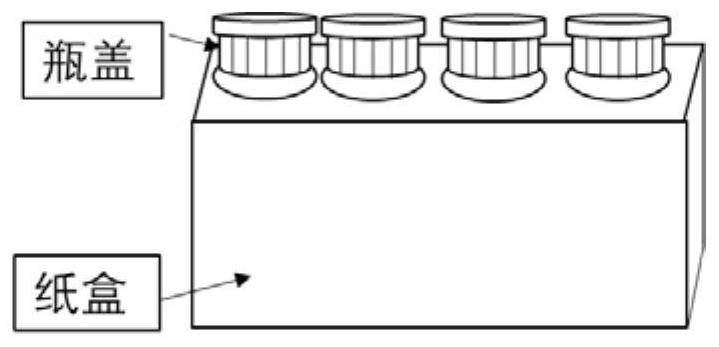

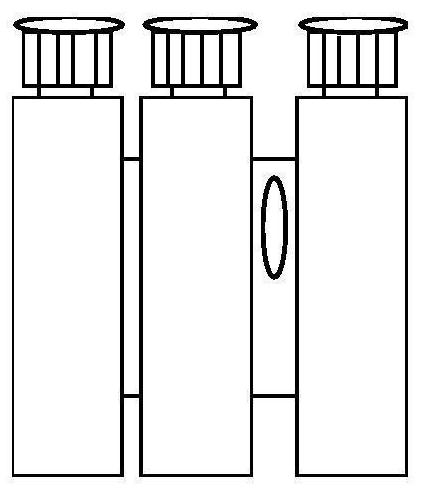

Automatic multi-cap simultaneous cap screwing machine and cap screwing method

A capping machine and automatic technology, applied in screw caps and other directions, can solve the problems of leakage, time-consuming capping and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

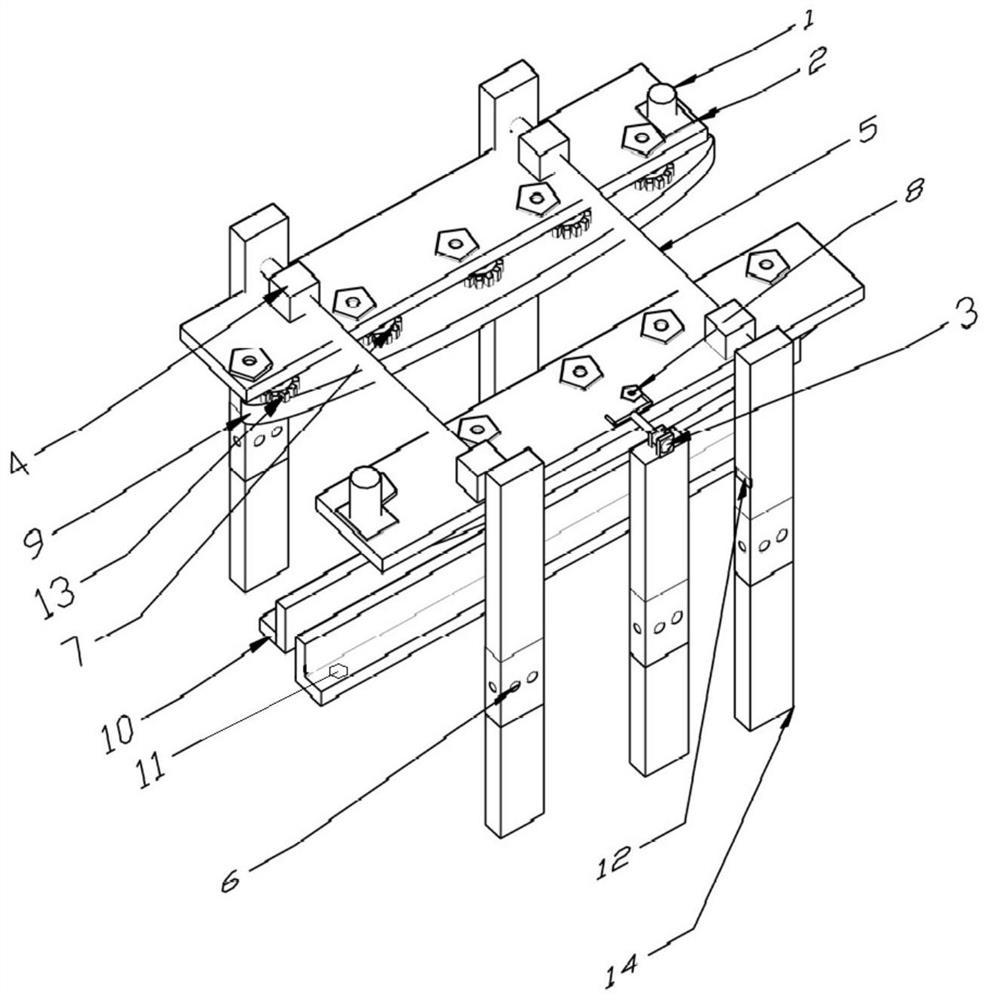

[0025] image 3 As shown, the present invention includes: a positioning guide rail 10, which is used to convey combined packaging bottles; a screw cap friction belt 9, located above the positioning guide rail 10, is provided with two horizontal ones;

[0026] Set in pairs above the two screw cap friction belts 9, linked with the screw cap friction belts 9, for tightening the cover and rotating under the operation of the screw cap friction belts 9, driving the cover to rotate; the mounting plate is provided with two , the capping friction belt 9 is installed below the mounting plate, and the supporting adjustable spacing support wheel 7 is also installed below the mounting plate;

[0027] There are two linear bearing sets 4, which are respectively connected to two mounting plates for adjusting the distance between the mounting plates;

[0028] The slide bar 5 is embedded inside the two linear bearing groups 5, and the two ends of the slide bar 5 are connected to two height-adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com