A kind of preparation method of zinc gallate mesoporous nanosphere

A technology of zinc gallate and nanospheres, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of easy aggregation, uneven size of nanomaterials, low drug loading rate, etc., to achieve enhanced afterglow performance, The effect of high drug loading rate and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

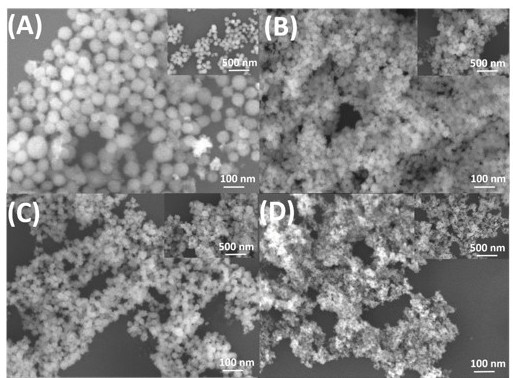

[0021] a) Preparation of uniform nano-silicon spheres (MSN-1) with regular mesoporous pore structure (diameter about 130 nm, and mesopore diameter of 6.8 nm; b) Preparation of ion sources containing gallium nitrate, zinc nitrate and chromium nitrate The mixed solution and the stoichiometric ratio of Ga, Zn, Cr input amount is 1:2:0.0006; c) the mixed solution of MSN-1 and metal ion nitrate is mixed uniformly at a mass ratio of 50:1, d) at 800 o Calcined at high temperature for 3h to obtain ZnGa 2 o 4 :Cr 3+ -composite of MSN-1; e) NaOH solution (40% by mass) and ZnGa 2 o 4 :Cr 3+ The complex of -MSN-1 is in a mass ratio of 1:0.01 in a ratio of 40 o Stirring at C for 12 h, etching to remove MSN-1, and then obtaining raspberry-like mesoporous ZnGa 2 o 4 :Cr 3+ , Si 4+ nanospheres. The product SEM picture is as follows figure 1 A, the synthesis process is as follows figure 2 .

example 2

[0023] a) Preparation of uniform nano-silicon spheres (MSN-1) with regular mesoporous pore structure (diameter about 130 nm, and mesopore diameter of 6.8 nm; b) Preparation of ion sources containing gallium nitrate, zinc nitrate and chromium nitrate The mixed solution and the stoichiometric ratio of Ga, Zn, Cr input amount is 1:2:0.0006; c) the mixed solution of MSN-1 and metal ion nitrate is mixed uniformly at a mass ratio of 50:1, d) at 800 o Calcined at high temperature for 3h to obtain ZnGa 2 o 4 :Cr 3+ -composite of MSN-1; e) NaOH solution (40% by mass) and ZnGa 2 o 4 :Cr 3+ The complex of -MSN-1 is in a mass ratio of 1:0.1 in a ratio of 40 o Stirring at C for 12 h, etching to remove MSN-1, and then obtaining raspberry-like mesoporous ZnGa 2 o4 :Cr 3+ , Si 4+ nanospheres. The product SEM picture is as follows figure 1 b.

example 3

[0025] a) Preparation of uniform nano-silicon spheres (MSN-1) with regular mesoporous pore structure (diameter about 130 nm, and mesopore diameter of 6.8 nm; b) Preparation of ion sources containing gallium nitrate, zinc nitrate and chromium nitrate The mixed solution and the stoichiometric ratio of Ga, Zn, Cr input amount is 1:2:0.0006; c) the mixed solution of MSN-1 and metal ion nitrate is mixed uniformly at a mass ratio of 50:1, d) at 800 o Calcined at high temperature for 3h to obtain ZnGa 2 o 4 :Cr 3+ -composite of MSN-1; e) NaOH solution (40% by mass) and ZnGa 2 o 4 :Cr 3+ -The complex of MSN-1 is in a mass ratio of 1: 1 in a ratio of 40 o Stirring at C for 12 h, etching to remove MSN-1, and then obtaining raspberry-like mesoporous ZnGa 2 o 4 :Cr 3+ , Si 4+ nanospheres. The product SEM picture is as follows figure 1 c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com