Electric tool with separable working head with intelligent identification

An intelligent identification, power tool technology, applied in the direction of manufacturing tools, portable mobile devices, etc., can solve the problems of increasing consumer costs, damage to work heads, material waste, etc., to achieve good fixing effects, reduce costs, and ensure continuous use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

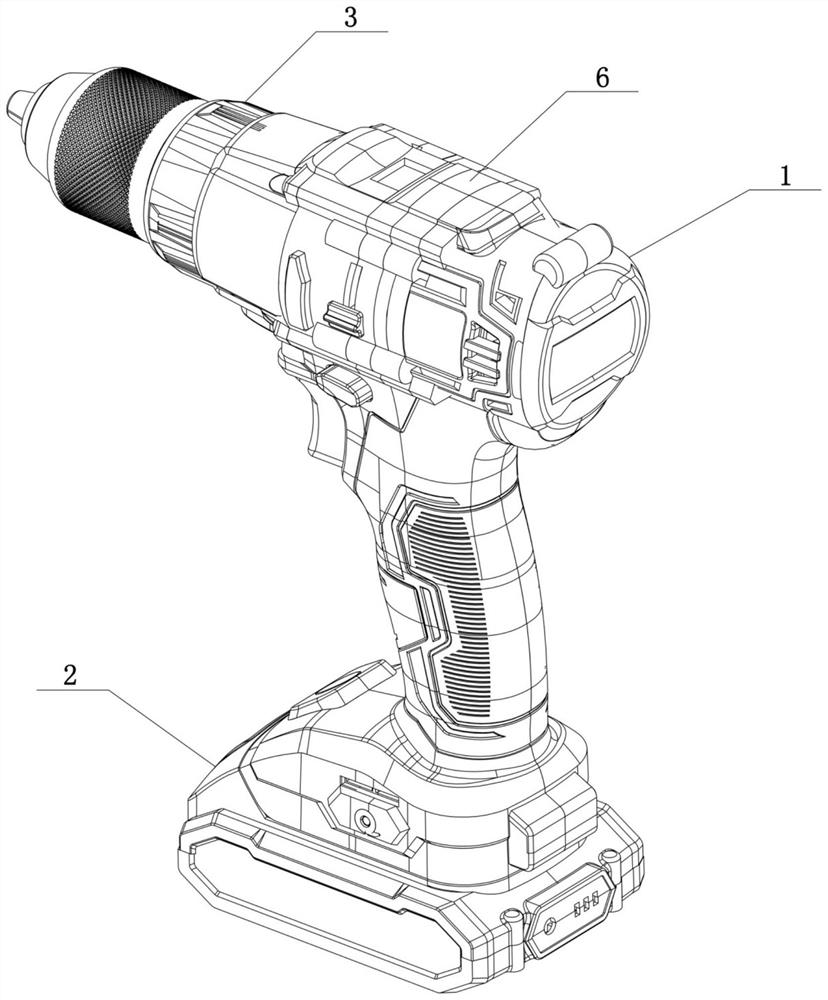

[0054] Such as figure 1 , figure 2 , Figure 5 to Figure 13 As shown, an electric tool with a detachable working head is mainly aimed at occasions where the work cannot be carried out due to damage to the working head 5 and the whole machine needs to be replaced urgently, or where different types of tools are required due to the diversification of the work. In the case of electric tools.

[0055] It includes: a driving handle 1, a power supply part 2 for power supply on the driving handle 1, and a controller 3 for command processing;

[0056] The controller 3 includes a single-chip microcomputer. The single-chip microcomputer has the characteristics of high integration, small size, good reliability, rich instructions, and strong control ability, and can well assist the electric tool of this technical solution to realize the following functions.

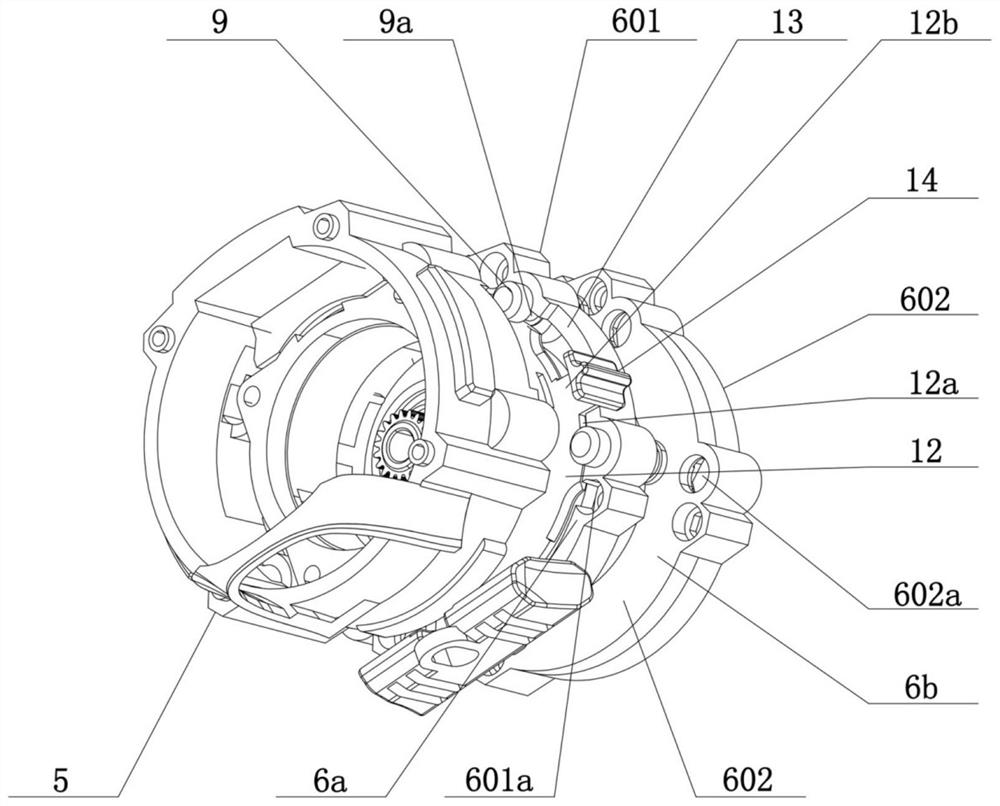

[0057] It also includes: motor 4, working head 5, assembly and disassembly assembly 6, sensed element 7 and sensing element 8, b...

Embodiment 2

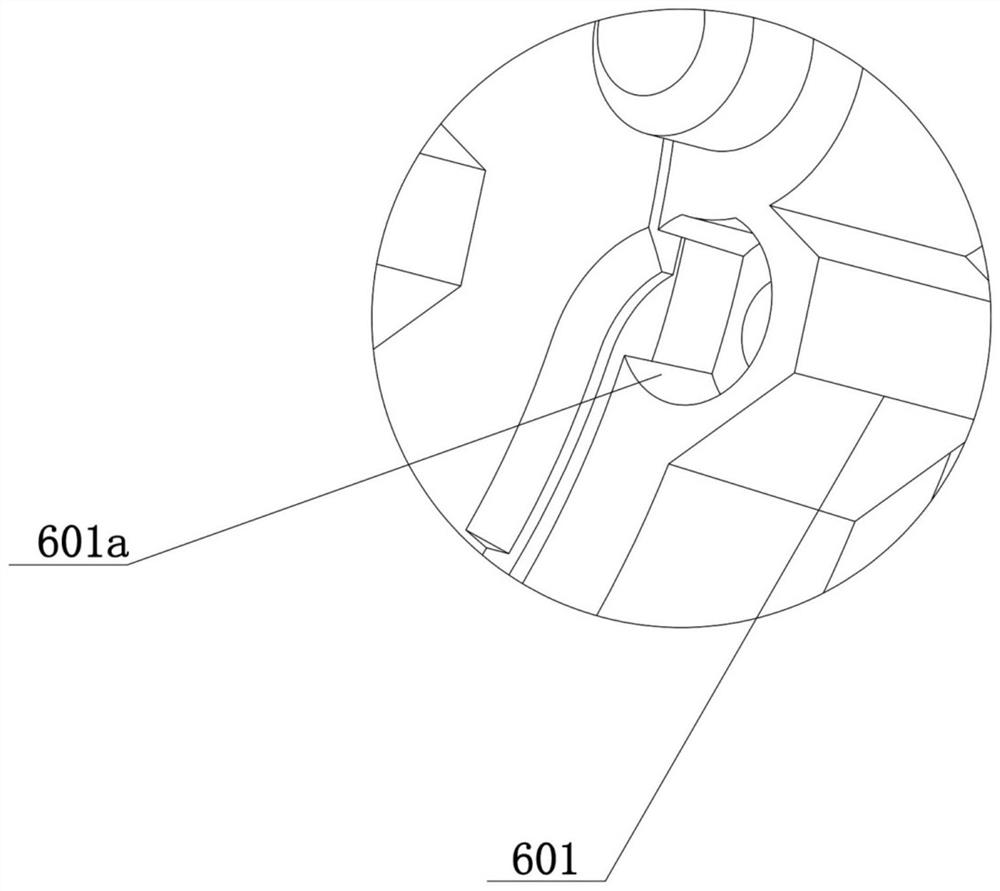

[0073] Such as Figure 5 to Figure 13 As shown, in this embodiment, on the basis of the above-mentioned embodiment 1, one of the optimized designs is made, and the mounting and dismounting parts 6b of the front end retainer 601 and the rear end retainer 602 are provided with opposite first slots 601b and second slots respectively. Two slots 602b, the sensed element 7 and the sensing element 8 are installed in the first slot 601b and the second slot 602b respectively, through the above settings, the sensed element 7 and the sensing element 8 can always be fixed in one and the front end The relatively fixed positions of the frame 601 and the rear end holder 602 avoid the situation that the induction element 8 in the drive handle 1 cannot sense the induction element 8 when the front end holder 601 is fixed on the drive handle 1 along with the working head 5 .

Embodiment 3

[0075] Such as Figure 6 and Figure 7 As shown, in this embodiment, one of the optimized designs is made on the basis of the above-mentioned embodiment 1. The driving handle 1 includes a left casing 101 and a right casing 102 which are arranged side by side and have through grooves formed inside, and the two through grooves are on the left The housing 101 and the right housing 102 are fixed to form a through cavity, so as to accommodate the motor 4 , the sensing element 8 , the switch 15 and the controller 3 in the through cavity.

[0076] Further, the through cavity includes a first open end 1a located on the upper part of the left housing 101 and the right housing 102, and the first open end 1a is closed by the limiting part 6a of the assembly and disassembly assembly 6, so that the motor 4 is sealed to the driving handle 1 the upper end.

[0077] Further, the through cavity also includes a second open end 1b located at the bottom of the left housing 101 and the right hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com