Potato thickness adjustable slicing machine

An adjustable, potato technology, applied in metal processing and other directions, can solve the problems of inconvenient collection, inability to cut potato chips of different thicknesses, etc., and achieve the effect of good reset and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

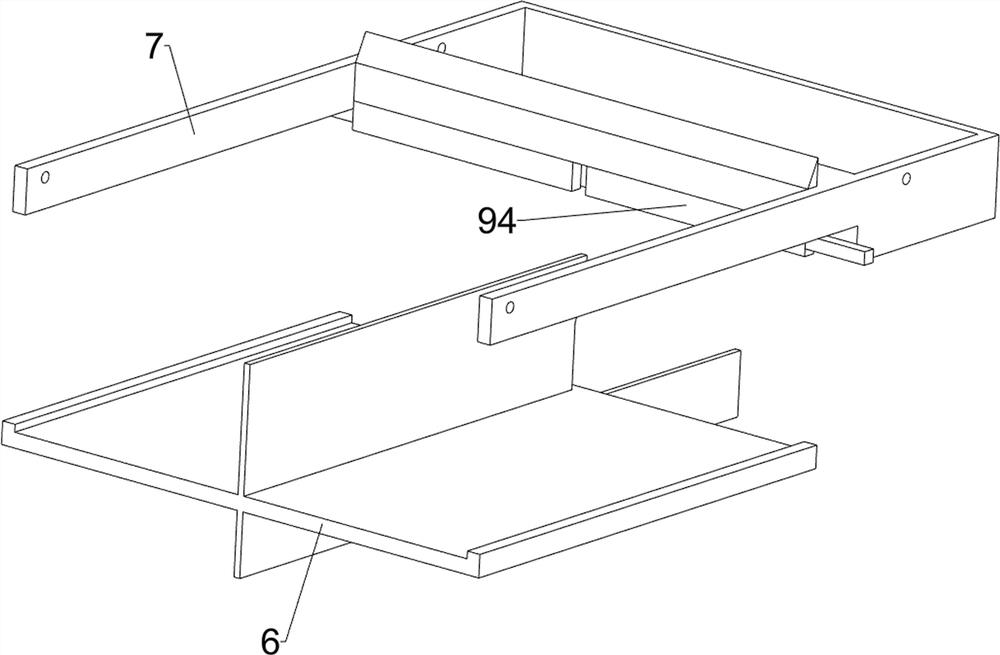

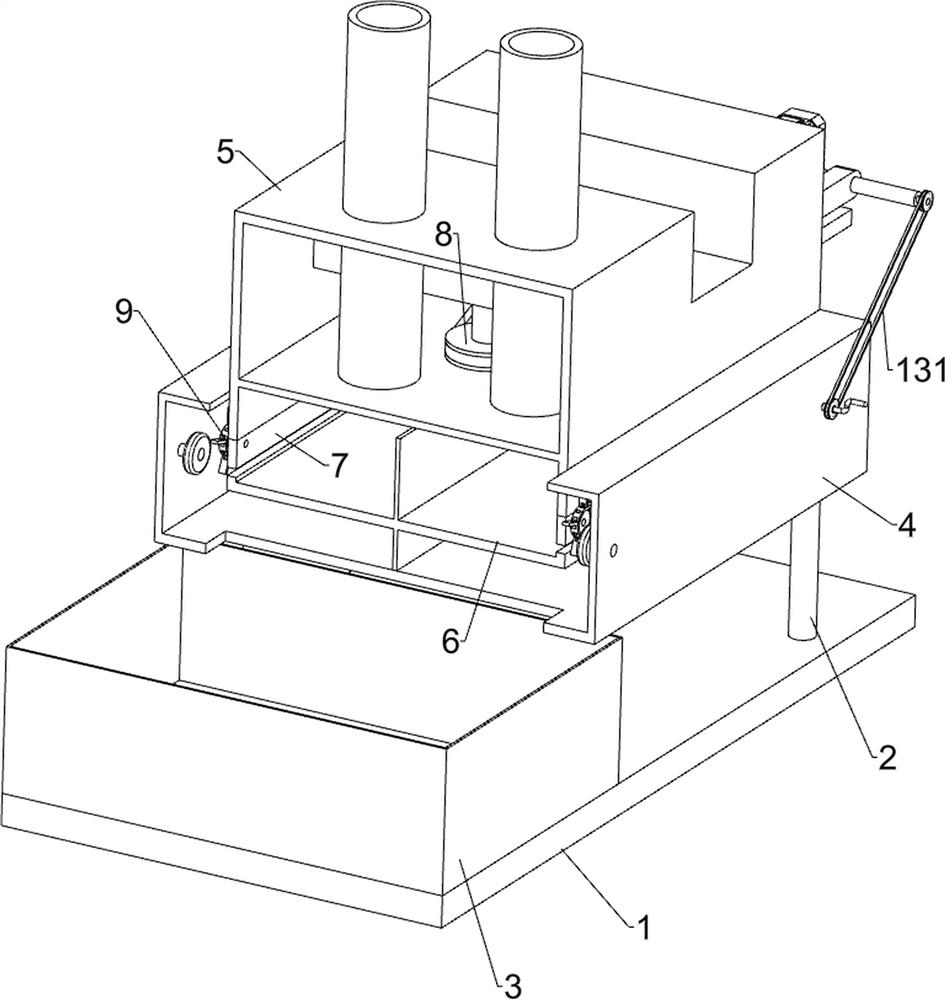

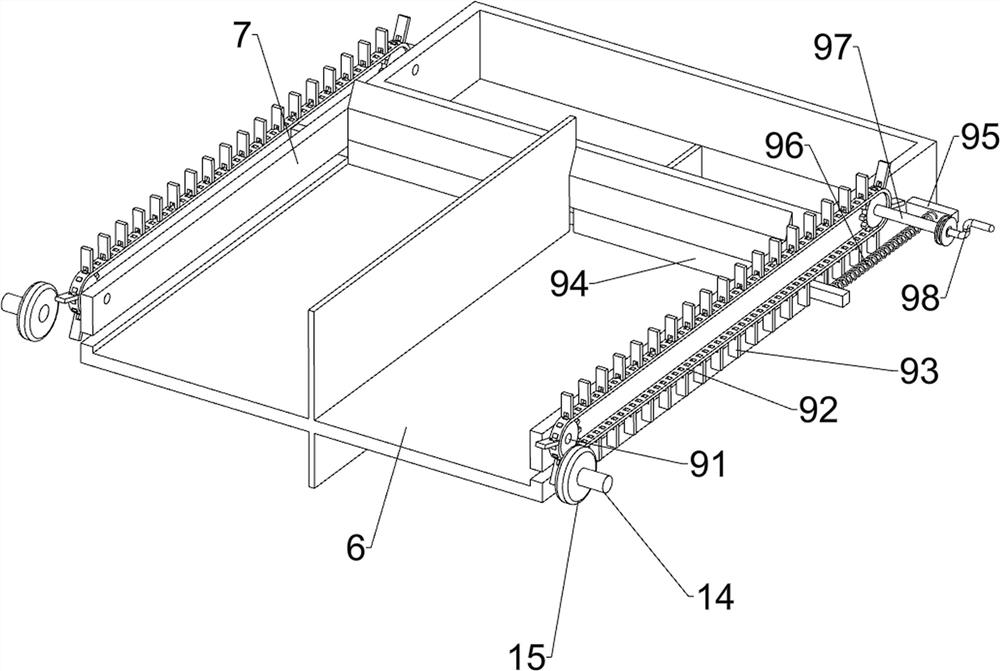

[0023] A potato slicer with adjustable thickness, such as Figure 1-5 As shown, it includes a bottom plate 1, a support column 2, a collection frame 3, a charging box 4, a mounting frame 5, a cross bracket 6, a first fixing plate 7, a slicing mechanism 8, and a feeding mechanism 9, and the top right side of the bottom plate 1 is front and rear The support column 2 is symmetrically fixedly connected, the top left side of the bottom plate 1 is provided with a collection frame 3, the top of the support column 2 is provided with a charging box 4, the charging box 4 is provided with a mounting frame 5, and the middle part of the charging box 4 is provided with The cross bracket 6, the cross bracket 6 is located below the mounting frame 5, the bottom of the mounting frame 5 is provided with a first fixed plate 7, a slicing mechanism 8 is provided between the first fixed plate 7 and the mounting frame 5, and the first fixed plate 7 is provided with Dial mechanism 9.

[0024] When pe...

Embodiment 2

[0030]On the basis of Example 1, such as figure 1 , figure 2 and Figure 4 As shown, it also includes a support plate 10, a second rotating rod 11, a second bevel gear 12, a block 13 and a second belt conveyor 131, and the front part of the right side of the mounting frame 5 is fixedly connected with a support plate 10, and the support plate 10 The second rotating rod 11 is arranged on the top in a rotating manner, and the output shaft at the rear end of the second rotating rod 11 and the front side of the speed regulating box 88 is provided with a second bevel gear 12, and the two second bevel gears 12 are meshed. A block 13 is provided at the front end of the rotating rod 11 , and a second belt transmission device 131 is provided between the second rotating rod 11 and the first rotating rod 97 .

[0031] When people start the servo motor 810, the servo motor 810 drives the output shaft on the front side of the speed control box 88 to rotate, and the output shaft on the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com