LED assembly, quantum dot LED light-emitting part, quantum dot LED packaging structure and display equipment

A technology for LED components and LED packaging, applied in electrical components, semiconductor devices, circuits, etc., can solve problems such as the decline of quantum dot light conversion efficiency, quenching and blackening of quantum dot packaging layers, and achieve a simple and fast product manufacturing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

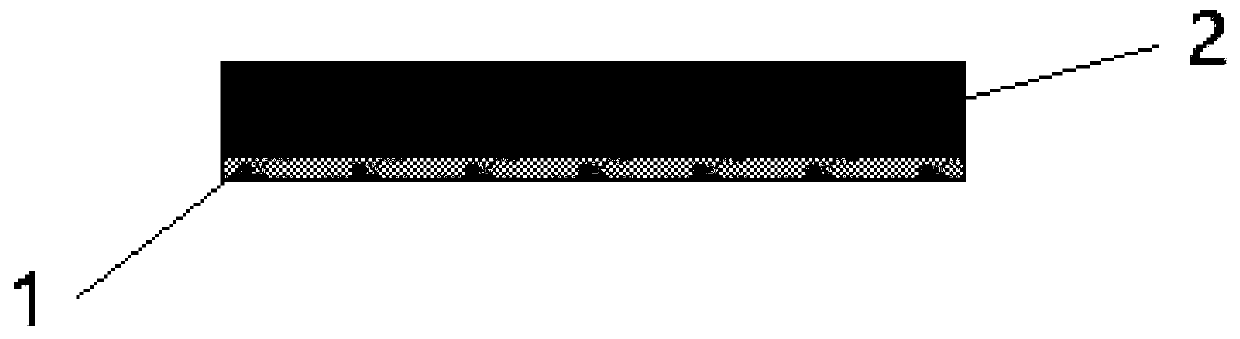

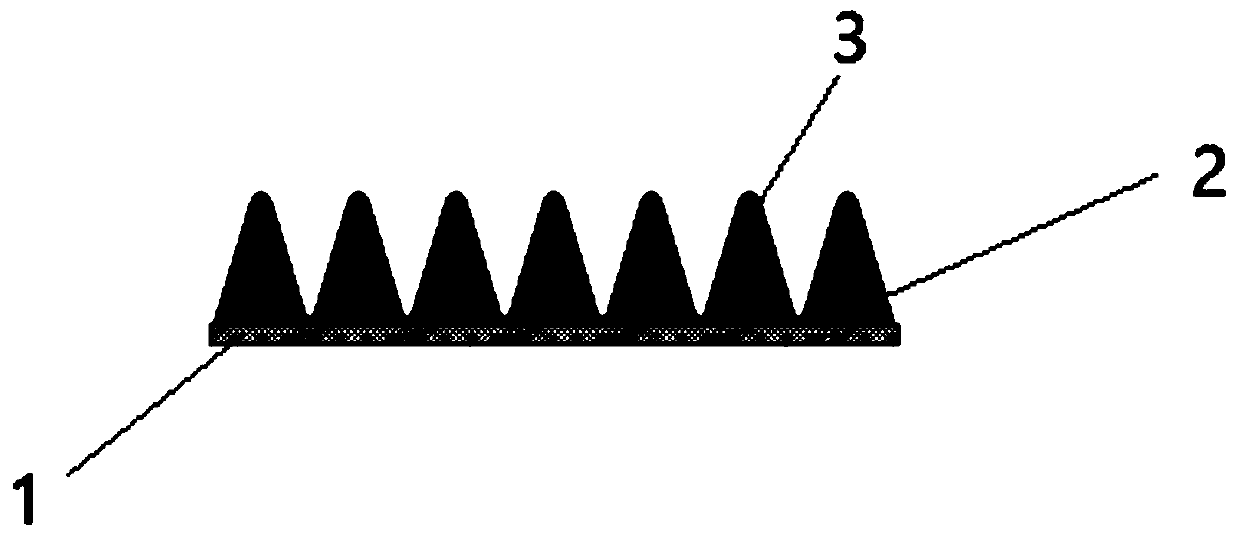

[0050] The application also provides a method for preparing an LED component, such as Figures 1 to 4 shown, including the following steps:

[0051] Provide LED chip 1;

[0052] disposing an organic polymer or an inorganic substance on the surface of one side of the LED chip 1;

[0053] Etching the organic polymer or inorganic substance so that it has a porous structure 4;

[0054] Before and / or after the etching treatment, several protrusions 3 are formed on the surface of the organic polymer or inorganic substance through a surface treatment process to obtain a light-transmitting quantum dot accommodation structure.

[0055] It is worth mentioning that the above method uses etching to form a porous structure 4 to construct a light-transmitting quantum dot accommodation structure with high light transmittance, so that the quantum dots can be arranged in a specific shape in a three-dimensional space. The multiple refraction guide provided by the light prevents the quantum d...

Embodiment 1

[0079] see Figure 1~5 , take the LED chip 1, and coat a layer of polymethyl methacrylate on it to form a transparent organic polymer layer 2, the thickness of which is 100 μm, and then use nanoimprinting to carry out the surface structure of the organic polymer layer 2 chemical treatment to form regular protrusions 3 with a size of 65 μm and an adjacent spacing of 20 μm, and then use a solvent (including but not limited to ethyl acetate, toluene, etc.) to etch them to form a porous structure 4, Finally, hydrophobic treatment is performed on the porous structure 4 .

[0080] see Figure 7-10 , cut the LED assembly obtained above according to a certain size to obtain microchips 9 . Place the microchip 9 in the middle of the LED bracket 7, and drip the CdSe quantum dot solution to it, wherein the viscosity of the selected quantum dot solution is 48cps; after ensuring that an appropriate amount of the quantum dot solution penetrates into the porous structure 4, dry it to make t...

Embodiment 2

[0082] Take the LED chip 1, coat it with a layer of polydimethylsiloxane to form a transparent organic polymer layer 2, the thickness of which is 100 μm, and then use nanoimprinting to carry out the surface structure of the organic polymer layer 2 Chemical treatment to form regular protrusions 3 with a size of 40 μm and an adjacent spacing of 10 μm, and then use a solvent (including but not limited to ethyl acetate, toluene, etc.) to etch them to form a porous structure 4 .

[0083]The LED assembly obtained above is cut according to a certain size to obtain a microchip 9 . Microchip 9 is placed in the middle of LED support 7, and it is carried out the instillation of CdSe quantum dot solution (quantum dot solution identical with embodiment 1), wherein the quantum dot solution viscosity of selection is 10cps; When guaranteeing an amount of quantum dot After the solution penetrates into the porous structure 4 , it is dried to evaporate the solvent contained in the quantum dot so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com