] S103: Based on the predicted values of all variables and the multiple linear regression model, obtain the predicted value of the first agricultural product cold chain logistics demand;

[0036] Based on the predicted values of all variables and the pre-trained BP neural network, the predicted value of the second agricultural product cold chain logistics demand is obtained;

[0037] S104: ...

Embodiment 2

[0114] This embodiment provides a logistics node layout optimization system based on agricultural product cold chain logistics requirements;

[0115] Logistics node layout optimization system based on agricultural product cold chain logistics demand, including:

[0116] The variable screening module is configured to: perform variable screening on the acquired agricultural product cold chain logistics basic data within the historical time range of the area to be predicted, and select several variables;

[0117] A variable prediction module configured to: predict each variable to obtain predicted values of all variables;

[0118] The demand prediction module is configured to: obtain the first agricultural product cold chain logistics demand prediction value based on all variable prediction values and multiple linear regression models; obtain the second agricultural product cold chain logistics demand prediction value based on all variable prediction values and a pre-traine...

Embodiment 3

[0125] This embodiment also provides an electronic device, including: one or more processors, one or more memories, and one or more computer programs; wherein, the processor is connected to the memory, and the one or more computer programs are programmed Stored in the memory, when the electronic device is running, the processor executes one or more computer programs stored in the memory, so that the electronic device executes the method described in Embodiment 1 above.

[0126] It should be understood that in this embodiment, the processor can be a central processing unit CPU, and the processor can also be other general-purpose processors, digital signal processors DSP, application specific integrated circuits ASIC, off-the-shelf programmable gate array FPGA or other programmable logic devices , discrete gate or transistor logic devices, discrete hardware components, etc. A general-purpose processor may be a microprocessor, or the processor may be any conventional processor, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com