Fixed-depth precise thermal remediation method and device

A thermal remediation and precise technology, applied in the restoration of polluted soil and other directions, can solve the problems of high cost and high energy consumption, and achieve the effect of reducing the volume of heating soil, reducing heating energy consumption and remediation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention provides a fixed-depth precise thermal repair method, comprising the following steps:

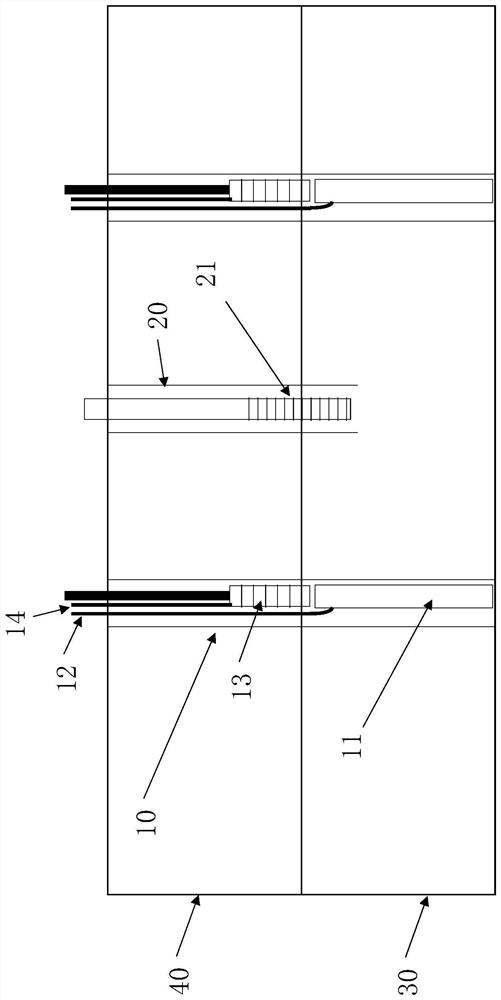

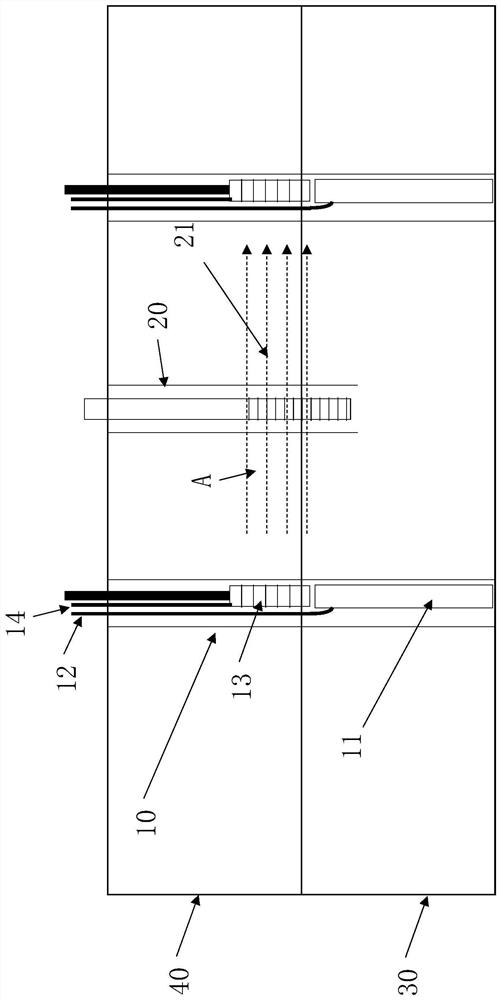

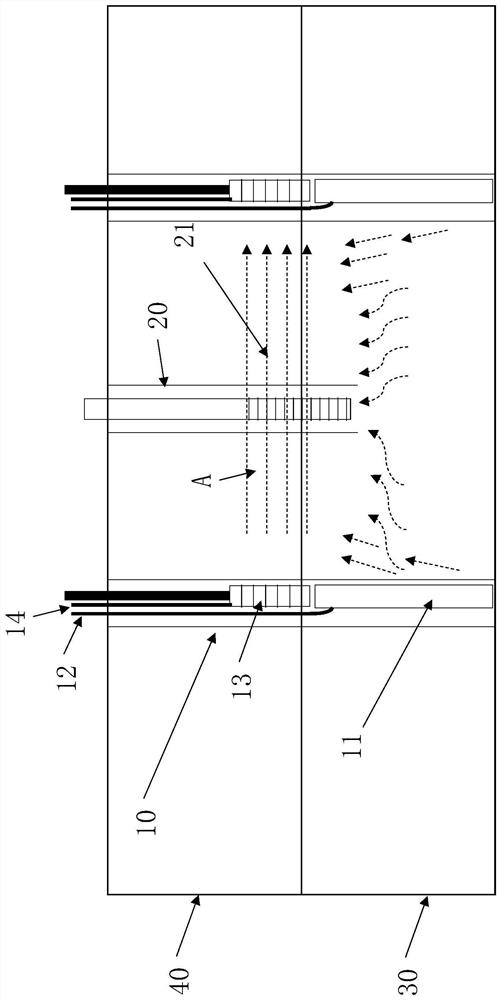

[0033] Such as figure 1 As shown, multifunctional wells 10 and extraction wells 20 are arranged in the polluted area, wherein:

[0034] An electric heating device 11 is arranged in the area corresponding to the polluted formation 30 in the multifunctional well 10, and the electric heating device 11 is connected with an AC cable 12; wherein, the electric heating device 11 can be an electrode to realize resistance Heating (maximum heating temperature below 100°C), or a heating rod to achieve heat conduction heating (maximum heating temperature can be higher than 100°C), so as to meet different heating temperature requirements;

[0035] In the multifunctional well 10, the area corresponding to the clean formation 40 is provided with a drug injection pipe 13, and the surface of the drug injection pipe 13 is provided with a drug injection screen slit 14 (about 1 mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com