Forming die and method for ceramic, rubber and steel three-in-one lining plate

A molding die, three-in-one technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of unstable quality, high price, low efficiency, etc., and achieve significant economic benefits and low energy consumption. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to facilitate the understanding of the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

[0031] Unless otherwise defined, all technical terms used hereinafter have the same meanings as commonly understood by those skilled in the art. The terminology used herein is only for the purpose of describing specific embodiments, and is not intended to limit the protection scope of the present invention.

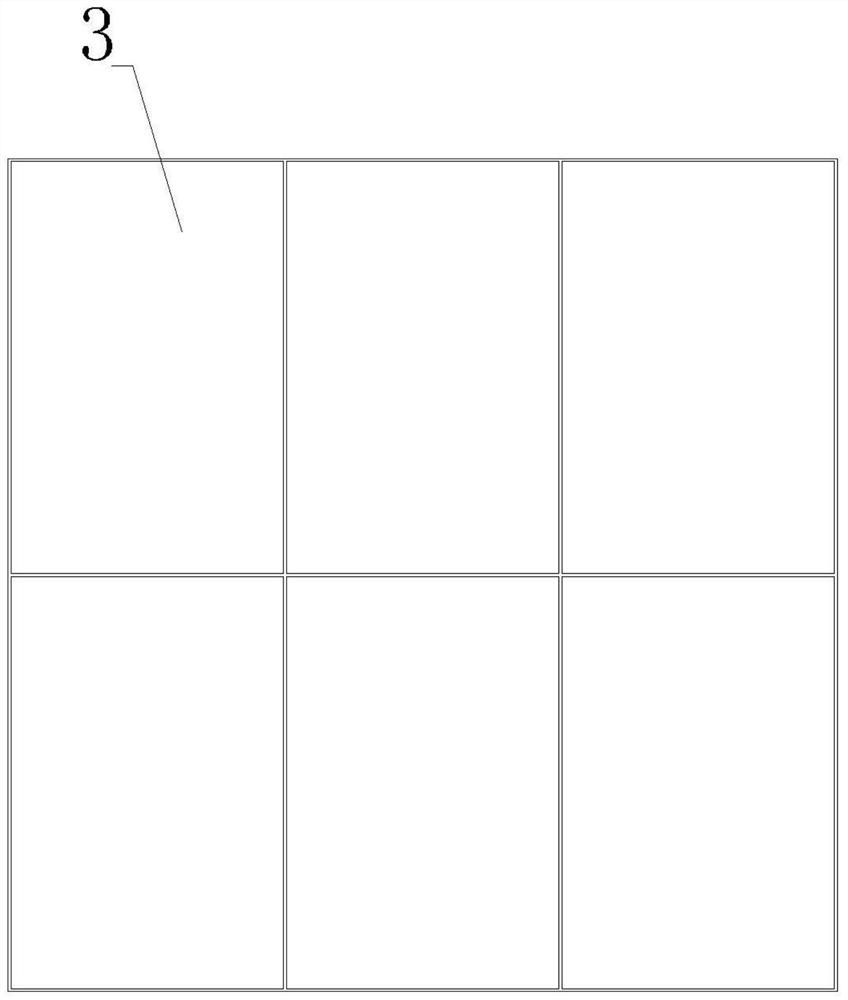

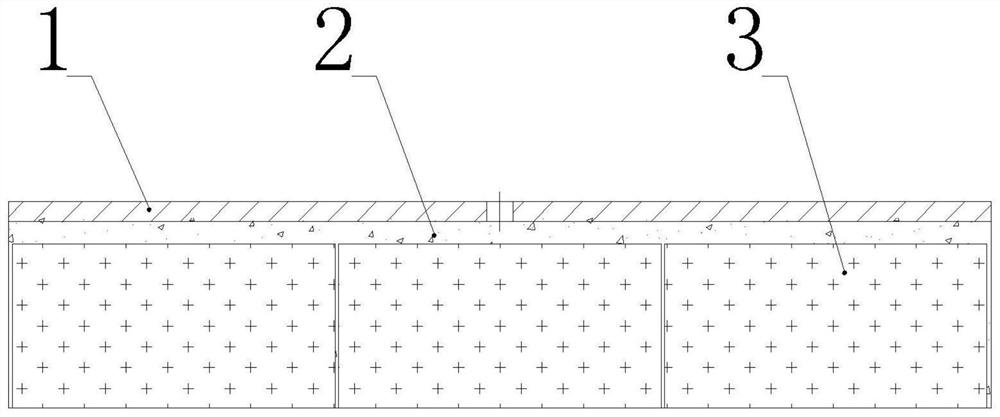

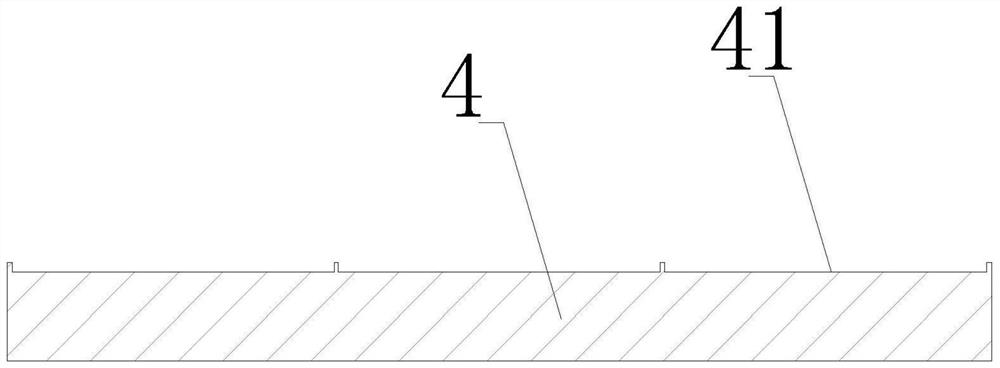

[0032] Such as figure 1 with 2 , the three-in-one liner plate of injection vulcanized ceramics, rubber, and steel plate according to a specific embodiment of the present invention includes a steel plate 1, a ceramic sheet 3, and a rubber layer 2 formed by vulcanization in the middle of the two, so as to connect the steel plate 1 and the ceramic sheet fixed. Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com