Vehicle system module display platform control system and maintenance method

A vehicle system and display platform technology, applied in the field of vehicle system module display platform control system and maintenance, can solve the problems of CAN line failure of the body control unit, inability to integrate theory and practice, combination switch failure, etc., to achieve enhanced Cognitive, contact clear and practical, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0120]The present invention will be described in detail below with reference to the drawings and embodiments:

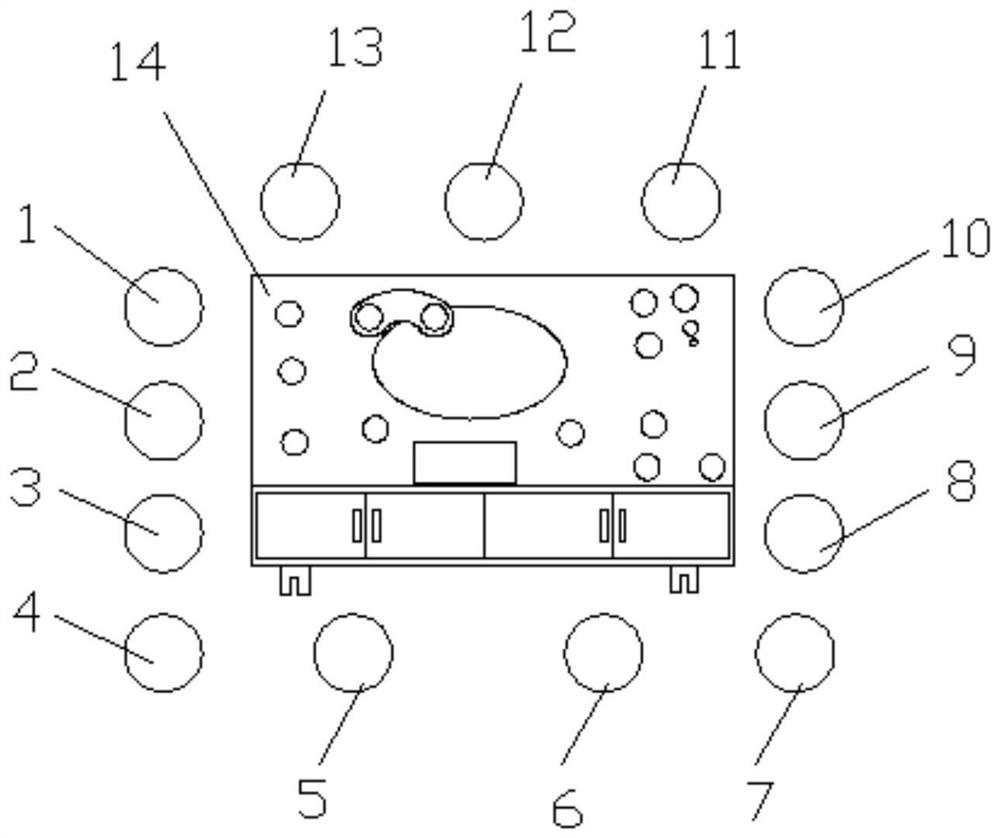

[0121]Attachedfigure 1It can be seen that a vehicle system module display platform includes a support structure, a display panel, and a fault setting system. The support structure includes a film formed by electrostatic spraying on the surface, heated and melted and solidified, and a platform spliced by a dedicated T-bolt internal connection method. The overall structure of the frame and silent casters;

[0122]The display panel is installed in-line;

[0123]The fault setting system includes a fault detection box, a dedicated patch cord and a fault setting device.

[0124]The support structure is designed with a metal structure, and the display panel is equipped with an external test hole and is attached with a painted circuit diagram and a measuring hole, and the system circuit link diagram.

[0125]The colored drawing circuit diagram adopts heat-fixable resin impregnated paper high-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com