Laser shot peening strengthening-shape correcting method for annular part and integrated device thereof

A technology of laser shot peening and ring parts, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of cumbersome clamping, limited objects and scope, not suitable for mass production, etc., to improve accuracy High precision, accuracy and practicability, reducing the effect of manpower waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

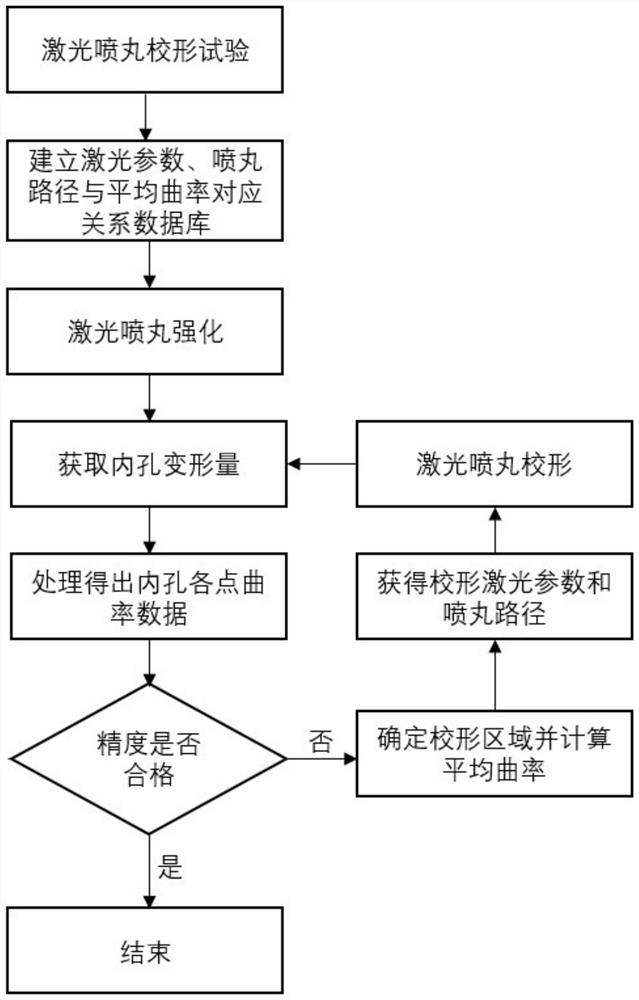

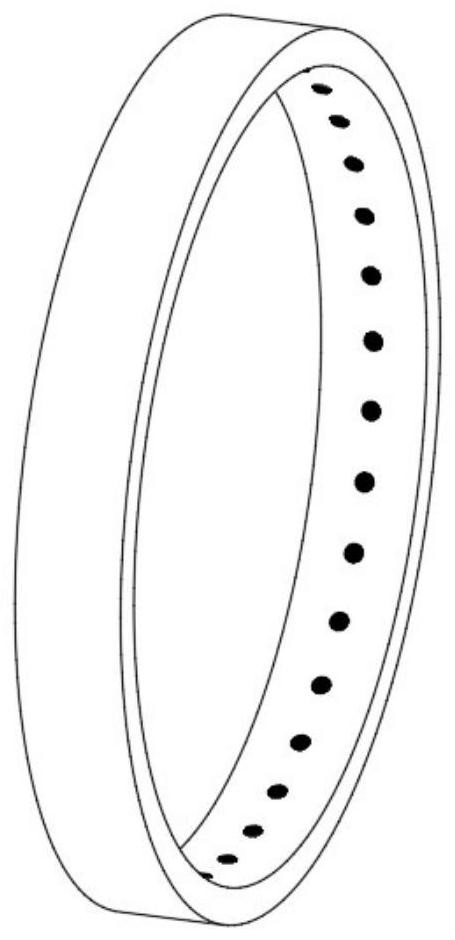

[0039] Such as figure 1 As shown, the laser shot peening strengthening-shaping method for annular parts of the present invention comprises the following steps:

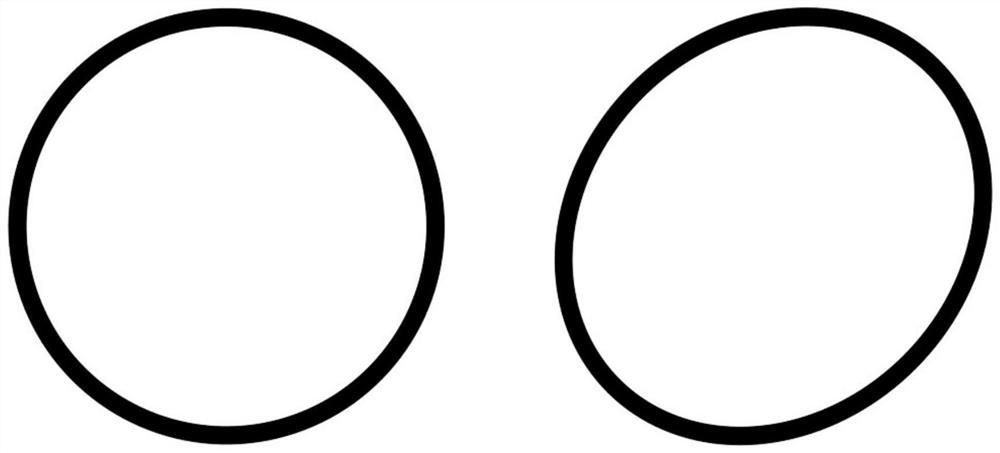

[0040] Step 1: Obtain the average curvature change data of the shape correction area through the laser shot peening shape correction test, and establish a database corresponding to the laser parameters, shot peening path and average curvature; the laser parameters and shot peening path are suitable for the shape correction requirements of ring parts ;

[0041] Step 2: Select laser parameters according to the strengthening requirements of the residual compressive stress of the ring part for shot peening. At the same time, the industrial camera 9 detects the deformation of the inner hole after shot peening and tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com