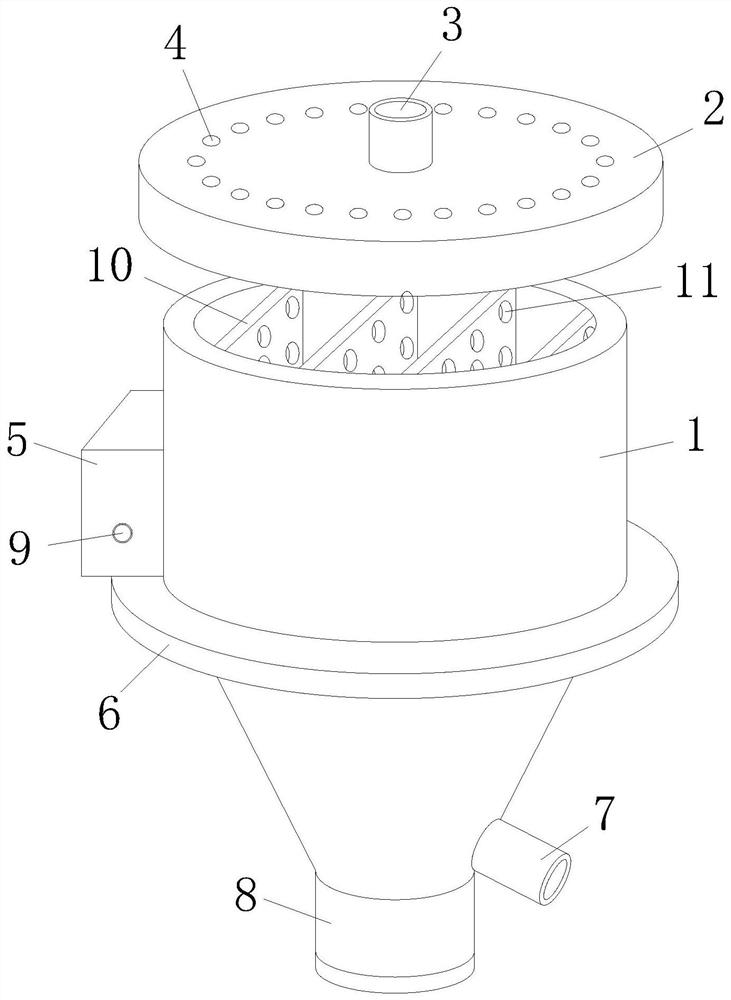

Heavy metal processing wastewater treatment system

A technology for processing wastewater and treatment system, applied in water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of low wastewater purification efficiency, difficulty in cleaning equipment, affecting purification effect, etc. Difficulty of cleaning, improve the efficiency of sewage purification, improve the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

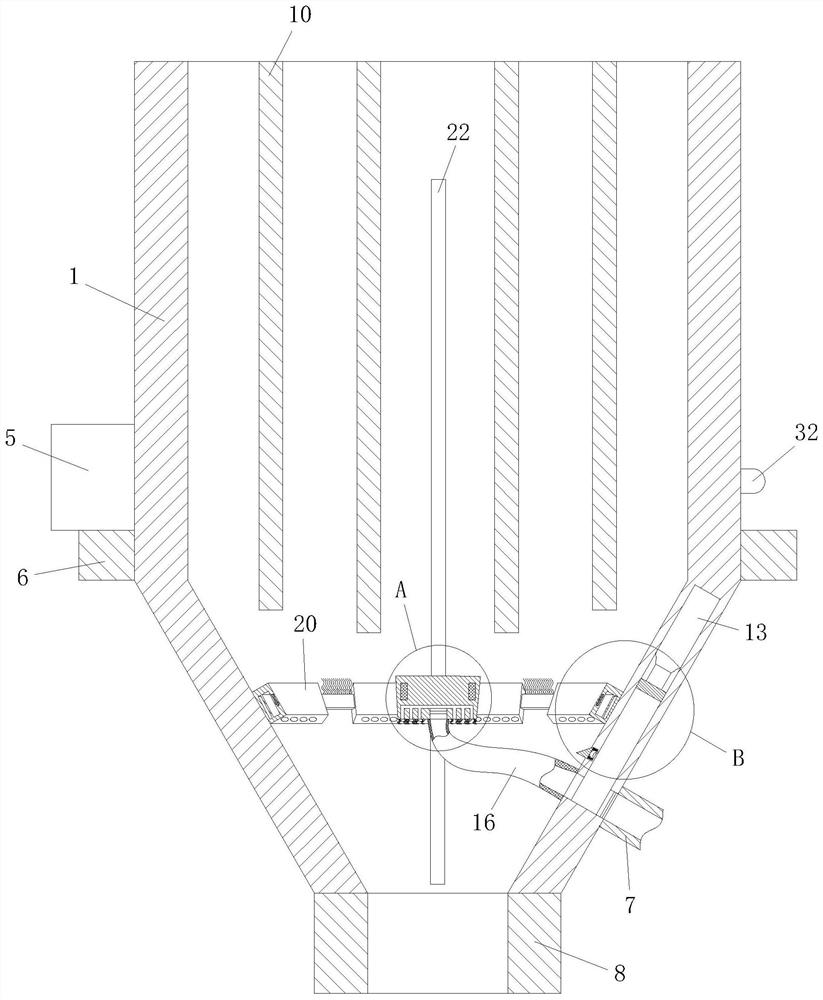

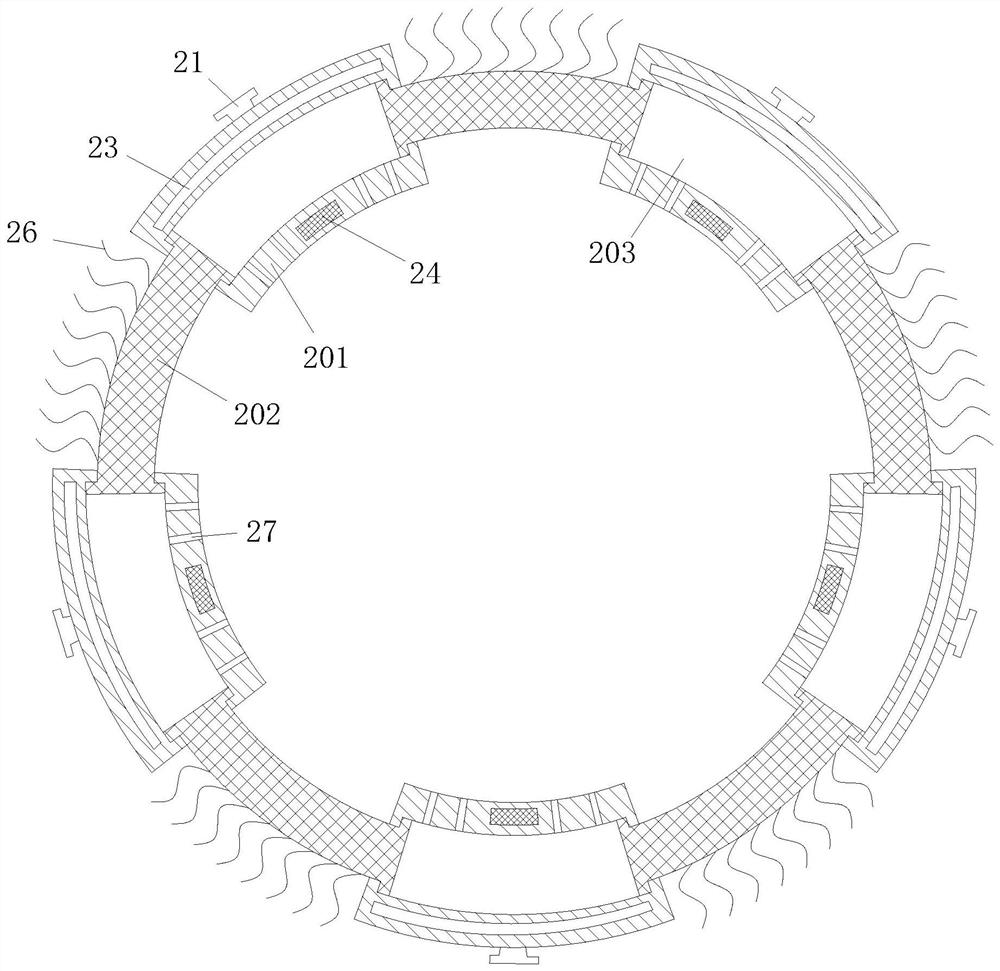

[0024] As an embodiment of the present invention, the lower surface of the floating block 15 is fixed with evenly arranged soft hairs 19; the surface of the floating block 15 is wrapped with a metal mesh; During the process, the water entering the flow hole 18 is filtered through the soft hair 19 to improve the cleanliness of the water entering the flow hole 18. At the same time, through the metal mesh on the surface of the floating block 15, when the floating block 15 contacts the electrode plate 10, part of the current enters the metal mesh. In the net, while improving the wastewater purification effect, it prevents the sludge from adhering to the surface of the floating block 15, causing the gravity of the floating block 15 to change, which is not conducive to use. Sludge is inhaled during the process of depleting the water, resulting in a low degree of water purification, thereby improving the degree of purification and improving the purification efficiency.

[0025] As an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com